Previously, in gasified homes, the gas stove was connected directly to the gas pipeline using a steel pipe. The method was considered safe, but caused some inconvenience. The main disadvantage of the rigid installation was considered the impossibility of rearranging the slab to a convenient position in order to properly organize the working area. A modern flexible gas hose for a gas stove is considered no less safe, but allows you to install the hob wherever it is convenient.

Content

- 1 What is a gas pipe hose: the main requirements for the product

- 2 Gas hose for gas stove: main types of products

- 3 Bellows gas hose: best for gas stove

- 4 Gas hoses for gas stoves: which is better, the main rules for choosing

- 5 How much does it cost to connect a gas stove: is it possible to install it yourself

What is a gas pipe hose: the main requirements for the product

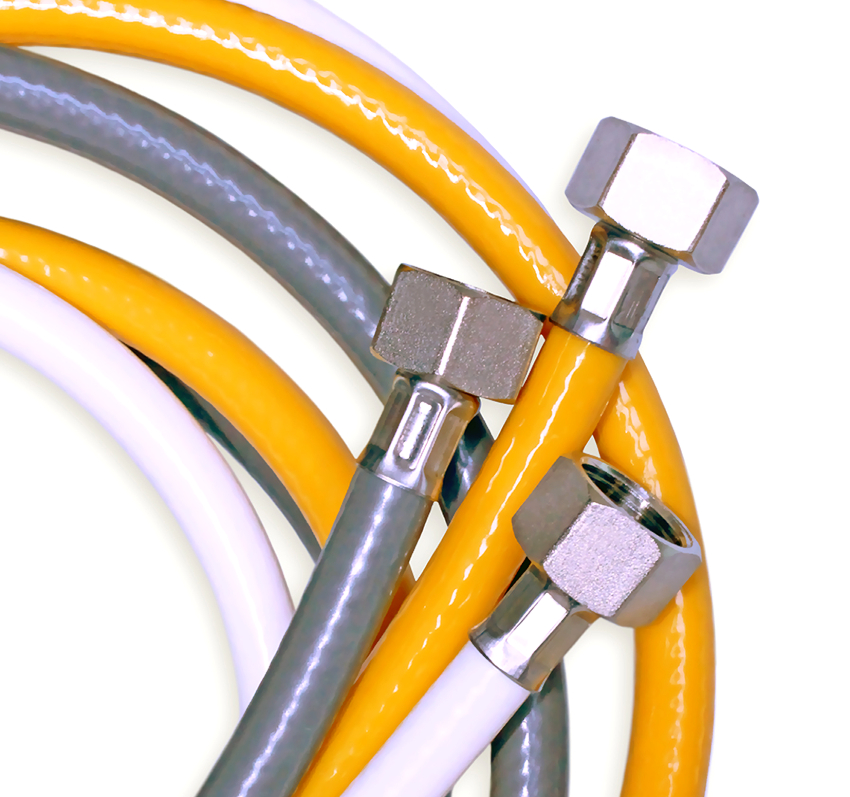

In appearance, the hose for connecting a gas stove is very similar to a water supply hose. The main difference between a gas device is the presence of yellow or white markings, which must be visible. In addition, the flexible gas stove hose is made of a special material. Another feature is the presence of a paronite gasket - a special ring that is used to seal the flange connection. It is the presence of the gasket that ensures the safety of the products.

Important! If you are wondering what kind of hose is needed for a gas stove, then the main component here is the presence of the appropriate marking and a certificate issued by Rostekhnadzor of Russia. This document confirms that the product meets the safety requirements. In addition, a passport must be attached to the hose, which indicates the date of its manufacture.

Buying a high-quality and certified product will ensure the safe use of gas, but buying a hose of dubious quality without proper documents can lead to tragedy. Other mandatory requirements for flexible gas hose for stove:

- The product must be complete, without additional couplings, extensions or connections.

- It is necessary that the flexible liner has a special coating that is resistant to hot liquids and high temperatures.

- The hose must not corrode.

- The parameters of the product must correspond to the characteristics of the gas used.

- The service life of a gas hose for a gas stove should not be less than 10 years.

It is unacceptable to connect several hoses to each other - it is better to immediately purchase a hose for a gas stove, the length of which will correspond to the distance between the gas pipe and the hob. The maximum length of a gas hose for connecting a stove according to European standards is 2 meters, although a seven-meter hose is considered the longest certified product. If you look at the corresponding Russian GOSTs, you will notice that they do not contain recommendations regarding the length of the gas hose. In any case, do not install the stove too far from the gas pipe.

The main types of hoses are: oxygen, rubber reinforced, rubber-fabric, reinforced PVC sleeves, bellows

The market now offers a wide variety of options for flexible gas connections. The materials used in production also differ in technical characteristics that affect the service life. Therefore, in order to understand what should be the hose for a gas stove in a particular situation, you need to take into account the location and features of using the hob. The main types of hoses are:

- oxygen;

- rubber reinforced;

- rubber-fabric;

- reinforced PVC sleeves;

- bellows.

Gas hose for gas stove: main types of products

Oxygen hoses were mainly used during the Soviet era due to the lack of alternatives. For the production of this type of hose, a special cord thread is used, and the additional material that is applied to protect the thread is a rubber compound.

In modern times, the oxygen hose is more often used for welding or for transporting gas mixtures such as acetylene, butane and propane. Sometimes a hose is used to connect a gas cylinder as a fuel source, which is installed far from the stove for safety. The permissible gradation of temperatures at which the product can be used is from +70 to -35 degrees Celsius. Positive aspects of using oxygen hoses:

- withstand pressure up to 20 atm .;

- easy to assemble;

- do not conduct electricity;

- differ in low cost;

- suitable for various pipe diameters.

In modern apartments, it is not recommended to use oxygen hoses to connect the stoves, because, firstly, the products are not very attractive black, and secondly, they cannot be repainted. Oily solutions will heat the hose surface and may lose integrity, resulting in gas leakage. The cost varies from 70 to 90 rubles. per meter.

The fabric-backed rubber sleeve is a simple and inexpensive option. The hose is a rubber base reinforced with a strong textile thread. Thanks to the additional components that are added to the rubber compound, the service life of the gas hose for the stove is about 5 years, which is still not enough for a quality product.

Another disadvantage of the application is the fact that after a while, cracks may appear on the surface, which can cause gas leakage. The product has a small operating temperature range, which is only from -10 to +50 ° C. The positive properties include simplicity of use, ease of installation, the ability to bend well and excellent electrical insulation.

Important! Rubber hoses for a fabric-braided gas stove must have a yellow label to distinguish them from water products. Most often recommended for connecting the hob to a gas cylinder.Experts advise replacing the hose every 2-3 years.

Other types of gas hoses for gas stoves: sizes, prices

A gas rubber hose in a metal sheath has an inner part made of polymeric materials, which is covered on top with a layer of vulcanized rubber. Outside, the hoses are braided with special steel threads, which create a so-called reinforced layer.

The main disadvantage of using hoses is considered to be the high ability of steel to transmit electricity, as well as the susceptibility of the internal polymer material to destruction, which can be overlooked due to the presence of upper layers. If the stove is not in use, it is recommended to shut off the gas hose during this time, which will increase its service life. The price for a finished product 60 cm long starts at 140 rubles.

Using this type of connection, you additionally need to mount dielectric inserts, which are installed at the junction of the hose and the gas pipe. The presence of a dielectric will protect the gas stove and the hose itself from the effects of stray current, which can cause a fire.

A gas rubber hose in a metal braid has a drawback - it is a high ability of steel to transmit electricity

The advantages of using a rubber reinforced hose:

- affordable cost;

- ease of installation;

- operation in a wide temperature range: from -35 to +50 ° С;

- wide range of lengths and diameters.

The reinforced PVC sleeve is considered more modern than the options listed above due to the fact that the material features do not allow the product to conduct electric current. In addition, polyvinyl chloride does not degrade as easily as rubber. Additional strength of the hose is provided by the presence of two layers of PVC. There is black material inside the sleeve, and the top layer is usually yellow. It is used for supplying various types of gas mixture: acetylene, propane and butane.

The PVC gas hose for a gas stove is designed for an operating pressure of up to 0.63 MPa, and the temperature at which the gas can be operated varies from -20 to +90 ° C, which is a significant advantage. Another positive aspect of using PVC products is a wide range of sizes, while the maximum length of a gas hose for a gas stove is 5 meters, and the minimum is 0.4 m. For the manufacture of fittings, galvanized steel is used, and dielectric properties are ensured due to the presence of a paronite gasket. Other product advantages:

- does not collapse on contact with a hot plate;

- affordable cost, the price per meter of the product starts from 170 rubles;

- not subject to destruction by hot oil droplets;

- suitable for use in conditions of increased loads;

- long service life: minimum - 12 years, maximum - 20 years.

Bellows gas hose: best for gas stove

If you ask a specialist what should be the hose for a gas stove, most likely he will offer to purchase a bellows version for installation. It is this type of hose that is considered the most reliable for connecting the hob to the central gas supply. In addition to gas stoves, it is used to connect columns and gas boilers used for individual heating. The bellows is an elastic corrugated casing that protects the inner layer from mechanical and other types of damage.

Great demand for bellows hoses due to the high technical characteristics and reliability of the devices. Products easily withstand high pressure, which is created by the gas flow in the pipe. Convenience of connection is ensured by two fittings designed for connection to the gas pipe and directly to the device.All hose components are manufactured from high quality stainless steel to ensure maximum service life.

Helpful advice! For a safer connection, when connecting the hose, a special gasket made of plastic or soft metal is additionally used.

The bellows gas hose is considered the most reliable for connecting the hob to the central gas supply

The price of a gas hose for a gas stove of this type is significantly higher than the cost of other product options, but the service life is at least 10 years longer than the service life of other devices. So, the minimum time during which you can safely use a bellows hose is 25 years, although some companies give a 30-year warranty. The final price is usually influenced by the manufacturer and the size of the product.

You can find out how much a gas hose for a gas stove costs (depending on the characteristics) from this table:

| Connector diameter, inch | Length, m | Price, rubles |

| 1/2 | 0,4 | from 250 |

| 0,8 | from 290 | |

| 1 | from 320 | |

| 1,5 | from 400 | |

| 3 | from 780 | |

| 4 | from 950 | |

| 5 | from 1150 | |

| 3/4 | 0,6 | from 350 |

| 1 | from 450 | |

| 2 | from 700 | |

| 2,5 | from 900 | |

| 3 | from 1050 |

The main advantages and disadvantages of using bellows hoses

Simple models of bellows hose are presented in the form of corrugated products, which are characterized by the presence of a circular cross section. If you choose a more expensive option, then in addition, a metal sleeve or a polymer coating will be present for protection. The upgraded version of the bellows hose has a built-in thermal safety valve, which automatically shuts off the gas supply when the temperature rises too high. Of course, such an option will also affect how much the sleeve costs, but the losses that can be incurred in the event of a gas leak will be much higher. Other advantages of bellows hoses:

- easy to bend and stretch;

- withstand loads up to 6 atm .;

- are operated in a wide temperature range from -50 to +200 ° С;

- are made of high quality materials that meet all GOST standards;

- meet the technical requirements of household use;

- maximum possible service life - up to 30 years from the date of installation;

- withstand the influence of electric current up to 1.5 kW;

- a wide range of hose lengths for connecting a gas stove - from 0.4 to 5 m;

- compatibility with most types of gas equipment and various fittings;

- the presence of a coating that protects the base of the hose from the effects of various household chemicals used for cleaning and disinfecting the kitchen.

Additional safety of the hose is provided by an electrically insulating polymer layer that protects not only from mechanical stress, but also from high-frequency currents generated by some household appliances, for example, a microwave oven. Due to the durability of the hose, manufacturers guarantee the integrity of the connection even in the event of natural anomalies such as an earthquake when the stability of a building is compromised.

The relative disadvantages include only the price, which is several times higher than the cost of similar products from other groups. However, the presence of a large number of positive characteristics, which include a significant service life, cover this disadvantage.

Helpful advice! When installing a stove or hob with a built-in electric ignition function, experts recommend installing an additional dielectric insert between the gas supply valve and the bellows hose for greater safety.

Gas hoses for gas stoves: which is better, the main rules for choosing

The main rule when choosing a gas hose is to purchase the product from a certified store. If the seller cannot provide a quality certificate and does not give any guarantees, it is not worth buying a product in such a place.There is usually a large selection of sizes of gas hoses for gas stoves available in retail outlets. It is important to pre-perform all measurements and buy a product of the required length, because it is not recommended to splicate two products together.

To reduce the risk of rupture of the liner, it is not recommended to choose such a length when, after installation, the hose will be in constant tension, since this can negatively affect the life of the product. The maximum length of a gas hose for a stove in an apartment should not exceed 2-2.5 meters, although there are various sizes, including 4 and 5 meters. Additionally, you need to make sure that the product not only does not stretch during installation, but also does not sag much. Only a hose that is correctly selected in length guarantees a secure connection and competent operation.

Related article:

Cylinder gas heater: prices and characteristics of the best models

Review of popular manufacturers. Varieties of devices. Determining the best models for use in various conditions.

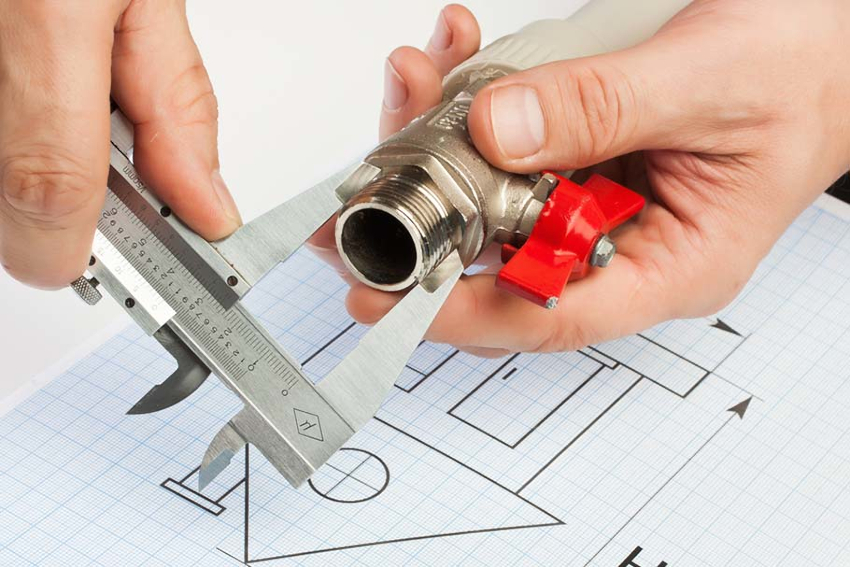

Another important indicator is the cross-sectional diameter of the hose. Here you need to know that the minimum size that ensures the normal flow of gas to the device is 1 cm. At the same time, two nuts or one union and one nut must be present at the ends of the product. It must be borne in mind that the nut is characterized by the presence of an internal thread, while the union has an external thread. The cross-sectional diameter must be selected depending on the size of the outlet on the gas appliance. For ease of installation, there is a fitting angle that simplifies the connection process.

The most budget type of hose is a rubber-fabric product. It should be noted that, having chosen this option, you need to constantly monitor its integrity - if necessary, you can use a soap solution, which makes it easy to detect a leak. If even the slightest violation of the integrity occurs, the product must be replaced. The best options for combining price and quality include reinforced PVC hoses, which are also distinguished by a long service life.

In any case, the most reliable and safe is a bellows hose, which has received official approval from state gas services for use in a domestic environment. When choosing this type of product, it is imperative to pay attention to the type and quality of the connection.

Helpful advice! You should not choose a hose where glue is used to connect the fitting to the corrugation. The best option is considered a one-piece product or a structure fastened by welding.

It is very important during the purchase to be able to distinguish an original product from a Chinese counterfeit, therefore it is recommended to choose a product in specialized stores. In order not to purchase a fake, the hose should be carefully inspected for defects, and also the passport attached to the product should be examined. You should also familiarize yourself with the price range in order not to buy a hose with a suspiciously low cost. The most important thing is to inspect the product for integrity.

How much does it cost to connect a gas stove: is it possible to install it yourself

When installing the stove, you need to choose the right hose, taking into account the features of the gas valve. Depending on this, the connection can be either a nut-union or a nut-nut. Some gas stoves are distinguished by the presence of several inlet pipes, although only one is used - in this situation, the excess outlet is closed with a plug. The price of connecting a gas stove in Moscow from certified craftsmen starts from 1300 rubles for a stove and from 1500 rubles for a built-in hob.

If you previously did not have experience connecting the stove to a gas pipe, it is better to entrust this business to professionals. In any case, it is important to adhere to the basic safety rules:

- The hose must be clearly visible so that damage can be monitored. It must not be covered with furniture or household appliances.

- Only the location of a wire that provides illumination or electric ignition of a gas appliance is permissible near the product.

- Do not paint the surface of the gas hose.

- Parts made of metal must be protected from condensation and moisture, which can lead to oxidation of the product.

- Do not connect hoses made of different materials to each other.

- After installation, a slight slack is permissible, but there should be no tension.

- Do not bend or twist the device.

- Tighten the connections tightly, but without excessive force, so as not to break the threads.

- It is better not to use the hose for an extended period - it must be replaced after the time indicated in the passport.

When installing the stove, you need to choose the right hose, taking into account the features of the gas valve

Helpful advice! It is recommended to periodically apply soapy water to the hose and joints to prevent damage and possible gas leakage.

The choice of a gas hose for connecting a stove or a column is a serious task, on the competent implementation of which the safety of not only the family, but also the entire residential building depends. The service life of the product depends on how high-quality the hose is chosen, and on the correct installation. It is very important to pay attention to the markings in order not to accidentally use the water supply hose to connect the gas. In the absence of experience, it is better to entrust the selection and installation to professionals.