The storm sewage system is designed to drain water from the local area that enters there naturally with natural precipitation (rain and snow). At the heart of any drainage system are special containers through which water flows. Storm drain trays vary in size and material, they are used to install one complete drainage structure in a suburban area.

Content

- 1 The device and types of storm sewers

- 2 Calculation of the storm drainage system

- 3 Plastic, metal, composite and reinforced concrete drainage trays: types, sizes and features

- 4 Stormwater drainage trays: selection criteria

- 5 Installation of concrete, metal or plastic drainage trays with a grid: the cost of work

- 6 Care of storm sewers from trays

- 7 DIY trays for storm sewers

The device and types of storm sewers

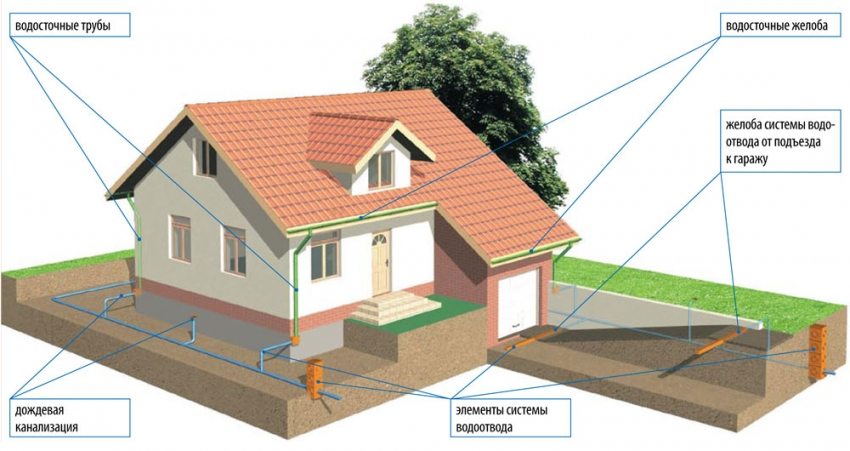

The sediment drainage system includes a large number of components, each of which is designed to fulfill specific purposes:

- storm water inlets - pallets, funnels, linear trays;

- elements serving to move water to storm wells or other destinations - pipes, gutters, plastic or concrete trays for storm sewers;

- inspection wells for monitoring the entire system;

- special filters that retain various debris that enter the system with water and protect it from contamination.

All these elements are quite simply combined into a single system, the type of which depends on the characteristics of the territory or personal preferences. Storm sewers can be laid at a shallow depth in the ground, or mounted on the surface.

According to the method of collecting water, storm sewers can be point or linear. In the first case storm water inlet mounted underground with an outlet under the drain. The hole through which water enters the system must be protected by a special grate so that various debris does not fall into it. Linear sewerage is mounted on the surface and is a shallow trench created for the installation of drainage trays. In the second case, grids for drainage trays are laid along the entire length of the system and perform the same protective function as in a point sewer.

The point system is good when rain or melt water needs to be removed only from the roof surface.If you need an effective drainage from a large area, then it makes sense to design a linear system, since it is capable of covering a large area, and its installation is relatively simple.

Note! When arranging a storm sewer of any type, it should be borne in mind that the trays must be laid with a slope in the direction to which the drainage is planned.

Calculation of the storm drainage system

The device of a storm sewer from trays with your own hands is a relatively simple matter, but for its implementation you will need to make a number of calculations. These calculations will allow not only to design the system more accurately, but also to save finances by purchasing exactly the number of elements that will be required for the most efficient drainage.

To calculate the storm sewer, the following data will be required:

- the frequency of precipitation in your area, as well as the thickness of the snow cover. The last parameter is necessary for calculating the removal of melt water;

- average rainfall in the region. This indicator is expressed in millimeters and corresponds to the thickness of the precipitated water layer;

- drainage area. In the case of a linear sewage system, this will be the total area of the territory from which it is planned to drain water, and with a point sewage - the area of the roof;

- location of existing underground utilities on the site;

- full characterization of soils on the territory.

You can choose and buy a drainage tray of the required type only if all these parameters are taken into account when designing the system, otherwise the storm sewer will not be as efficient as possible.

The amount of water that the system must remove is calculated by the product of three factors: the numerical expression of the intensity of precipitation, the surface area (from which water is required to be removed) and the correction factor. Precipitation data can be obtained from the local meteorological station. The last value is constant and depends on the type of area coverage:

- 0.4 - the area covered with rubble;

- 0.85 - concrete or reinforced concrete coating;

- 0.95 - paved paths and areas;

- 1 - roofs.

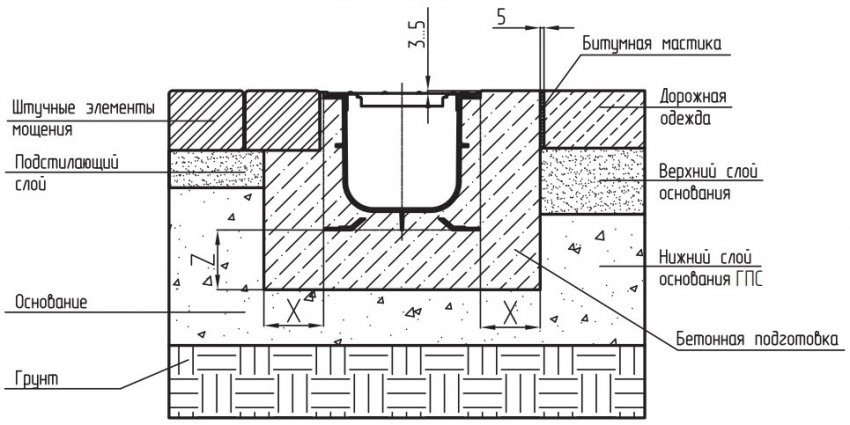

The installation depth of the drainage channels depends on the size of the product and the type of system planned. In this case, it is necessary to take into account the presence of a drainage system on the territory: storm sewers should always be laid above it. The average installation depth of the drain is usually 0.3 m for trays with a diameter not exceeding 50 cm, and 0.7 m for larger trays.

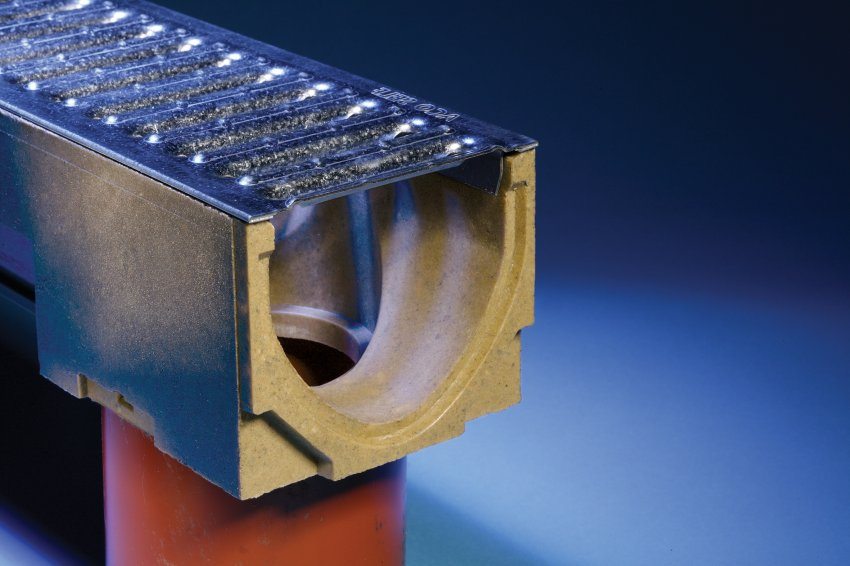

Plastic, metal, composite and reinforced concrete drainage trays: types, sizes and features

The main element of any type of stormwater drainage system are special trays through which water is removed from the territory. They are made of various materials and differ in a number of characteristics, the main of which is the maximum permissible load. According to this parameter, trays are classified into the following classes:

- A15 - are used for the installation of a storm sewer system on personal plots, sports grounds, in parks and pedestrian areas. The maximum load is 1.5 t;

- В125 - trays of this type withstand a load of 12.5 tons and can be used to drain water from car parks, in garage cooperatives, as well as on roads for passenger cars;

- C250 - used at gas stations, car washes and other areas of the car service. Withstand a load of 25 tons;

- D400 - This type of storm drain is widely used in small industrial plants, transport terminals, industrial areas and on highways with high traffic levels. The maximum load is 40 t;

- E600 - mounted in warehouses, large enterprises, berths, logistics centers. Load - 60 t;

- The F900 is the most resistant to physical activity type, capable of withstanding up to 90 tons. It is used to drain water from airfields, military bases and places where various super-heavy equipment is used.

The second significant parameter by which trays differ is their throughput. It depends on the hydraulic section of the structure, which is determined by its height and width.

As for materials, the following options are used for the production of trays:

- Concrete or reinforced concrete.

- Plastic.

- Various metals and alloys such as cast iron.

- Composite materials.

Concrete and reinforced concrete drainage trays

The use of concrete or reinforced concrete drainage trays makes sense when it is planned to drain water from an area that is constantly exposed to heavy loads. It can be a busy motorway, car park and many other places. The price of concrete drainage trays is slightly higher than plastic ones, but lower than composite ones, and their performance characteristics are at a high level.

In addition to the ability to withstand heavy loads, concrete products are characterized by increased resistance to various adverse influences and weather conditions. They do not rust, they are resistant to constant exposure to chemicals, such as fuel. In addition, the simplicity of the design leads to a long service life. As a rule, concrete trays are made with the expectation of removing a large amount of water, therefore systems based on them have a high throughput.

The disadvantages of concrete and reinforced concrete structures can be attributed to their large weight, which significantly complicates the installation of storm sewers on their own, this requires the use of specialized equipment.

Note! All options for drainage trays of concrete products have special grooves, which are combined during installation, which eliminates the possibility of leakage. This means that the concrete trays can be simply connected to each other without the need for additional sealing.

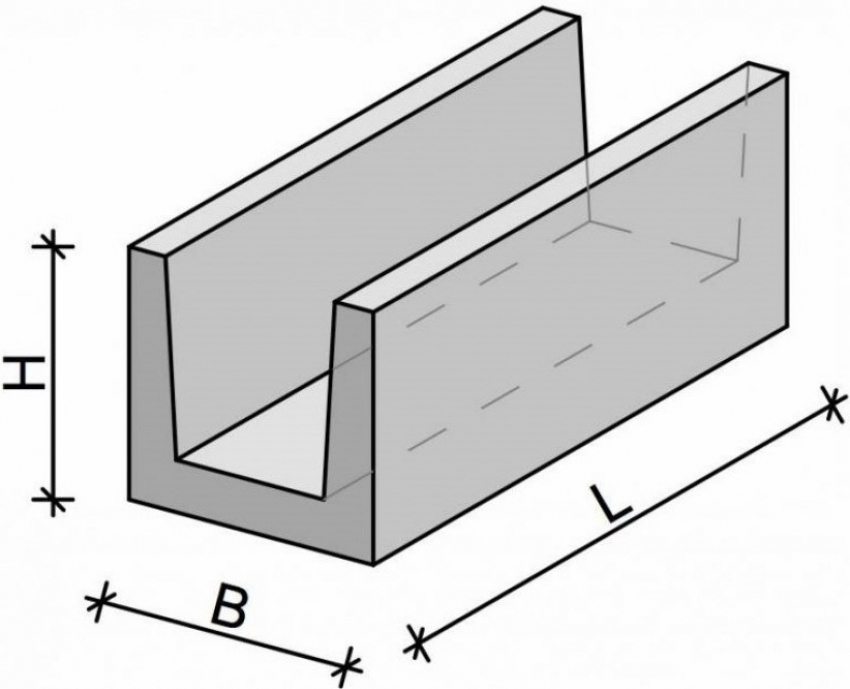

According to GOST, concrete drainage trays can be produced with different parameters. Thus, the width of the hydraulic section can vary from 100 to 500 mm, the height - from 90 to 760 mm, and the length of one chute is usually 1000 mm.

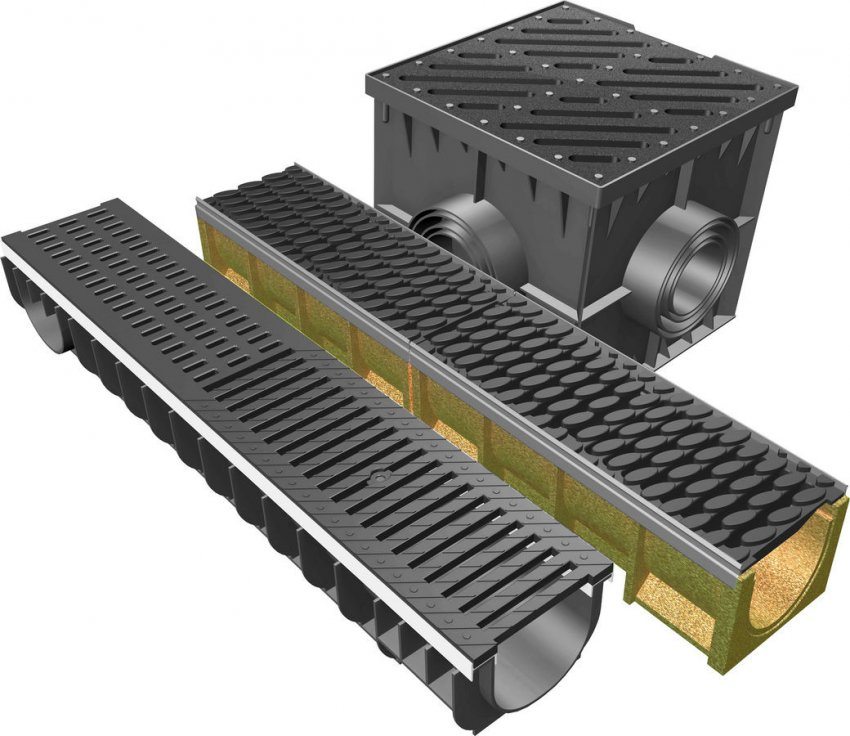

Plastic drainage trays with plastic grid

The use of plastic trays for storm sewers is often found in private construction, as well as in the arrangement of park and garden areas, footpaths and other areas that are not subject to heavy loads. This type is made from extruded polyethylene or propylene and has the following advantages:

- small weight of individual elements in comparison with concrete or polymer concrete drainage trays;

- simplicity and ease of transportation;

- the ability to easily carry out the installation of plastic drainage trays on your own without using specialized construction equipment;

- resistance to moisture, as well as to temperature changes;

- long service life.

In order to increase the strength and wear resistance of plastic structures, they are supplied with special shaped ribs. Products may vary in color and shape. The grille that comes with the plastic drainage tray is usually made of the same polymer or lightweight steel. The second option is stronger and more reliable.

Before you buy a plastic drainage tray with a grate and start installing a storm sewer based on it, you should consider one point.Due to the smooth surface of the material, plastic products have a higher permeability than other materials. This means that a water drainage system based on them can be made with a lower slope than from concrete or composite trays.

The sizes of plastic drainage trays can be different. The hydraulic section is usually 70 to 300 mm, the standard length of one segment is 1000 mm. The weight can be from 1.5 to 20 kg, the maximum parameter is calculated complete with a metal grill.

Composite drainage trays

Composite gutters for storm sewers are manufactured in two versions:

- Polymer concrete - consist of a mixture of plastic and concrete.

- Polymer sand - a mixture of concrete, plastic and sand with the addition of special additives.

According to their performance characteristics, composite trays are located approximately in the middle between concrete and plastic ones. They boast a lighter weight than reinforced concrete storm drains, but are not as light as plastic gutters. They are also characterized by increased strength and wear resistance, but they are not able to withstand such heavy loads as concrete ones. Like plastic products, they have a smooth surface, which improves the system's patency.

In this case, to protect the system from debris, various options for grids for drainage trays are used: cast iron or plastic.

When installing drainage trays made of composite materials, the same special grooves are used as when installing concrete gutters, so additional processing of joints is not needed. The average price of a polymer-sand drainage tray is 430 rubles, a polymer-concrete one - 970 rubles. (in both cases for a one-meter piece without a lattice).

The hydraulic section of polymer concrete gutters is from 100 to 200 mm, from polymer sand - 70-150 mm. The length of one tray, as in other cases, is standardized and amounts to 1000 mm.

Metal gutters for storm sewers

Metal storm drains are far from the most popular option, and there are a number of reasons for this. Metal is more susceptible to corrosion than other materials from regular contact with water. In order for such a product to last as long as possible, the metal layer must be thick enough, which directly affects the weight of the structure. Usually, cast iron is used as the material for making metal gutters, which is very heavy. Accordingly, the installation of a system of metal gutters becomes impossible without the use of specialized equipment.

The price of metal storm drains is also noticeably higher than concrete and even plastic ones. Therefore, they use this option only when it is really necessary.

Useful advice! A good compromise in this case is the use of steel grid gutters. The price of a concrete drainage channel with a cast-iron grate is lower than that of an all-metal product, and a metal grate is characterized by an attractive appearance and a long service life.

Drainage trays with gratings: the price of concrete and plastic models

The unit price is largely dependent on the material from which the gutter is made. So, the prices of concrete trays for storm sewers vary from 1,300 to 2,500 rubles per unit and above. The price of a plastic tray for a storm sewer starts from 500, and a reinforced concrete one - from 1800 rubles.

For example, the Gidrolica drainage tray costs from 530 rubles apiece.It should also be borne in mind that the cost of a product unit largely depends on the components that come with the gutter and its dimensions. For example, the cost of a concrete drainage channel with a grid will be higher than without it.

Related article:

Concrete and plastic drainage well for storm sewers. Types and features of storm sewer structures. Arrangement rules and a detailed description of this process. Types of wells for a private house.

Stormwater drainage trays: selection criteria

On the modern construction market, there are a large number of varieties of gutters for installing a water drainage system from the territory.

When buying, you need to pay attention not only to the size of the drainage trays, but also to the following characteristics:

- The material of manufacture is one of the most important parameters, on which not only the price directly depends, but also the ease of transportation and installation, as well as the speed of arranging the system, which is sometimes very important.

- The presence of a factory slope for water drainage - the device of a drainage tray with a slope will serve well where it is necessary to ensure water drainage on a flat area, as well as where it is not possible to create a slope artificially.

- The quality of the grooves for connecting the gutters to each other - the tightness of the entire system depends on this parameter, if the trays are loosely connected to each other, then part of the water will go into the ground. By the way, when installing plastic drainage trays, it is possible to use a special latch, which serves to increase the reliability of connecting the gutters to each other.

In addition, it is worth paying attention to the main decorative element of the system - the grill. It should not only look attractive, but also effectively perform its main function, that is, protect the system from getting debris into it. For this, the lattice must have a fine-mesh structure.

When choosing a grate for drainage trays, it is necessary to focus on the class of permissible load that they withstand

Installation of concrete, metal or plastic drainage trays with a grid: the cost of work

The cost of installing a storm sewer system depends on the depth to which the gutters are dug. The cheapest (from about 1,800 rubles) will cost the installation of a shallow water drainage system, that is, to a depth of 1 m.Installation deeper than 1.5 m will cost more - 3,900 rubles and more.

Regardless of what material the gutters are made of, they are installed according to the following scheme:

- the type and size of trays is selected, their number and degree of physical activity for the entire system are calculated. Depending on the last parameter, the material from which the gutters are made is selected;

- the depth to which the trays will be buried is determined. You can entrust this business to specialists or you can carry out the necessary calculations yourself. Please note that when calculating the depth of the trench, you need to take into account an additional 10 cm for the concrete or gravel bed. It is also necessary to provide for a slope along which water will be discharged into drains;

- a trench or several trenches are dug with a width of 50 cm and a length according to the number of gutters;

- concrete or cement is poured to the bottom of the trench. To increase the strength of the base, it is recommended to strengthen it with a metal mesh;

- After the pillow has hardened, you need to install rain trays. When installing drainage gutters (concrete or other material), it is recommended to pull a thread into the trench to align the gutters along it. Installed trays are fixed with concrete;

- to protect the linear system from clogging, special grids are mounted on top of the gutters.The price of drainage trays with grids in the kit is slightly higher than without them, however, in this case, you can be sure of a reliable connection of these elements to each other. One of the most optimal sets for the price - a steel grate with a plastic drainage tray;

- if you want to filter water not only from large debris, but also from small particles, you can install special sand traps in the gutters, which will retain sand and other small debris. At the locations of such filters, it is necessary to provide for the presence of special hatches and wells so that they can be cleaned without problems.

Note! If you decide to buy plastic drainage trays, remember that fixing them with concrete is a must. In addition, a special mesh should be laid on the sides of the gutters to reduce the soil pressure on the walls.

Care of storm sewers from trays

In order for the water drainage system to function as efficiently as possible, it must be monitored and cleaned regularly. If you buy concrete drainage trays (or another option) and install an open-type system from them, then to remove the blockage in it, it will be enough just to remove the grate and remove the debris with a shovel or scoop.

If the underground part of the sewer is clogged, then it will be a little more difficult to remove the clog. It is necessary to remove and clean the filters installed to catch small debris. If this measure does not help, it is worth using a special plumbing cable. Sometimes it is enough just to punch a hole in the resulting plug, and the water itself will wash away the barrier.

In particularly difficult cases, hydrodynamic cleaning is used for closed-type systems. It consists in the fact that water is supplied to the system under very high pressure. This type of cleaning requires special equipment, but its use has several advantages. Firstly, water under high pressure removes all blockages in the sewer, and secondly, it cleans the walls of the system, which reduces the risk of blockages in the future.

DIY trays for storm sewers

Despite the relatively low price of plastic drainage trays, there is an option for arranging the system even cheaper - making gutters with your own hands. This will make it possible not only to save money, but also to get a product with parameters that exactly match the needs of your site.

Making a drainage tray with your own hands begins with the production of a mold. For this, boards or laminated plywood with a thickness of 10-15 mm are usually used. A U-shape is made of these materials, the elements of which, for greater strength, can be fastened together using metal corners. If you use boards for formwork, then their thickness should not exceed 25 mm, and the surface should be free of knots. It is best to connect them together with wood screws; they hold the boards well under the action of concrete.

After the main part of the mold for making the gutter is ready, the molding part is made. A regular plastic water pipe cut in half works best for this. The main thing is that its surface is as smooth as possible, since it is along the semicircular part of the gutter that water will flow. A concrete mixture is poured into the finished form.

It is recommended to use the following materials to form strong concrete:

- filtered sand without impurities;

- crushed stone of medium or fine fraction;

- Portland cement M400, which is characterized by a high level of frost resistance and strength (if desired, you can use other types of cement);

- reinforcement with a diameter of 6 mm.

In order for the concrete drainage trays, the installation of which you will carry out in the storm sewer system, are as strong as possible, the ratio of cement, sand and gravel should be 1: 2: 4 or 1: 3: 5. In the second case, the amount of the resulting concrete will be greater, but its strength will be slightly lower.

When calculating the final size of a reinforced concrete drainage channel, it is necessary to take into account the installation of reinforcement. These can be individual rods or a mesh. The latter can be assembled with your own hands, placing the reinforcement rods at a distance of 5-10 cm from each other and connecting them using electric welding or wire. After that, the resulting concrete mixture is poured into the mold, into which the cut plastic pipe is immediately pressed. It is possible to disassemble the mold and remove the pipe one day after pouring the mixture.

Useful advice! A construction vibrator can be used to compact the concrete and remove air bubbles and excess water from it. If you do not have such a tool at your disposal, then you can compact the concrete using a piece of reinforcement.

The concrete cure time is 28 days. After that, each tray must be carefully inspected for defects, pits and cracks. In their absence, you can proceed with the installation of the storm sewer system.

Of the advantages of self-production, it is possible to note not only the exact size of concrete drainage trays you need, the price will also be much lower than when buying a finished product. However, if you decide to buy plastic drainage trays for storm sewers, this will definitely save your time. So the decision on whether to buy or make your own gutters depends only on your personal preferences.