More recently, gas appliances were connected directly to a gas pipe. Despite the fact that the method was considered safe, it had significant drawbacks, the main one of which was the impossibility of moving the gas stove or boiler to a comfortable position. Currently, it is recommended to use flexible hoses for installation, among which the safest and most reliable is a bellows gas supply, which is a flexible corrugated hose.

Content

- 1 The main types of gas hoses: their advantages and disadvantages

- 2 Bellows gas hose: main advantages

- 3 Bellows gas supply: what it is, the main characteristics

- 4 Major manufacturers of bellows gas supply

- 5 What is a dielectric gas insert: main purpose

- 6 Basic rules for the safe operation of flexible gas pipes

The main types of gas hoses: their advantages and disadvantages

Modern manufacturers offer a large selection of flexible gas hoses, which differ in material and workmanship, which affects the final cost of the finished product. You should not save on the purchase, since only the correctly selected hose will avoid such a problem as gas leakage, which can lead to serious consequences. Currently, in addition to bellows hoses, manufacturers offer other types of products:

- oxygen;

- rubber-fabric;

- reinforced rubber PVC;

- rubber, reinforced with a metal sheath.

Oxygen hoses are considered obsolete. In domestic conditions, they are rarely used due to the short service life and not very attractive appearance. Most often, an oxygen hose for gas cylinders is installed if it is necessary to place the tank as far as possible from the gas stove. However, their main area of application is the transportation of gas mixtures such as butane, propane and acetylene.

The main advantages that distinguish the product are the ability to withstand high pressure up to 20 atm., Ease of installation and low price.Due to the rubber hose, it does not conduct electricity, which reduces the likelihood of sparks.

Important! The main disadvantage of the oxygen hose is the destruction of the braid when hot oily solutions hit the surface.

A significant drawback of hoses with a metal braid is the impossibility of visual control over the condition of the rubber layer

Rubber-fabric flexible hose is the cheapest type of gas hose, which has an extremely short service life - up to 5-7 years. However, most experts are inclined to believe that it is better to change it every 3-4 years. Other disadvantages include a low level of hardness and a small temperature range at which it is permissible to use the product - from -10 to +50 ° C. Due to its structure, the hose bends well and is characterized by a high level of electrical insulation.

Slightly better quality has a rubber hose with a metal braid, which has an optimal price-performance ratio. The product consists of special vulcanized rubber and polymer materials, which are braided with steel threads on top. The main disadvantage is the ability to become electrified, which can lead to failure of gas equipment or (even worse) to a fire. To avoid this, a dielectric sleeve is used. The main advantages of a rubber-fabric flexible gas line:

- low price;

- easy installation;

- the ability to use at temperatures from -35 to +50 ° С;

- big choice.

The reinforced PVC sleeve occupies a high position in the market due to the fact that it has a long service life (up to 12-15 years) and is designed for heavy loads - up to 0.63 MPa. The maximum length of the gas hose is 5 m, while the shortest version is only 0.4 m. Due to the use of polyvinyl chloride for production, the hose does not transmit electric current, bends well and is characterized by high quality.

Bellows gas hose: Main advantages

The bellows is a flexible corrugated tube that is particularly rigid. This hose is the most reliable. It is this type of flexible hose that is recommended for the installation of equipment by gas services. This is due to the fact that it is characterized not only by a high degree of safety, but also by the longest service life. In addition, it can withstand the heaviest loads generated by the gas flow. Therefore, if in shopping malls you ask which gas hose is better, then, most likely, they will offer to buy a bellows.

Helpful advice! Regardless of which one decided to purchase a gas flexible hose: metal, PVC or bellows, it must be taken into account that it must be accompanied by a passport and certificates confirming its quality and safety of use. The minimum section of the hose must not be less than 10 mm, otherwise normal operation of the gas equipment will be impossible.

Despite the fact that the price of a bellows hose for gas is several times higher than the cost of other options for flexible hoses, it is still considered the leader among other types of hoses used to connect gas stoves and boilers. The price is influenced not only by the manufacturer, but also by the length of the product, as well as the availability of additional options. So, some types of products are equipped with an automatic temperature sensor, which, in the event of violations, independently cuts off the gas supply, which can prevent leakage and fire.

Bellows gas connection: what is it, main characteristics

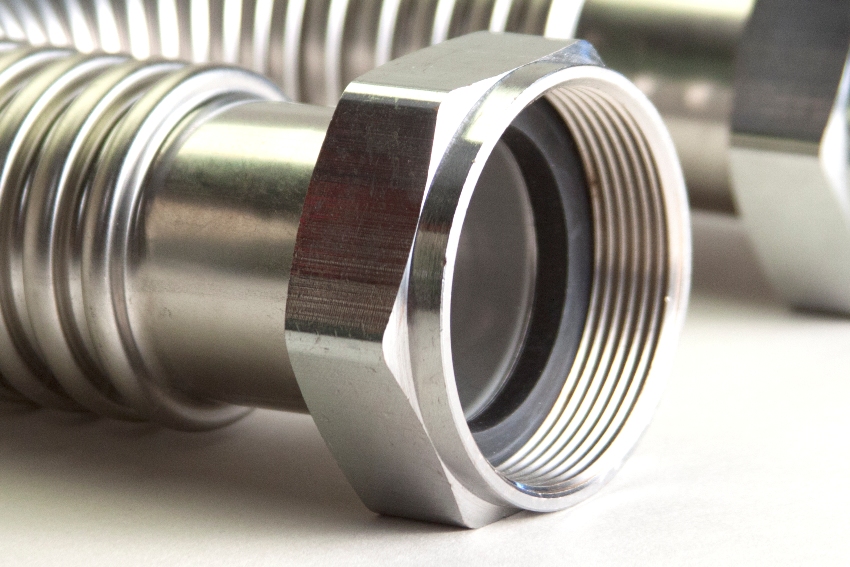

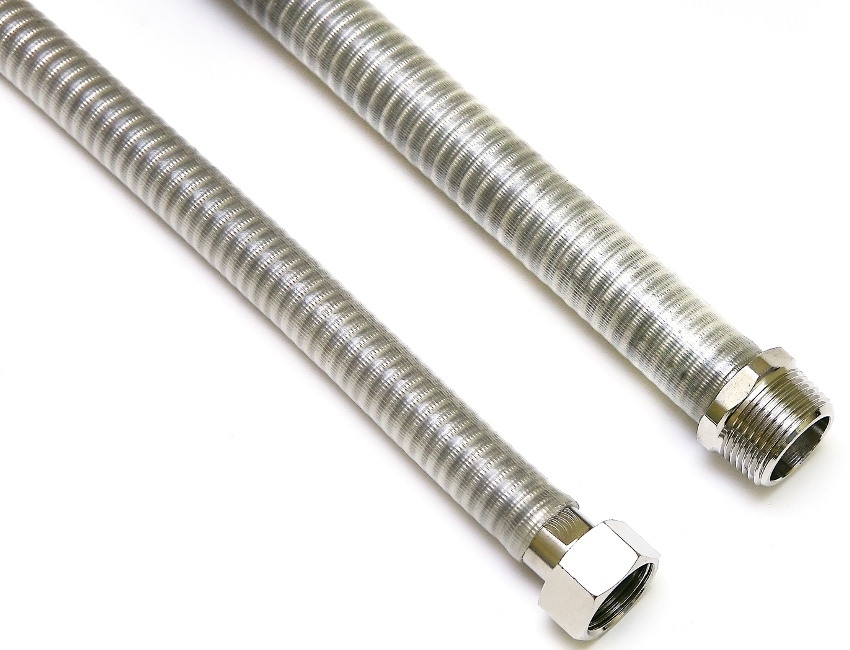

Bellows flexible hose is a corrugated metal sleeve made of high-quality stainless steel.Thanks to this feature, the hose can be stretched and lengthened. At the ends of the device there are usually 2 nuts, which are used to connect gas equipment to the fuel supply pipe, or a nut and a union. In the production of fittings, stainless steel is also used, which is not subject to corrosion and rust.

Union nuts are used to connect a flexible bellows-type gas line to the equipment and directly to the gas pipe. It is imperative that it is recommended to install a metal gasket made of copper or aluminum between the inlet pipe and the product - sometimes special plastic is used for this purpose.

If you choose a bellows-type gas hose made not by European, but, for example, Chinese or Turkish manufacturers, then it should be noted that instead of stainless steel they use carbon steel, which is more fragile and more susceptible to destruction. Therefore, when buying a gas supply, it is recommended to give preference to products with the following markings:

- stainless steel hose: AISI 316;

- steel fitting: AISI 304 or 303.

Experts advise, when choosing a hose, it is imperative to check that both the fitting and the corrugation are made of the same material. This is due to the fact that each material has a certain density and strength. If different types of metal are welded together, an electrochemical reaction can occur that can destroy the welded joint, which will lead to a loss of strength of the device.

You should not purchase products where the fitting is attached to the corrugation using an adhesive mixture. You should also not buy hoses in which the fitting is soldered using tin or silver. In this case, the products will not serve for a long time, and their strength can also be questioned. Therefore, when buying, you should pay attention to the fact that the price of a gas hose should not be suspiciously low.

Main technical characteristics of gas bellows hoses

Like any other product, the bellows gas hose has specific features and parameters that distinguish it from other options. Among the main characteristics are the following:

- The products can be used in a wide range of temperature differences - from -50 to + 250 ° С, and at any temperature within these limits, the hose does not lose its qualities.

- The maximum pressure for which the sleeve is designed is 6 atmospheres. It should be borne in mind that according to the norms, the maximum pressure at which gas can enter the living quarters is 0.03 atm. From this we can conclude that the safety margin of the product is 200%.

- Due to the corrugated surface, the product can be lengthened 2 times relative to its original size. This ability is ensured by the use of high-quality stainless material, which has been pre-annealed.

- Long period of operation. The service life of the bellows gas hose is 20-25 years, although some manufacturers provide a 30-year warranty.

Helpful advice! Despite the fact that the product can be stretched, it is not recommended to double it: the more the hose is stretched, the more its rigidity decreases. Therefore, the maximum stretch that can be applied to the product is 50%.

A very important point when choosing a bellows-type metal gas hose is the availability of a quality certificate confirming that the product is intended for use with explosive substances.The passport must indicate the fact that the product has been tested and meets all safety requirements. It is necessary to pay attention to the manufacturing time and the period of operation of the hose.

Major manufacturers of bellows gas supply

The Italian company Emiflex, which also passed certification in Russia, is considered the market leader in the production of bellows hoses. After some research, approval for the use of hoses from this company was given by the state organization Rostest. In addition, the manufacturer received a permit from Gosgortekhnadzor, which approved the use of products for connecting domestic gas in residential premises.

The Emiflex gas hose has the following technical features that make the company a market leader:

- the product is designed to work with natural and liquefied gas;

- the maximum gas pressure for which the product is designed is 7 atm .;

- the device can be operated without loss of properties at temperatures from -20 to +100 ° С;

- thickness of the metal bellows hose - 2.1 cm;

- it is permissible to stretch the product twice in relation to its original length;

- hoses of various cross-section diameters are available - 1, 1/2, 3/4 (in inches);

- among the types of fasteners, options such as nut-nut and nut-union are available;

- The outer cover of the bellows protects the product from chemical detergents.

The maximum length of the Emiflex gas hose, which is certified in Europe, is 2 meters. For the production of devices, stainless steel is used, which is marked with AISI 316 L. In addition, an aluminum gasket is included with the hose, which is used during installation. The manufacturer draws attention to the fact that sleeve lengthening is possible only during installation. It is unacceptable to stretch the hose during operation.

Another certified Italian manufacturer on the territory of the Russian Federation is Idrosapiens S.R.L., which also has a European quality certificate confirming that the product meets the standards of domestic use.

Gas hoses of this company guarantee high-quality and safe operation for 15 years. At the same time, longer use is not excluded, but without a guarantee from the manufacturer. Below is a table showing the price of gas hoses from Italian manufacturers.

| Size, inch | Length, m | Manufacturer and price, rubles | |

| Emiflex | Indrosapiens | ||

| 1/2 | 0,5 | 1350 | 1300 |

| 0,75 | 1700 | 1500 | |

| 1 | 1850 | 1650 | |

| 2 | 3800 | 3450 | |

| 3/4 | 0,5 | 1700 | 1550 |

| 0,75 | 2000 | 1750 | |

| 1 | 2500 | 2150 | |

Features of flexible bellows gas supply stainless steel. 1/2 and 3/4 Belarusian manufacturer

A more affordable (in terms of price) certified manufacturer of flexible hoses in the Russian market is the Belarusian company Zurflex. It produces products designed to connect gas stoves, hobs and gas equipment for individual heating. The Belarusian manufacturer has a bellows line for 1/2 and 3/4 gas with a nut-nut connection option (one differs with an internal thread, and the other with an external thread) or a nut-union. The temperature at which it is permissible to use the product varies in the range from - 15 to + 150 ° С. Other product parameters:

- recommended working pressure - 30 atm., and maximum - 100 atm .;

Related article:

Gas hose for gas stove: the right choice for safety

The main types of products, their advantages and disadvantages. Expert advice on hose selection. Features of secure connection.

- the minimum bending radius that can be created manually is 45 mm;

- inner diameter of the sleeve - 12 mm, outer diameter excluding coating - 17 mm;

- used in the manufacture of stainless steel grade A151 3041;

- steel corrugation thickness - 0.15 mm;

- the maximum length of the gas hose is 5 meters;

- guaranteed service life - 15 years.

It should be noted that the end fittings and union nuts from this manufacturer are made of carbon steel, but thanks to the chromium-nickel coating, the elements have good strength indicators. Convenience of use and installation of Zurflex products is ensured by the presence of a paronite or aluminum gasket in the kit. The quality assurance is confirmed by a technical passport and an identification sticker located on the front of the package. Prices for Zurflex hoses are presented in the table below.

| Size, inch | Length, m | Price, rubles |

| 1/2 | 3 | 750 |

| 4 | 950 | |

| 5 | 1200 | |

| 3/4 | 2 | 900 |

| 2,5 | 1100 | |

| 3 | 1200 |

How to distinguish a flexible stainless steel gas hose from a fake: selection rules

Due to the popularity of bellows-type gas hoses, counterfeits are often found on the markets, most often from China. At the same time, one should not confuse Chinese products made by order of European firms in compliance with technical norms and rules, and low-quality fakes.

Helpful advice! Many European firms, in order to reduce the cost of the finished product, officially give orders to Chinese factories that produce products that meet quality standards. Such hoses have the necessary certificates and are considered reliable and safe.

The second category of Chinese bellows hoses for a gas stove includes products that are pirated without observing technical standards and using low-quality materials. Handmade hoses are of poor quality, which reduces the level of product safety. Such hoses are often the cause of gas leaks and many other troubles. It is necessary to take into account the fact that even products of dubious quality can have a high price. Therefore, when buying, you should adhere to the following rules:

- choose products only at certified retail outlets;

- pay attention to certificates and passports of hoses;

- do not buy sleeves from a seller who refuses to show product documentation;

- carry out a visual inspection of the product before purchasing;

- in the presence of any defects or violation of integrity, the goods should be discarded.

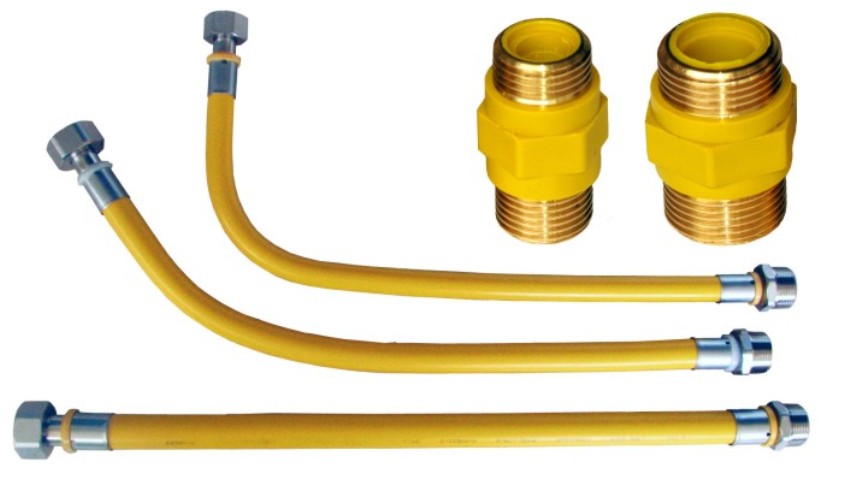

It is imperative to know that gas stoves are connected only using a sleeve, which is characterized by the presence of a yellow mark. The presence of a red or blue marking indicates that the product is intended for plumbing use. It is important to select the correct size for the bellows hose. To do this, measure the distance from the gas pipe to the connected equipment. The sleeve must not sag much or be in tension. It is strictly forbidden to splicate several hoses together.

When buying, you need to pay attention to the method of fastening (union or nut) and choose the right size. If this is a 1/2 bellows gas line, then the fastening must correspond to this parameter. If the stove is electrically ignited, you need to purchase a safe flexible sleeve with an insulator, which is a white plastic ring located between the nuts and the braid, or you should additionally install a dielectric insert.

There are certain criteria for choosing a high-quality flexible liner based on the tasks assigned to this element.

What is a dielectric gas insert: main purpose

The dielectric insert (coupling) is a cut-off fitting that prevents the failure of the gas equipment, which can be caused by the action of a stray current. These currents are generated in the ground due to a breach of the integrity of a household or industrial electrical line. In addition, their source is the railway or tram line. The stray current enters the gas pipeline due to the difference between the resistances of the soil and the metal parts that make up the gas pipeline. It is through the pipeline that the current enters the household gas pipeline.

Another reason for the occurrence of a stray current in the gas system can be poor-quality grounding of household appliances that are in contact with the gas pipe. In general, we can say that there are many reasons for the appearance of wandering currents, and the consequences from them will only be negative. To avoid this problem, a dielectric is used for the gas hose, which cuts between the gas valve and the bellows line to the gas appliance.

The clutch is installed in order, firstly, to prevent the failure of gas equipment, especially if it is a modern technology equipped with a large number of electrical functions. Secondly, the presence of the dielectric prevents the occurrence of a spark, which can trigger a fire or even an explosion. For these reasons, according to the rules of the gas service, a dielectric is necessarily used to connect gas equipment, whether it is a bellows or rubber hose. It is of two types:

- dielectric couplings - are attached between the gas pipeline and the hose that fits the device;

- dielectric bushings are non-conductive bushings mounted at the point of collapsible mating of the gas pipe elements.

Like bellows hoses, inserts are classified by size, which varies depending on the diameter of the threaded part - 1/2, 3/4 and 1. Therefore, a product of the appropriate size can be selected for any type of flexible bellows gas line. The thread of the insert can be both external and internal. Both bushings and couplings have the same strength characteristics and are designed for a pressure of 6 atmospheres.

Interesting information! The dielectric material used in the bushing manufacturing process is polyamide, a non-combustible polymer with a significant resistance of approximately 5 million ohms.

Dielectric couplings - special fittings with threaded ends, mounted between the gas pipeline and the device consuming fuel

How to install the dielectric correctly when performing bellows connection

According to the state safety standard, a dielectric insert must be installed between the gas valve and the bellows line. The main steps to be performed when installing the bushing:

- Close the gas cock. In this case, it is important to leave the gas on the stove on so that it all burns out.

- Take 2 adjustable wrenches: with one it is necessary to hold the valve body, and the second is to twist the nut of the bellows connection, which connects the pipe to the gas appliance.

- Screw any seal onto the free ends of the coupling (the polymer version is better for this), and then manually screw the dielectric into the gas pipeline.

- Again, using 2 keys, one of which is holding the valve, and the second is the coupling, the product is screwed in until it stops. It is important not to overdo it here, so as not to rip the threads and not deform the valve body.

- Screw the nut from the bellows hose onto the other end of the coupling, holding the dielectric with an adjustable wrench, and tighten the connection securely.

After completing all the steps, you need to check the docking place for leaks. For this, either a small brush or a shaving brush is used, which is pre-washed with plenty of soap.A soapy solution is applied to all joints and inlets, after which the gas valve is slowly opened. If even small bubbles or foam suddenly appear, turn off the tap and additionally check the quality of the joints. You can use a gas appliance only if the soap solution does not bubble. Neither matches nor lighters can be used to check the tightness, since in the event of a leak, they can cause tragedy.

How to make a safe gas supply: connection features and safety precautions

Regardless of which hose for the gas stove is chosen: bellows or any other version of the flexible hose, the connection will be carried out according to the same scheme. Before connecting the hose, it is required to unfold the gas device and inspect the back wall of the product. On some models, the gas pipe is marked with “Exit”. Depending on the configuration, the product should be positioned straight or at a slight angle.

In any case, it is important that the hose does not bend too much. To avoid this, corner adapters are additionally purchased, allowing you to change the angle of the sleeve direction. Before carrying out all work, it is necessary to think over the location of the plate and calculate the length of the hose.

Important! Before starting work on installing or replacing the gas hose, turn off the gas valve and do not open it until measures have been taken to identify a possible leak.

The riser is most often located in one of the corners of the kitchen, and a pipe connected by welding with a gas valve fixed to it, to which a flexible bellows gas supply will be attached, is already moving away from it. If the valve has an external thread, then a union nut is used to connect the hose. If there is an internal thread, the sleeve is screwed directly into it.

It is imperative to install a paronite gasket that comes with the tap between the entrance to the gas equipment and the hose. Some experts recommend that you buy a gasket equipped with a metal mesh yourself. If a high-quality crane was chosen, then you can be sure of the reliability of the gasket.

After installing the paronite gasket, the bellows hose is screwed to the plate outlet, and then all connections are tightened with a wrench. At the last stage, it is imperative to conduct a survey for the possible presence of leaks using a soap solution, as in the case of installing a dielectric. If bubbles do not appear, the stove or other device can be safely operated.

Basic rules for the safe operation of flexible gas pipes

Working with central gas supply devices requires special care, because the safety and life of the residents of the house depend on the correct connection and operation. The main rule when using a bellows-type gas hose is its open installation. The sleeve must not be hidden or covered with pieces of furniture or household appliances: the body of the hose, like its connection to the gas pipe, must always be in plain sight.

To hide the device, it is allowed to use a collapsible box, which can be easily disassembled if necessary, but it is better to leave it uncovered. If you hide the product, you may not notice the incipient destruction of the product, which can lead to gas ignition. It is not advised to use paints and varnishes for decorating the hose, which can cause a violation of the integrity of the outer layer.

To connect gas equipment, you must not use a hose that is too long or, conversely, very short.It is important to note that after gas supply, due to the pressure that has arisen, the hose may become slightly shorter, and it is strictly forbidden to stretch the device after installation.

After connecting the stove to the gas pipe, a slight slack in the sleeve is allowed, but care must be taken that there are no kinks or twists. To avoid this, it is recommended to observe the bending radius, which is, on average, three times the diameter. Other important rules:

- Do not allow the hose to be constantly exposed to water or steam, which will oxidize the metal. It is best to place the hob slightly away from the gas pipe.

- If a non-standard thread is installed in the plate, then it is additionally permissible to use an adapter for connection.

- Do not weld or solder near the gas connection. If necessary, a heat shield is installed between the soldering iron and the gas sleeve.

- Before installing the bellows, be sure to pay attention to the presence in the package of documentation confirming the safety of using the product.

- When installing, it is impossible to dock different materials, for example, copper and steel. Steel can only be bonded to steel, and copper to copper or brass.

- Do not use excessive force when tightening the connections to avoid damaging or stripping the threads. To ensure a tighter fit, an FUM tape is used.

- In the absence of experience and self-confidence, you should not carry out work on the self-installation of the gas hose.

Despite the fact that the hoses are guaranteed for 15 to 30 years, it is recommended to inspect the product for cracks at least once a year. Using a soap solution, check the condition of the connections. If any defects are found, the hose should be replaced.

Bellows gas supply is considered one of the types of flexible hoses that are used to connect gas devices to the central pipe. Due to the flexibility and a large selection of hoses of various lengths, there is no need to tie the equipment to the gas riser. Despite the fact that such a hose is several times more expensive than conventional analogues, due to its high quality, safety and long service life, bellows hoses have a large number of positive reviews on the network.