To eliminate the likelihood of damage to electrical wiring and ensure its reliable protection from negative environmental influences when laying in the ground or walls of a building, you should worry about the presence of a special casing, which can be a HDPE pipe for the cable. You can learn about the features of the product, its varieties, selection criteria and styling options from this article.

Content

Choosing a cable brand for laying in the ground

To organize the power supply of a building, street, landscape or decorative lighting, you will need special cable products, which are most often laid in the ground. This method is the most reliable and aesthetic. The underground cable is protected from adverse external influences such as wind, frost, ultraviolet rays. The cable brand is selected based on the type of soil, its corrosiveness and further operating conditions.

Both armored cables and products without a special protective cover can be laid underground. In the first case, the wiring does not need additional protection. The cost of an armored cable for laying in the ground will be an order of magnitude higher than a product without a protective sheath. When laying unarmored cable brands, as well as crossing a power route with a road or railroad or other communications, it is necessary to use special protective structures.

It can be brickwork or concrete slabs, with the help of which special channels are created. Concrete, asbestos-cement, ceramic or steel pipes are often used. The easiest to install are protective cases made of HDPE or PVC pipes for cables.

Note! If the distance between the supporting objects is small, then open cable laying through the air (in the country, or in the local area) is also allowed.

Characteristics of armored cable for laying in the ground

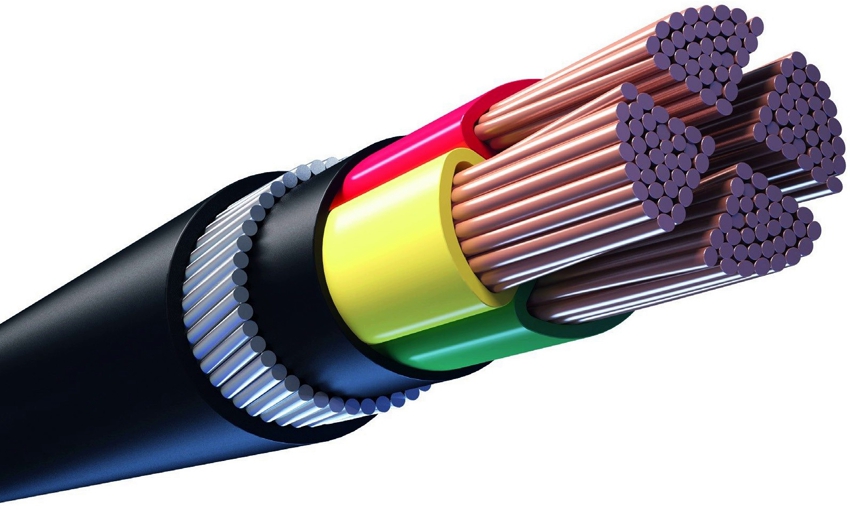

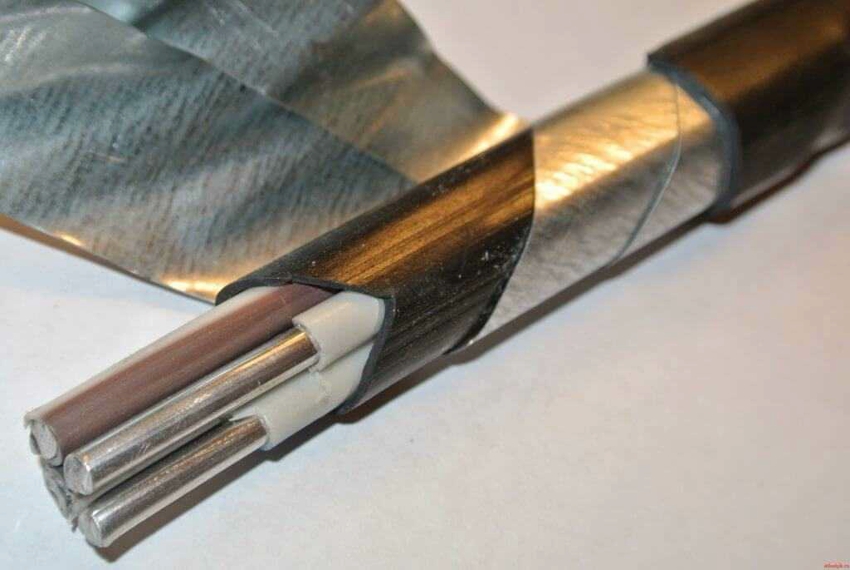

The power armored cable for laying in the ground is represented by a product, the conductors of which are located inside a metal armor sheath.It provides them with reliable protection against mechanical damage. The armored cable is available in several brands. Belonging to a certain group is evidenced by the letter abbreviation, which reflects the type of material of current-carrying conductors (TZH), armor, screens and outer shell.

The digital identifiers can be used to determine the number of TAs, their cross-section and voltage. Based on the material of the current-carrying conductor, they produce copper and aluminum armored cable (A). A layer of insulation made of polyvinyl chloride (V), polyethylene (PV) or in the form of a polymer composition (P) is applied over the core.

Based on the material and type of armor, the cable can be with wire (K) or tape (P) armor, lead (SB), or steel (B) protection. The tape casing gives the product additional mechanical strength and moisture resistance. The steel tape is applied in two layers, excluding the formation of gaps, creating a continuous armor layer. The wire braid gives the product a high degree of flexibility, which reduces the risk of cable breakage when moving the ground.

The protective hose can be made of polyethylene (Shp) or PVC (Shv). The wall thickness is in the range of 1.7-3.1 mm. The plastic hoses are fully sealed. There are no dents or cracks in their structure. The polyethylene shell is more moisture resistant. A protective hose protects the armor protection of the product from mechanical stress, moisture, chemicals contained in the soil. For example, VBbShv 5x10 is an armored cable for laying in the ground with PVC insulation, armor made of galvanized steel strips without a cushion with a polyvinyl chloride sheath, has 5 copper conductors with a cross section of 10 mm².

The choice of the type of armored cable is based on the operating conditions. When installing cable products in soils with a high content of aggressive chemicals, in places of exposure to electrocorrosion, preference should be given to products with aluminum shielding or lead armor. In places of soil subsidence or areas with strong mechanical stress, products with wire armor protection should be used. For standard operating conditions, an armored 4x10 cable for laying in the ground with an armored braid made of steel tapes will suffice.

Use of aluminum or copper armored cable

An aluminum or copper armored cable for laying in the ground is laid in a trench to a depth of no more than 70-80 cm. When installing several power lines, certain conditions must be observed. For cable products with a power of up to 10 kW, adjacent lines should be at a distance of more than 10 cm, and with a power of 20-35 kW - at least 25 cm.

Important! When installing an armored cable, it is grounded.

The armored cable is laid in the ground in the following sequence:

- preparation of the trench according to the planned route plan;

- leveling and tamping the bottom of the trench, followed by filling a layer of sand 10 cm high, which must be cleaned of any large impurities that can cause damage to the integrity of the cable sheath;

- leveling the surface of the sand cushion;

- checking the cable for integrity;

- free laying of power threads on a sand cushion without stretching, so as not to provoke the appearance of tensile forces with a possible displacement of the soil;

- checking the cable line for short circuits, which is carried out between current-carrying conductors, TC and armor;

- backfilling the cable with a layer of sand 10 cm thick, followed by its sealing;

- backfilling the trench with soil to a height of 15-20 cm;

- laying of a signal polymer tape with the inscription "Caution cable";

- final backfilling of the trench with soil with the formation of a small hill, which will exclude the formation of dips in the process of soil subsidence;

- execution of a control check for shorting current-carrying conductors with the ground.

HDPE pipe: what is it, decoding of the abbreviation

When laying an electric cable without armor in the ground or wall of a building, it is necessary to ensure its integrity and protection from mechanical and chemical damage. For this purpose, it is placed in a special tube-shaped case. Previously, concrete or metal products were often used. They significantly complicated the process of installing power lines. This is primarily due to the significant weight of the products. The metal casing is prone to corrosion. When welding individual sections of the pipe, scales formed on the inner surface, which could damage the cable.

However, progress does not stand still. And today, HDPE pipes are used for laying cables. What kind of pipe is it? Low-pressure polyethylene technical pipes are manufactured by extrusion at industrial enterprises, where the quality of the product is immediately controlled in automatic mode, and then it undergoes additional control by specialists to identify possible defects.

Two grades of polyethylene are used as raw materials: LDPE and MDPE. They contain a fire retardant in their composition, which ensures the resistance of products to fire. The structure of the material must be smooth, without cracks, swelling, sagging and other defects.

Some manufacturers produce electrical PE / HDPE pipes for cable laying from recycled materials, which reduces the cost of production. For their manufacture, polyethylene crumb is used, which is obtained after processing rubble waste with subsequent crushing of the resulting mass to a fine fraction. This feature of production does not affect the quality of technical pipes, but it has a positive impact on environmental protection.

HDPE pipe: this is a protective case for the electrical cable

Technical HDPE pipes for cables are distinguished by their strength, elasticity, frost resistance, resistance to a chemical environment, the ability to bend without loss of performance, restore linear dimensions, withstand significant mechanical and vibration loads, temperature drops. The material is environmentally friendly and does not contain harmful impurities. The pipes are also lightweight and inexpensive. Laying the cable in the ground using a plastic sheath is quick and easy. A distinctive feature of the product is their black color. There are also gray options.

Important! The presence of white streaks on the pipe indicates a high content of high-pressure polyethylene in the composition of the material, which reduces the rigidity of the products. It is not recommended to use such pipes for laying communications.

The material is a dielectric and therefore does not need to be grounded. The products have a smooth inner surface and uniform wall thickness, which contributes to easy and quick tightening of cable products into the product. Individual sections are connected to each other by welding. The service life of such a casing is at least 50 years.

The working temperature of the products is in the range from -25 to 70 ° C. The density of polyethylene is 0.949-0.953 g / cm³. The working pressure of the material is determined by the type of pipe and is 0.25 MPa for light products, 0.4 MPa for medium-light, 0.6 MPa for medium and 1 MPa for heavy pipes. The thermal expansion coefficient is 0.15-0.2 mm / mK. HDPE pipes belong to the flammability class B1 and B2.

Reasons for the demand for HDPE pipes for laying cables in the ground

HDPE pipes are used as a protective casing for power supply cables, telephony, video surveillance, computer networks, control, fire and alarm lines, which can be laid in an open, semi-hidden or hidden way. A case in the form of HDPE pipes provides reliable protection of cable products from various mechanical and chemical influences. It also excludes the possibility of electric shock in case of damage to the insulation of the network and fire during a short circuit. Thanks to a special design with a smooth inner surface, easy pulling of cables of all types into the pipe cavity is provided.

HDPE pipes for cables in the ground are lightweight, which simplifies their transportation and installation. They do not lend themselves to corrosion and the influence of other negative factors, therefore they do not need to create special conditions for storing products. Due to the elasticity of the material and the flexibility to bend, PE technical pipes can be laid along any path without the use of additional connecting elements, without losing the integrity of the structure.

Important! HDPE pipes should not be bent too much, since creases may appear on the products, which will complicate further installation.

HDPE pipes do not conduct electric current, therefore they do not require grounding and cathodic protection devices. Products are able to withstand a wide range of temperatures without loss of technical and operational qualities. They do not accumulate condensation on the surface due to their low thermal conductivity and do not emit harmful substances.

Varieties of HDPE pipes for laying cables in the ground

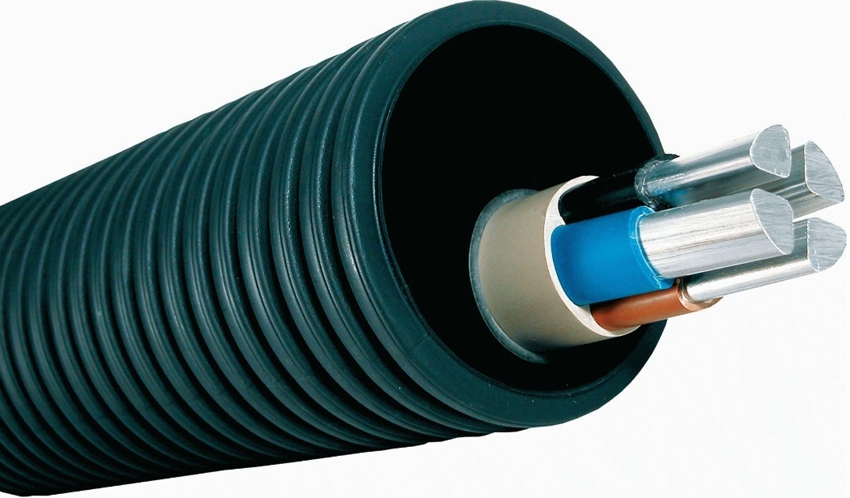

Manufacturers produce HDPE pipes in two variations: smooth and with a corrugated wall. They differ in individual technical characteristics and the possibility of laying under certain conditions.

Smooth technical HDPE cable pipes have a rigid structure and high mechanical strength. They are black in color. Such pipes are produced in two variations: one-layer reinforced and two-layer unreinforced. The first option is used for laying cable products in concrete and brick structures, floor screeds. Double-layer reinforced pipes can be used in more difficult conditions.

Important! When making transitions and turns in cable ducts made of smooth HDPE pipes, special fittings should be used.

Corrugated HDPE pipes for cables can be used both for underground and overground laying of communications. They have two-layer walls, the inner layer of which is made of LDPE and has a smooth surface, and the outer layer is made of HDPE, and has a corrugated structure. Such pipes have good flexibility, the ability to withstand significant loads, the ability to lay them at different depths and curved sections.

Types of corrugated pipes for laying cables in the ground

Corrugated pipes, based on their ability to withstand external pressure, are divided into light, medium and heavy. The first option has high elasticity and the ability to bend without violating the integrity of the product. Such pipes are used when laying electrical networks with a capacity not exceeding 1 kW. These can be television and telephone lines, household electrics. Heavy corrugated pipes are additionally equipped with a reinforcing mesh, due to which they have greater weight and less flexibility.

There are also halogen-free pipes that offer increased fire protection. They do not emit hazardous compounds into the atmosphere, even after prolonged exposure to open flames. Such products are self-extinguishing. They are most often used for laying cables inside a building.

Based on the method of laying, corrugated HDPE pipes can be with or without a cable pulling probe. The first option is more expensive. Such pipes facilitate easy and quick pulling of the cable inside the product. Probe-less options allow for more labor-intensive installation of cable products, which requires a special pulling mechanism.

Related article:

How to hide pipes in the bathroom, kitchen and other rooms: all types of communications

Recommendations and popular methods of masking heating, plumbing, sewer, gas and other communications.

HDPE pipes are painted in different colors depending on the purpose. For high-voltage lines, red products are used. Blue pipes are intended for laying telecommunications and communication lines, while black pipes are characterized by their versatility.

HDPE pipe for cable: selection criteria

The main criterion when choosing HDPE pipes for cables is the throughput of the product. The value of the inner diameter of the pipe should correspond to the total cross-sectional area of the cable products that will be laid in its inner cavity. According to GOST, a technical HDPE pipe is produced with a diameter of 16-225 mm with a wall thickness of 2-30 mm. Products with a cross section up to 90 mm are produced in coils of 100 or 200 mm. Larger diameter pipes are made in 12 m lengths.

You should know! No more than 4 cables can be placed in one HDPE pipe at the same time.

The next important criterion is the strength of the product. Pipes with a low value are used for laying cables inside a building, and with a large value, underground. You can calculate the strength indicator yourself by determining the SDR parameter. To do this, calculate the ratio of the outer diameter to the pipe wall thickness. The lower this indicator, the higher the strength characteristics of the pipe.

Each factory item is marked with a marking that determines the characteristics of the pipe, such as the name of the manufacturer, material of manufacture, SDR parameter, diameter, wall thickness, working pressure, production standard, purpose and date of manufacture.

Laying options for HDPE pipes for cable laying

The cable laying underground in the HDPE pipe can be carried out overground or underground, or inside the building.

Regardless of the way the protective casing is laid, there are certain installation rules:

- the ambient temperature must be at least -30 ° С;

- at a cable depth of more than 2 m, a concrete channel with a wall thickness of 80-100 mm is provided;

- butt joints must be sealed, for this, compression couplings, press fittings or butt welding are used;

- cables of different networks should not be located in the cavity of one channel;

- it is forbidden to bend the pipe at an acute angle, this can lead to a fracture of the product;

- the length of the section between the boxes should not be more than 25 m;

- when laying the cable in an open way outside the building, it is necessary to use a black HDPE corrugation, which is resistant to ultraviolet radiation;

- for condensate drainage, the pipe should be laid with a slope towards the broaching boxes, where moisture will collect.

Laying the cable in the HDPE pipe inside the building is carried out in the following sequence:

- marking the cable laying route;

- creating strobes in the enclosing elements of the room (if necessary);

- fastening the pipe to the building envelope. When laying along walls or on the ceiling, special holders with latches are used. Ceiling fastening by means of metal brackets;

- connection of pipeline sections;

- sealing holes. For wide and deep canals, grout is used. You can use plaster to seal small holes;

- pulling cable communications inside the channel, which should be in a free state without tension.

Outdoor cable laying in a pipe in the ground

It is best to lay the cable in the ground in a corrugation in a closed way with the arrangement of a trench in the ground. This option has more advantages over the installation of airways. The cable in the ground will be reliably protected from atmospheric precipitation, ultraviolet rays, temperature changes, wind loads and other adverse factors. In addition, it will not be available to thieves of non-ferrous metals.

Important! Before starting work, inspect the cable for the integrity of its sheath.

The process of laying the cable in the trench is carried out in the following sequence:

- performing markings for a future trench;

- excavation to the desired depth;

- tamping of the bottom of the trench with the arrangement of a sand cushion 10-15 cm thick;

- laying HDPE pipes;

- joining sections by using resistance welding. The use of fittings is not allowed, since the integrity of the route may be violated;

- pulling cable products inside the pipe without tension using a metal wire or a special nylon broach;

- backfilling the case with a layer of sand 10-20 cm thick;

- backfilling the trench with soil.

Helpful advice! To facilitate the search for an already laid track in the future, it is recommended to install signal posts above it.

Trenchless cable laying in the ground in HDPE pipe

In cramped terrain, where it is not possible to dig a trench, a trenchless method of laying a power cable in the ground is used. For this, special equipment is used, with the help of which the soil is drilled in the horizontal direction. The cost of laying a cable in the ground per running meter will be 1.5-2 times higher than the cost of trenching communications, and starts at 350 rubles.

Work begins with the drilling of a so-called "pilot" well using a special drill bit. It is mounted on a flexible bar that allows it to overcome natural obstacles in the ground. To control the trajectory of movement and correct its direction, the handpiece has a navigation apparatus and cooling holes. Simultaneously with drilling, a concrete solution is supplied, which cools the tool, strengthens the walls of the channel, protecting it from collapse, and reduces the frictional force that occurs when pulling the lash of communications.

Next, the well is expanded using a trimmer, which is installed in place of the drill head. Then the pipe is pulled, into which the cable products are preliminarily pushed. The structure is attached to a special rod of the HDD installation, with the help of which it is pulled through the well.

The use of HDPE pipes for cable products is a reliable, convenient and cheap option for laying power communications. With the right choice of products and compliance with all installation rules, it will be possible to obtain a safe and durable wiring, which will not be influenced by many external factors.