This article discusses in detail the features of products such as PVC pipes for sewage: the sizes and prices of plastic elements and additional components used to install a drainage system. In the text, you can find the classification of pipes, their advantages and disadvantages, as well as an overview of the catalogs offered by hardware stores. This information can be used to select and purchase PVC products in order to perform a sewer installation.

Content

- 1 Features of pipes for PVC sewage: types of components, photos of products

- 2 PVC pipes for sewage: sizes and prices of products

- 3 Recommendations for installing sewage from plastic pipes with your own hands

- 3.1 How to make the transition from a cast iron pipe to a plastic sewer: dismantling the old system

- 3.2 Installation instructions for sewage from plastic pipes

- 3.3 Installation of sound insulation when replacing the cast-iron sewage system with a plastic system

- 3.4 Features of professional sewerage installation: the price for the work of specialists

Features of pipes for PVC sewage: types of components, photos of products

Sewerage is constructed on the basis of pipes, which are an integral part of the system. During operation, these elements are subjected to static and dynamic loads, therefore, the choice of products should be approached thoroughly and attention should be paid to technical characteristics.

Polyvinyl chloride products are widely used for the arrangement of both internal and external sewage systems. Among other polymer products, they are considered the most popular and in demand. These cylindrical plastic products are made on the basis of polyvinyl chloride thermoplastic. This material has one advantageous property due to which PVC pipes acquire improved characteristics. The fact is that PVC thermoplastic retains its shape well after temperature treatment and extrusion.

According to GOST 51613-2000 non-pressure PVC pipes for sewerage are tested for impact resistance according to the Charpy system. The maximum allowable number of elements that are subject to destruction should not exceed 10%.

Note! A slight change in the length of the elements after heating is allowed, but not more than 5%.

GOST also defines the standard dimensions of plastic pipes for sewage, as well as maximum deviations from the parameters that are acceptable in quality products. Polyvinyl chloride contains two components - stabilized chlorine and ethylene. In order to improve performance, manufacturers add various additives to thermoplastic mixtures. As a result, under the influence of high pressure, a composite joint with a high safety factor is obtained.

PVC pipes for sewage have a very high margin of safety and are not affected by aggressive environments

Why is it profitable to buy PVC pipes for sewage

Polymer products have many advantages. Manufacturers have endowed plastic pipes with a low weight, while maintaining a fairly high level of strength. The cost is affordable for most buyers, so consumers prefer this type of product.

The most important benefits also include beneficial performance. The inner walls of polymer pipes have a smooth surface with a slight presence of longitudinal stripes and waviness, so the likelihood of blockages caused by the accumulation of faecal fractions or growths is extremely low. Plastic is not subject to corrosion and is resistant to aggressive media.

For the construction of a pressure sewage system, PVC pipes are ideal. Moreover, the installation of the system can be done with your own hands. This does not require the use of special equipment. A wide variety of sizes and mounting elements are available for sale, which greatly simplifies the design and installation of piping.

Frost resistance is inherent in products intended for laying an external sewage system. The effective service life of pipes made on the basis of polymers exceeds 50 years. If you strictly follow the requirements of the installation technology, the sewer line will not be displaced. The docking nodes often diverge when the groundwater level changes. But if there were no violations during the installation process, even in such conditions, the system of polymer pipes remains sealed.

To avoid leakage, it is necessary to carry out the installation of sewer pipes strictly in accordance with technical requirements

Important! Under the influence of ultraviolet radiation, the performance of pipes is reduced. Therefore, it is not recommended to store the products in places where they will be exposed to direct sunlight.

Types of plumbing pipes and PVC adapters for sewage

The range of plastic products is very wide, thanks to which consumers can buy plastic pipes for sewerage of any modifications and purposes. Taking into account the purpose and operating conditions, three categories of elements for the construction of the highway can be distinguished.

All of them are in full compliance with the main standard sizes. Products with lightweight construction (SN-2) are used for laying sewage in the area of the pedestrian sidewalk. The scope of their application extends to recreation areas with green spaces, as well as areas that are not subject to traffic loads.

Pipes with averaged parameters (SN-4) are laid in areas where there is little traffic. Heavy-duty pipes (SN-8) are provided especially for industrial areas. These products are suitable for organizing the sewerage system in places with high traffic.

In addition to straight pipes for the construction of sewerage, connecting elements are used. With their help, you can organize turns of the line (fittings equipped with a rubber seal).Also, on their basis, connections between the toilet bowl and the sewer from plastic pipes or joints between other elements are formed.

The following types of adapters are on sale:

- couplings for network repair service;

- reductions connecting elements with differences in section size;

- tees and crosses for the formation of a wiring of several pipes;

- rotary bends;

- expansion joints for repair work.

In addition, in stores you can buy plastic sewer hatches to carry out an audit. These elements are also used to service the system when blockages occur.

PVC pipes for sewage: sizes and prices of products

The most demanded diameter of PVC sewer pipes is 110 mm. Such products are lightweight and do not cause difficulties during installation. Pipes intended for the construction of an outdoor system can have a two-, one- and three-layer structure. The outer layer is made of non-plasticized PVC. In three-layer products, the inner layers are made of foam material having a porous structure. It is a recycled product.

The connection of the pipe walls is carried out simultaneously using the "hot" technology. The result is a cylindrical product with a monolithic structure. Due to the cavities that are formed between the walls, it is possible to reduce the weight of the pipe.

Classification of products according to the class of ring stiffness:

- L - light products that are laid to a depth of 80-200 cm.

- N - pipes of medium rigidity, intended for installation at a depth of 2-6 m.

- S - rigid products with a large wall thickness that can withstand loads at a depth of 8 m.

Useful advice! For the organization of the external system, it is recommended to use double-layer pipes with a corrugated structure. Due to the presence of stiffening ribs on the outside, the strength of the products increases.

Ring stiffness is marked with the abbreviation SN. The technical parameters of pressure pipes and elements for systems where wastewater is transported by gravity are completely different. In each of the cases, the sewage system is subjected to different loads: pressure pressure or the influence of gravity. For this reason, the prices of plastic sewer pipes of a pressure type are much higher than that of elements for gravity systems.

The pressure pipes are available in three variations to cope with pressure effects of 10, 6 and 12.5 kg per cm².

Sizes and prices of plastic pipes for sewage: external system

For the construction of external and internal sewers, products of different sections are used.

Typical dimensions of the diameter of plastic pipes for sewage:

- 110 mm - the minimum cross-sectional size for pipes for outdoor use, used for drainage in summer cottages;

- 315 mm - products with this cross-section are intended for the construction of a common sewage system serving several houses;

- 630 mm - pipes with a maximum cross-sectional size for the construction of a highway capable of serving a small village.

In addition, to work with an external system, you will need to buy a hose for pumping out the sewage system, made of polyvinyl chloride.

Fecal hose prices:

| Manufacturer | price, rub. |

| Pedrollo TR (10 m) | 1650 |

| Omnigena (100 m) | 2500 |

| Aqua Planet Group (25 m) | 2870 |

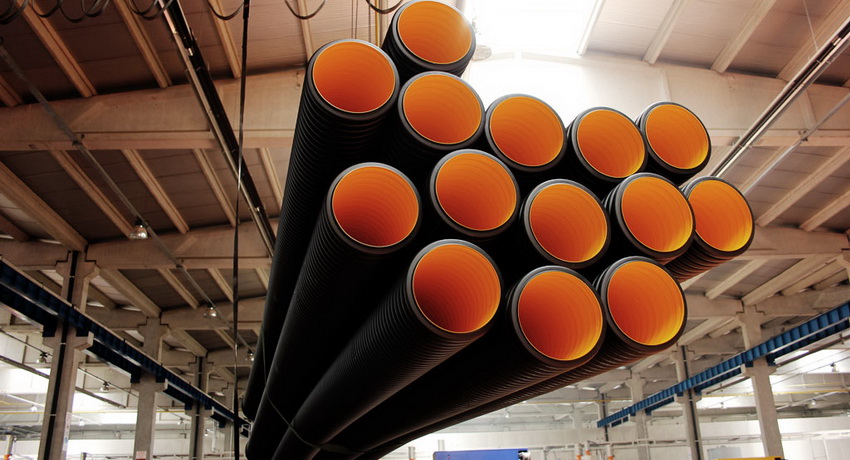

Pipes for outdoor sewerage are made in orange, so they cannot be confused with other product options. Cylindrical elements can have different lengths. The most popular segments are 0.5, 1 and 2 m. There are other variations, for example, 3 m and 6 m. Some manufacturers have an extended range of sizes. They offer individual elements 12 cm in length.

Average prices for PVC products of class SN 4 for outdoor sewerage:

| Diameter, mm | Product length, mm | price, rub. |

| 110 | 560 | 95 |

| 1000 | 162 | |

| 2000 | 310 | |

| 3000 | 455 | |

| 4000 | 594 | |

| 6060 | 896 | |

| 125 | 572 | 116 |

| 1072 | 204 | |

| 2072 | 403 | |

| 3072 | 553 | |

| 4072 | 805 | |

| 6072 | 1050 | |

| 160 | 580 | 182 |

| 1000 | 294 | |

| 2000 | 565 | |

| 3000 | 837 | |

| 4000 | 1098 | |

| 6080 | 1662 | |

| 200 | 606 | 230 |

| 1200 | 527 | |

| 2000 | 862 | |

| 3000 | 1274 | |

| 4000 | 1673 | |

| 6090 | 2530 | |

| 315 | 1200 | 1225 |

| 2000 | 1973 | |

| 3000 | 2887 | |

| 4000 | 3917 | |

| 6140 | 5752 |

Price of PVC sewer pipes for internal sewerage

Pipes for the arrangement of the internal bend system are gray. They have a low price, since these products are characterized by a light class of rigidity and are completely unsuitable for outdoor work. The most popular PVC pipes for sewage are 50 mm in diameter. Although there are other cross-section sizes on sale - 32, 40 and 110 mm.

The inner walls of the gray pipes are smooth. The elements are connected to each other using the "socket" technology. The length varies from 25 cm to 3 m, although there are also non-standard sizes.

Note! The branch connecting the plumbing to the vertical pipe must match the diameter of the riser. The use of a smaller section is not allowed.

For the construction of a drainage system in a bathroom, it is recommended to use pipes with a cross section of 75 mm. They are suitable for connecting a shower stall, bidet and washbasin to a public drain. They are characterized by a fairly high throughput.

For domestic drains, products with a diameter of 50 mm will be sufficient. They are lightweight, flexible and resistant to high temperatures (hot water) and chemicals (in case of chemical cleaning of the system). To connect the toilet, it is better to take products with a cross-sectional area of 100-110 mm. They will withstand strong pressure, since they are especially resistant.

Sizes and prices of PVC pipes for indoor plumbing:

| Diameter, mm | Product length, mm | price, rub. |

| 32 | 250 | 30 |

| 500 | 45 | |

| 1000 | 60 | |

| 2000 | 105 | |

| 40 | 250 | 32 |

| 500 | 47 | |

| 1000 | 63 | |

| 2000 | 108 | |

| 50 | 250 | 35 |

| 500 | 48 | |

| 750 | 55 | |

| 1000 | 65 | |

| 1500 | 86 | |

| 2000 | 113 | |

| 3000 | 150 | |

| 110 | 250 | 90 |

| 500 | 120 | |

| 1000 | 160 | |

| 2000 | 240 | |

| 3000 | 450 |

Catalog of fittings for PVC drainage and prices for products

The fittings are used in systems where the drain temperature does not exceed 80ºC. The products also withstand short-term disposal of waste liquids up to 95ºC.

In this case, sinks means:

- Dirty toilet water.

- Waste liquid from the shower stall and sink.

- Chemical compositions with a pH range of 2-12.

For internal sewerage, the following details are used:

- couplings (with emphasis, full bore for repair);

- reduction;

- revisions with a cover;

- tees (with an angle of 90, 67, 45º);

- two-plane crosses (with an angle of 90 and 45º);

- stubs;

- single-plane crosses (with an angle of 90 and 45º);

- bends (with an angle of 45, 30 and 90º);

- compensation pipes.

A set of fittings for an external sewage system looks almost the same, although it does not do without certain differences.

For external sewage, the following parts are used:

- standard bends (with an angle of 30, 15, 45, 90 and 67º);

- double-socket bends equipped with rubber rings on both sides;

- standard couplings;

- standard and three-socket tees (the last option with a 90 ° angle);

- single-plane crosses (90º);

- check valvesmounted horizontally with a slope of 2 cm per 1 m length;

- two-knee siphons.

Average prices for connecting elements for an outdoor system:

| Item type | Diameter, mm | Angle, º | price, rub. |

| Diversion | 110 | 15 | 125 |

| 30 | 125 | ||

| 45 | 130 | ||

| 60 | 150 | ||

| 87 | 130 | ||

| 125 | 45 | 135 | |

| 87 | 135 | ||

| 160 | 15 | 242 | |

| 30 | 264 | ||

| 45 | 295 | ||

| 60 | 315 | ||

| 87 | 367 | ||

| Tee | 110/110 | 45 | 235 |

| 125/110 | 45 | 275 | |

| 125/125 | 45 | 345 | |

| 125/110 | 87 | 355 | |

| 125/125 | 87 | 360 | |

| 160/110 | 45 | 430 | |

| 160/160 | 45 | 590 | |

| 160/110 | 87 | 400 | |

| 160/160 | 87 | 480 | |

| Revision | 110 | — | 480 |

| 125 | — | 500 | |

| 160 | — | 595 | |

| Plug | 110 | — | 48 |

| 125 | — | 100 | |

| 160 | — | 135 | |

| Coupling | 110 | — | 107 |

| 125 | — | 110 | |

| 160 | — | 255 | |

| Check valve | 110 | — | 1940 |

| 125 | — | 2500 | |

| 160 | — | 3585 |

Recommendations for installing sewage from plastic pipes with your own hands

The sewage system in older buildings was mainly made of cast iron. Despite the practicality of this material, sooner or later it will need to be replaced. For the construction of modern risers, more durable and lighter materials are used.

Useful advice! When replacing the piping, it is possible to organize ventilation that was not available in the old type systems. Thus, it will be possible to eliminate unpleasant sewer odors that can penetrate the room.

Experts even recommend refusing to use galvanized and steel pipes, the term of which is no more than 10 years, and give preference to polyvinyl chloride or polypropylene products. The shelf life of polymer elements is 30-50 years.

To dismantle the old sewage system, you will need the following tools:

- large screwdrivers to get small parts out of the system;

- grinders with a disc for metal;

- plastic wrap to cover the pipe opening at the cut;

- nail puller and chisels;

- personal protective equipment (glasses, gloves, apron);

- hammer and puncher;

- scrap and grinder.

How to make the transition from a cast iron pipe to a plastic sewer: dismantling the old system

First you need to mark the necessary indents. The first mark is placed at a distance of 10 cm from the ceiling level, and the second at a distance of 80 cm from the tee. In the marked areas, it is necessary to make cuts with the help of a grinder, half the pipe section deep. Attach a chisel to the upper cut and hit with a hammer.

A similar procedure must be performed from below. To hit with a hammer, force must be applied so that the cast iron pipe breaks, and its middle part can be removed.

The section of pipe coming from the ceiling must be closed with plastic wrap.

The lower part of the system consists of a tee and other connecting elements. To dismantle it, you will need a crowbar or nail puller. These tools are necessary in order to loosen the fixation zones. When done, you can delete fitting... In some cases, you cannot do without using a puncher. It allows you to remove the cement that holds the attachments.

It is allowed to use a screwdriver or chisel, with which you can chip off the cement. After that, the tee is removed. If this procedure fails, you can use a grinder equipped with a disc designed for working with metal surfaces to cut the fitting. In this case, you should step back from the socket by about 3 cm. Having dismantled the connections, carefully clean the areas of their placement from dirt, and then treat the surface with a grinder.

Useful advice! Before starting work, it is imperative to notify the neighbors, since during the replacement of the pipeline, you cannot use the toilet and bathroom. Otherwise, water from the upper floors will pour into the room and flood the neighbors below. For the same reason, all work must be carried out as quickly as possible.

Installation instructions for sewage from plastic pipes

To complete the installation work, you will need the following tools and materials:

- pipes with a cross-sectional area of 110 mm;

- outlet tee;

- rubber cuffs designed to seal and fix fasteners between the PVC pipe and the scraps of the cast iron system;

- a branch pipe that provides a transition from a cast iron pipe to a plastic one and vice versa;

- pipe fittings;

- soap to be used as a lubricant to facilitate mounting the mounts;

- vertical building level.

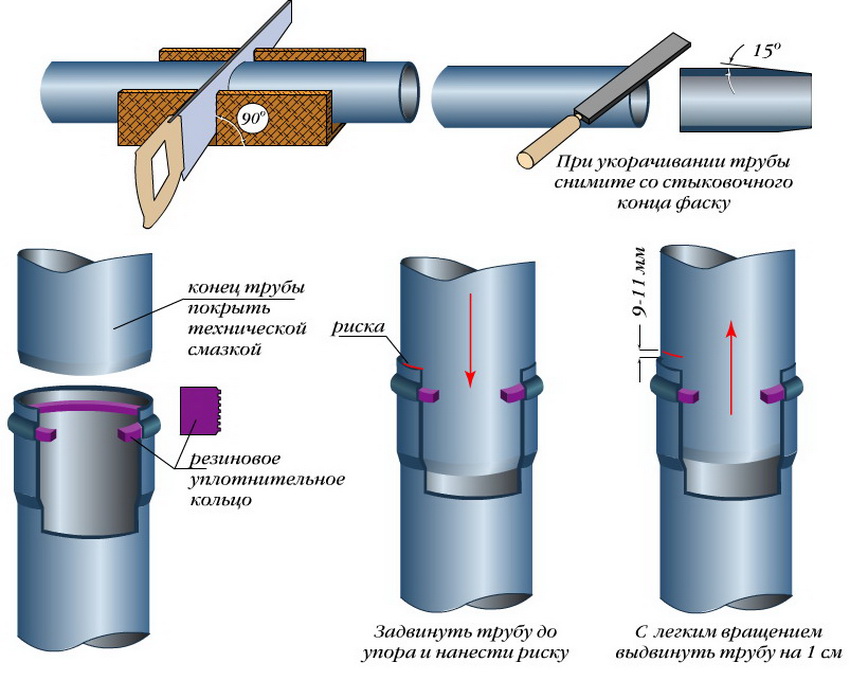

The process of installing plastic pipes is carried out in the same way, only in reverse order. Rubber sealing collars must be inserted into the cuts of the cast iron pipes. The adapter is installed from above, from below you need to install the tee. The fixation of all elements must be as tight as possible in order to ensure the tightness of the sewer system. If the tee in the joint runs freely, it can be sealed with linen or silicone based sealant.

Related article:

Drainage pipes for groundwater disposal: complete product classification

Drainage of groundwater from a suburban area: common types of products, their characteristics, prices and features of use in drainage systems.

It is recommended to use hose clamps to ensure a secure fit of the plastic riser. With a standard ceiling height, three fixings are sufficient: top, bottom and middle. If the ceilings in the room are high, more clamps will be required for fixing.

Before direct installation, the plastic system is pre-assembled. A branch pipe is installed in the tee, providing a connection between the cast iron element and the plastic. Each mount is pre-treated with silicone sealant.

Note! Wait until the sealant is completely dry before turning on the water and testing the system for leaks. The product packaging contains the necessary information.

Installation of sound insulation when replacing the cast-iron sewage system with a plastic system

Many apartment owners note the excessive noise of the plastic sewer system. To dampen the level of vibration impact, you can purchase special pipes that dampen noise. Some firms are engaged in the production and installation of such systems. For the manufacture of such products, plastic and additives in the form of mineral powder are used. The result is a material similar in characteristics to cast iron, but its cost is high, and the service life is much shorter than that of PVC pipes and is 20 years.

For this reason, ordinary pipes are most often used, and after their installation, the system is isolated from sounds and noises. The blocking at the walls is carried out through the use of damper clamps. For the floors, polyurethane foam boards are used. To get rid of the unpleasant gurgling in the pipes themselves, you can use foam or polyurethane foam. With the help of these materials, the wiring of the system and the riser are wrapped.

It is not recommended to use polyethylene foam for these purposes. Despite the fact that this material has excellent sound insulating properties, its service life is short. In addition, there are frequent cases of souring of polyethylene, and its surface becomes sticky after the first year of use.

Features of professional sewerage installation: the price for the work of specialists

If you are not confident in your own strengths and skills, you can use the services of professional firms that specialize in the dismantling and installation of sewer systems.

Average prices for professional plumbing work:

| Name of service | price, rub. |

| Installation of sewage from PVC pipes (Ф32) | 210 (lm) |

| Installation of sewage from PVC pipes (F50) | 260 (m.p.) |

| Installation of sewage from PVC pipes (Ф100) | 320 (m.p.) |

| Organization of an installation site for plumbing equipment | 350 (pcs.) |

| Arrangement of output for technical needs | 800 (pcs.) |

| Installation of a toilet bowl with a floor type of placement | 1550 |

| Installation of a bidet with a floor-standing type of placement | 1550 |

| Installation of a wall-hung toilet | 2100 |

| Wall-hung bidet installation | 2100 |

| Replacement of PVC riser | 2250 (floor) |

| Installation of PVC pipes in rooms with a ceiling height of more than 2 m | + 10% of the cost of work per lm |

Sewer systems based on PVC pipes are today considered the most practical, convenient and affordable among other options. Regardless of whether the installation is done by professional hands or by the owner's own efforts, the result fully justifies the costs. Provided that all the requirements of the installation technology are maintained, such a system can serve for more than half a century.