Any owner of a country house or summer house knows how important it is to have an uninterrupted water supply in the absence of a centralized water supply system. In the old days, people got by with wells, from which they drew water in buckets. Today we have added to the wells wells, and the rise of water to the surface is carried out by electric pumps. The pinnacle of technical progress in this area can rightfully be considered a submersible pump for a well with automation. He not only supplies water to the entire household, but also does so without serious human intervention.

Content

- 1 Purpose and types of pumps for supplying water from wells and wells

- 2 Submersible pump for a well with automation

- 3 The device and operation of the automatic water supply system

- 4 How to choose the right submersible pumps for a well with automation

- 5 How to install a submersible pump in a well (video)

Purpose and types of pumps for supplying water from wells and wells

All submersible pumps provide water rise to the surface from a certain depth, which depends on the power of the unit, and its delivery to the consumer. A distinctive feature of such pumps is that they sink partially or completely into the water column. According to the principle of operation, two different types of submersible pumps can be distinguished for wells... With or without automation, they are:

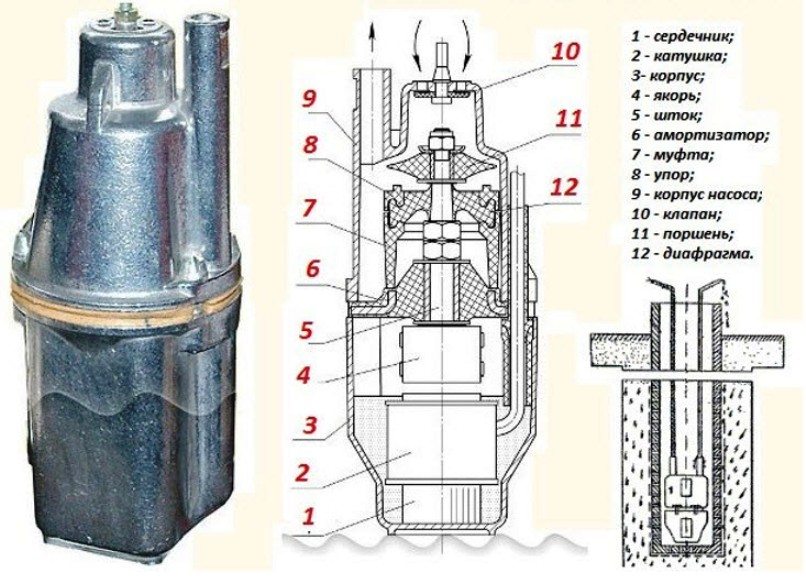

- vibrating. The main working element of such pumps is a movable piston, which creates water pressure during its reciprocating motion. It is provided by the electromotive force of the inductor, to the core of which the piston is rigidly attached through the rod. A 220 V current is applied to the coil, which creates a magnetic field that causes the core to move with the piston. When the piston is retracted, water flows into the working chamber. Having reached the limit point, the piston opens the contacts and disconnects the magnetic field. Under the action of a spring, the piston presses against the water with force, creating pressure. This process is constantly repeated, raising the water to the required level. These pumps have low power, but they cope well with muddy water and small stones without significant damage to their performance. They are not expensive, about 20 - 25 USD. The piston can be replaced by yourself without much difficulty;

- centrifugal. In this type of pump, the water flow is provided by an impeller connected to the motor shaft. It rotates under the action of the electromotive force generated by the magnetic field on the rotor of the electric motor. These pumps are powerful and can be used to supply water to homes and even businesses. The downside is their high sensitivity to pollution in water.Even small pebbles, 1 - 2 mm, can reduce the service life of the unit by 5 - 10 times, and a larger one can disable the pump altogether. Moreover, its repair is quite expensive. The cost of such pumps starts at $ 100.

Any of these types of units can be equipped with an automatic control system that allows the unit to be switched on even when the water tap is opened.

Helpful advice! If the water in a well or well is cloudy or there are small stones up to 2 mm in it, then it is better to choose vibrating pumps... They are less susceptible to such contaminants. In this case, you need to know that their power is 2 - 3 times lower than that of centrifugal ones.

Submersible pump for a well with automation

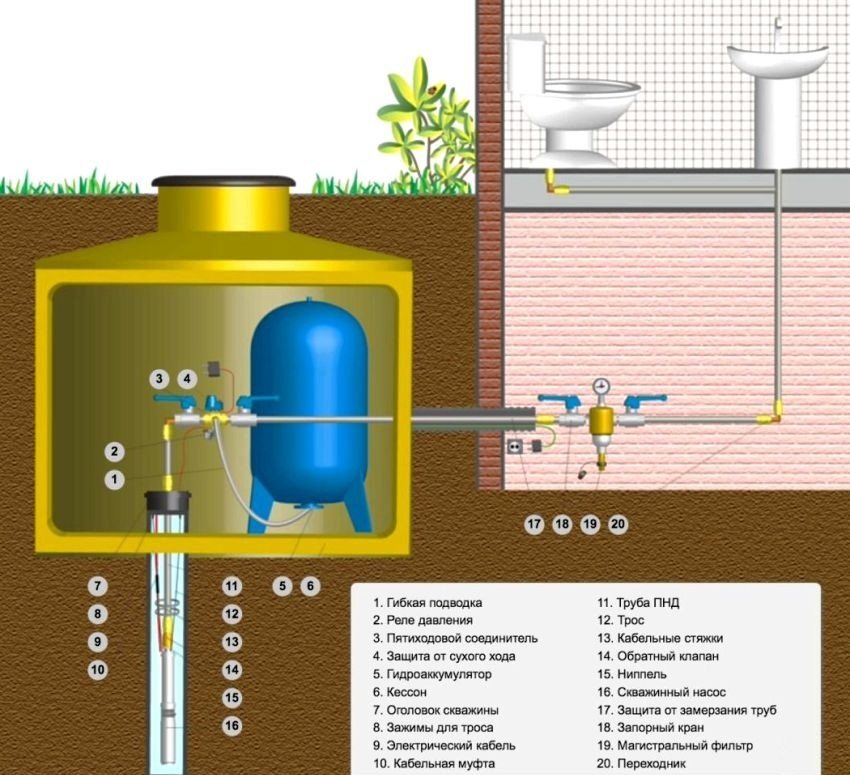

Recently, submersible pumps for wells with automation have become increasingly popular. This is no coincidence. After all, a person has always tried to make his life easier by inventing certain mechanisms. Strictly speaking, one pump and hoses are not enough to create an automatic water supply system. Additional equipment required. Such equipment includes: an electronic control unit, a hydraulic accumulator, various sensors, protection devices against overheating and low water level, filters.

Let's take a closer look at all these elements. The control unit is used to receive and process signals from various sensors. Its task is to turn on and off the pump in certain situations. The accumulator is a closed cylinder capable of withstanding high internal pressure. It contains a membrane that is connected to the sensor. It is triggered when the pressure drops below the critical one. In this case, the automation turns on the pump, which fills the cylinder with water. When the pressure rises to the required level, the pump will turn off. This mechanism is made so that the pump does not work constantly, turning on every time the tap is opened. This significantly increases the resource of the entire system and creates a stable pressure in the water supply system.

Related article:

How to install a pump to increase water pressure in an apartment. Classification of pumps for increasing the pressure in the water supply of the apartment. Selection criteria, features of self-installation.

The sensors are used to take readings from certain parameters. The water pressure sensor detects this indicator in the water supply. A dry-running sensor protects the pump from overheating. It is turned off when air enters the system, which indicates a decrease in the water level. The water level sensor ensures that the pump is turned off in case of a critical drop in the water level. It is installed on the floats of centrifugal pumps.

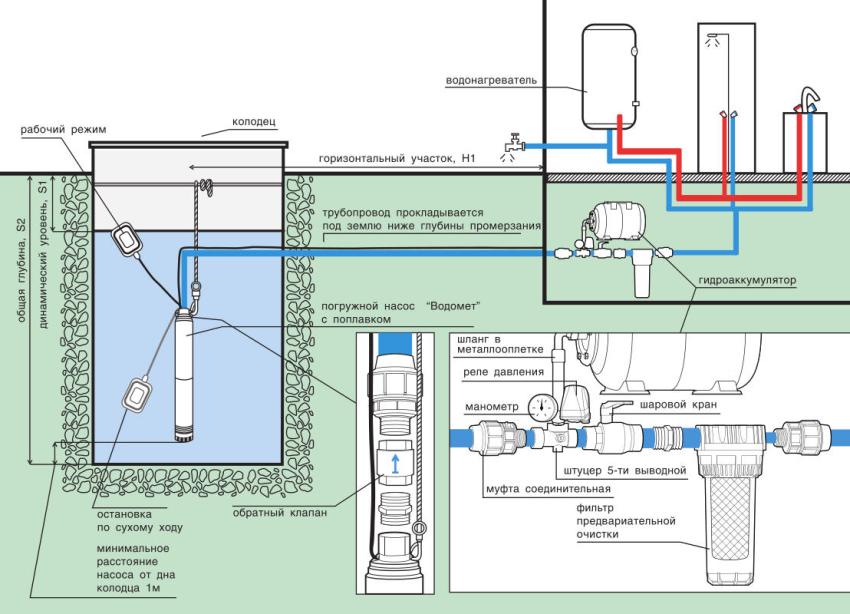

Water supply of a private house from a well using a submersible pump

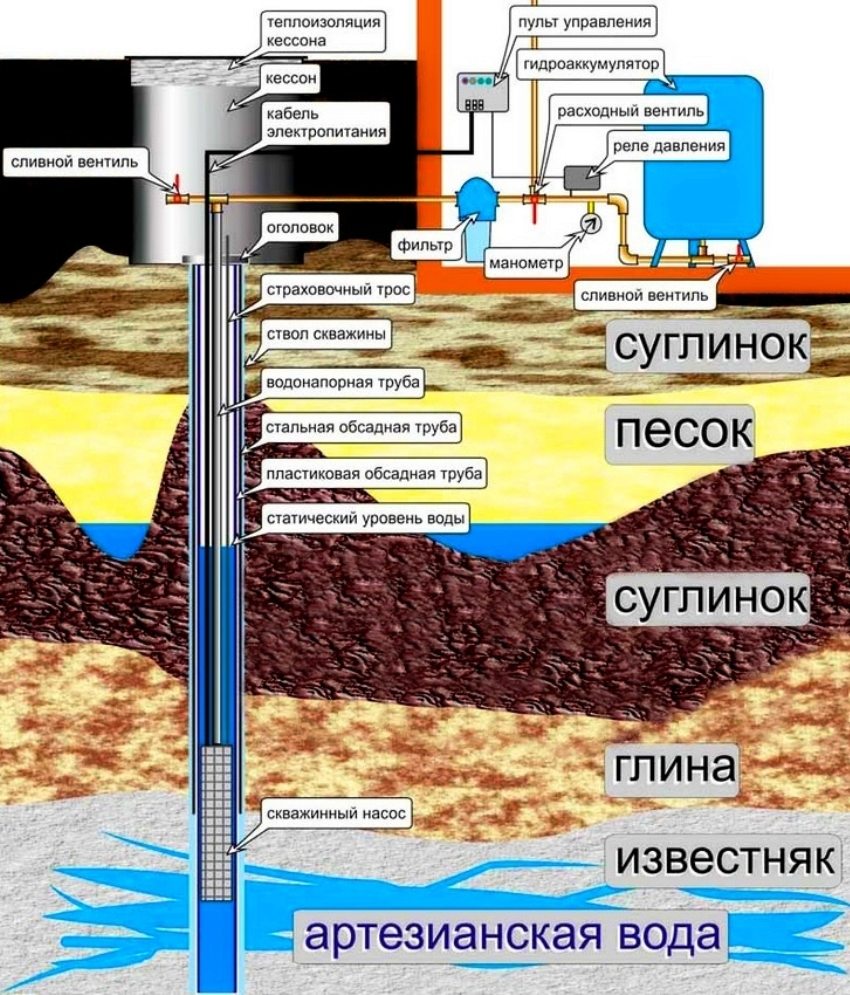

The device and operation of the automatic water supply system

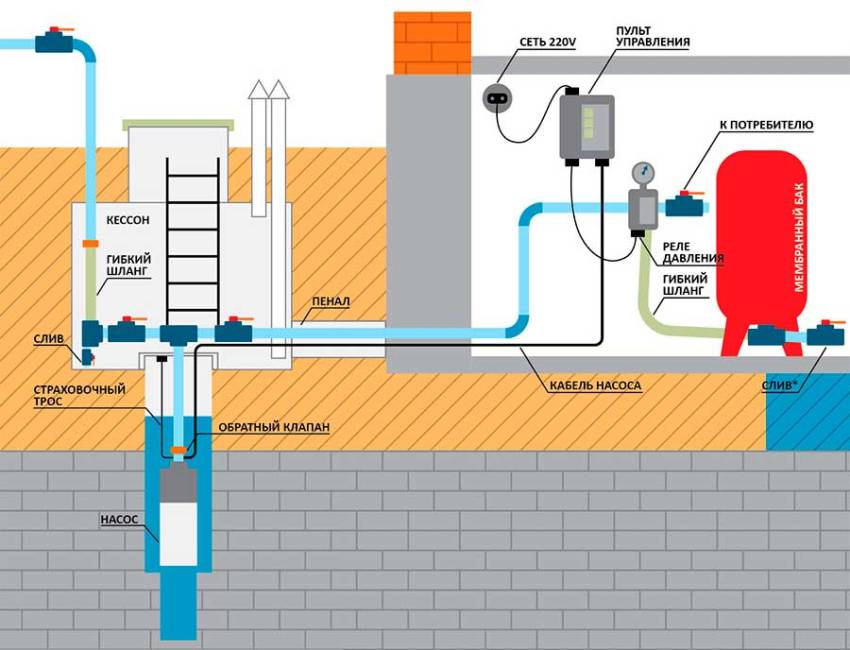

In order for submersible pumps for a well with automation to work smoothly, it is necessary to install the entire system correctly. And its structure is as follows: In a well or well a pump is located in the water column or on the float. From it comes a pipe in which there is a nipple and check valvepreventing water from flowing down. The pipe is connected at the surface to the crosspiece also through a nipple and a check valve. It contains a pressure sensor connected via a flexible hose to the control unit.

From the crosspiece, one pipe goes to the accumulator, and the other to all consuming elements: taps, toilet bowl, shower, washing machine and other household appliances. The cable from the pump is connected through the socket to the control unit. The unit itself is connected to a 220 V network through circuit breakers designed for amperage from 10 to 16 amperes. This parameter depends on the power of the equipment. The switches provide protection of the automation and the pump against overloads in the network.

Submersible pumps for a well with automation work as follows: when first turned on, the pump pumps water into the accumulator through a check valve and filters until the pressure in it reaches the maximum. The pressure sensor is triggered and gives a signal to the automation to turn off the pump. The system is now ready for use. Including a faucet or a household appliance with water consumption, we enable pressurized water to leave the accumulator. Water in it can be from 30 to 100 liters.

Helpful advice! When buying a hydraulic accumulator, it should be borne in mind that the volume of water placed in it is about 2 times less than the total volume of the device. This is because all the free space above the membrane is filled with air.

Pump piping diagram for wells with hydropneumatic automation and caisson

When most of the water has escaped, the membrane, under the action of the spring, will increase the volume of the chamber with air, which reduces the pressure. At a critically low level, the sensor will send a signal to the control unit to turn on the pump. Water filling the accumulator will increase the pressure again and the cycle can be repeated over and over again.

How to choose the right submersible pumps for a well with automation

When choosing submersible pumps for a well with automation, the decisive factor should be how high it should raise water and how far to deliver it. These parameters are reflected on the packaging and in the instructions. For shallow wells up to 20 m, any pump can be used if the water is not supplied too far. In the case when the distance to consumers is not more than 50 m, it is necessary to buy a pump with a lift height of at least 20 m. The distance from 50 to 100 m forces the use of a device with a lift height of 40 m.

Submersible operation scheme pump with automatic

The choice of pump also depends on the purity of the water. In a well cleaned of sand and small impurities, any pumps can be used, and in polluted ones only vibration pumps.

Helpful advice!If you plan to establish a permanent water supply, then it is better to purchase a pump with an upper water intake. This allows the pump not to overheat when the water level drops sharply and does not collect sand or silt. The pump will begin to "swallow air" and the automatic will turn it off.

The volume of the accumulator should be selected based on the needs of the family. With low water consumption, 50-60 liters is sufficient, and with significant water consumption, it is necessary to purchase a cylinder with a capacity of at least 100 liters.

Equipping your country house with a submersible pump for wells with automatic equipment will solve all problems with the organization of water supply. Water will be supplied automatically and without interruption to any consumer inside the house and in the garden area for watering plants.

How to install a submersible pump in a well (video)