An inevitable companion of the garden area is plant debris in the form of grass and branches. It is impractical to throw away or burn such waste, because it is possible to obtain natural fertilizer from it. It is enough to grind it to the state of chips. A garden shredder can handle this task with ease. However, if there is no financial opportunity to purchase it, then you can make a garden shredder with your own hands. How to do this - this article will tell you in detail.

Content

- 1 DIY garden shredder: basic structural elements

- 2 Stages of creating a garden shredder of branches with your own hands

- 3 Creating a shredder with a stacked saw blade package

- 4 Creating a blade disc shredder

- 5 Assembly Instructions for Double Roll Shredder

- 6 How to make a chopper from scrap materials

- 7 Subtleties when choosing a motor for a shredder

- 8 The main advantages of homemade garden shredders

DIY garden shredder: basic structural elements

Garden shredder, he is a shredder or chipper, greatly facilitates the process of caring for a summer cottage. With its help, you can easily clear the area from branches and grass. Recycled raw materials can be stored in compost pit to obtain natural fertilizer. It is advisable to use the resulting small wood as firewood for heating the house. Shredded chips from fruit trees are ideal for smoking meat.

Design garden shredder simple enough. It consists of the following main parts:

- bunker;

- drive;

- grinding mechanism;

- metal frame with protective cover.

Some models can be equipped with additional elements:

- bunker for shredded organic waste;

- pusher;

- a sieve for regulating the fraction of chips.

The principle of operation of any grinder is the same as that of a meat grinder and is as follows. When the shredder is turned on, the engine starts, which drives the working shaft equipped with the cutting mechanism. At this time, garden debris falls into the receiving funnel and, using a cutting device, is crushed to a state of fine chips.

Useful advice! When carrying out work related to the processing of garden waste, you should use personal protective equipment - glasses, gloves, etc.

Chopping mechanism

Before you start creating a homemade shredder, you need to clearly define the type of waste that it will recycle.This directly depends on its design features and performance. Garden shredders are classified according to three main parameters: the type and power of the engine and the type of shredder.

The following chopping options are available:

- milling, for processing hardwood;

- knife universal;

- roller, for grinding thin branches of trees and shrubs;

- with rotating turbines for shredding thick branches;

- hammer, for the disposal of thin branches;

- line-based trimmer for soft debris.

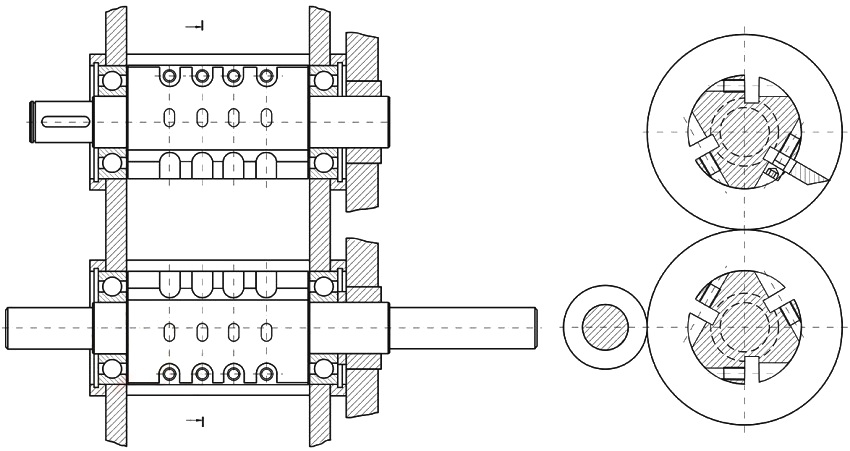

When self-assembling the shredder, preference is given to a knife system or a type-setting of circular saws. You can make a two-roll design, in which two or three knives are installed on a massive disc and rotate towards each other.

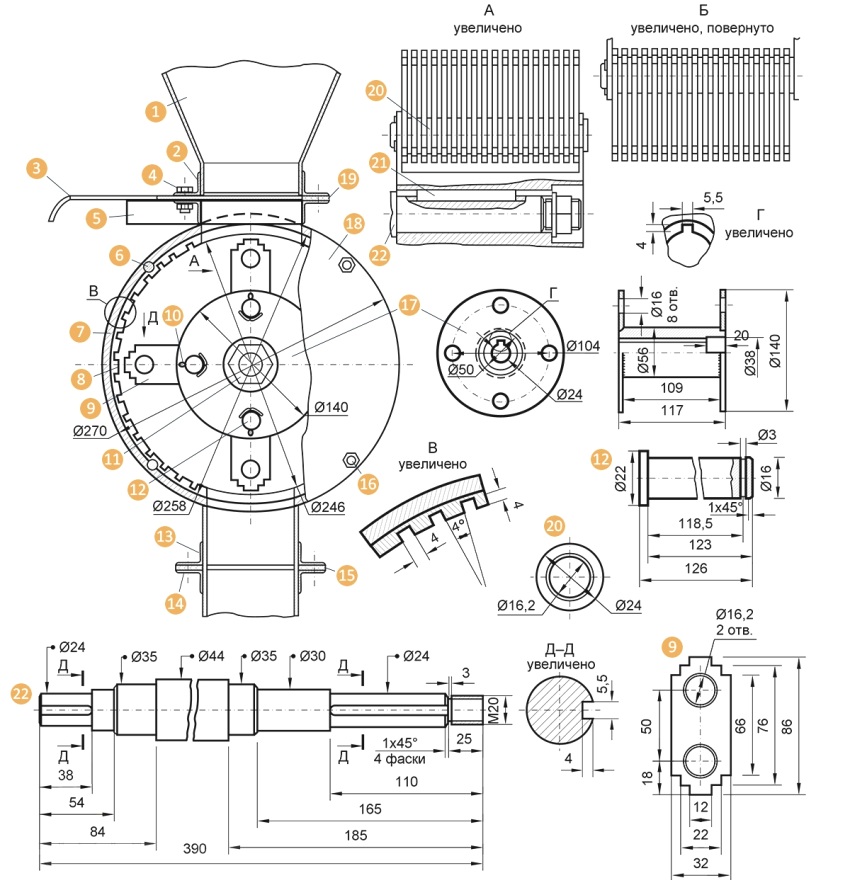

Various types of grinding mechanism: 1 - hammer, 2 - milling, 3 - knife milling and turbine, 4 - knife disc

Engine type and power

The shredder can be equipped with an electric or gasoline engine. Each of them has important advantages and some disadvantages. The gasoline-powered garden chopper is more mobile. Its operation is independent of the power supply. It is capable of processing thicker, larger branches. However, such chippers are more bulky and heavy. In addition, they emit harmful substances into the atmosphere in the course of their activities.

Shredders with an electric motor are lighter and more convenient to use. However, they are inferior in terms of power and depend on the energy resource.

The ability to recycle a certain type of garden waste depends on the engine power. For small volumes of waste, where the diameter of the branches does not exceed 20 mm, a 1.5 kW motor is sufficient. If it is necessary to grind branches with a thickness of 20-40 mm, then it is advisable to use an engine with a power of at least 3.5-4 kW. Shredders equipped with a 6 kW motor will be able to cope with large wood 100-150 mm in diameter.

Another design feature of shredders is the drive type. This function can be performed by a chain, belt or the motor shaft itself, on which the knife mechanism is fixed.

Stages of creating a garden shredder of branches with your own hands

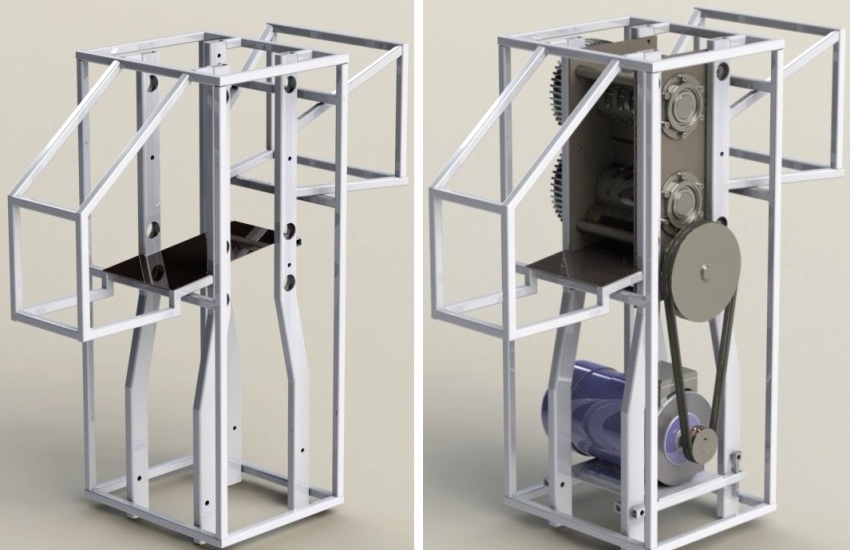

Making a shredder with your own hands is a very laborious process that requires technical knowledge and a high level of practical skills from the master. The whole work consists of two stages. The first, preparatory, is to create a drawing of a garden shredder with your own hands and purchase the necessary materials. The second stage is the assembly of the shredder itself.

Create a shredder drawing

The drawing can be done by hand or use a special design program on a computer. The main structure of the shredder consists of a hopper, a frame, a motor, a shaft with a knife mechanism and a protective cover.

Do-it-yourself examples of drawings of branch shredders clearly show that various crushing mechanisms can be used for the cutting system.

In the case of using a set of circular saws, the drawing of the grinder will be quite simple. A shaft with fixed circular saws in the amount of 15-30 pieces is installed on a metal frame, which is driven by a motor using a belt drive. To do this, pulleys are located at the ends of the shaft and the motor. As the do-it-yourself shredder drawings show, branches for heating a house are shredded precisely thanks to such a cutting system.

Useful advice! For more efficient operation of the shredder, thin plastic or metal spacers should be installed between the circular saws.

To create a shredder with a knife disc shredding system, the drawing indicates the diameter of the cutting disc, the number of knives and their location.The disc itself can be placed vertically or at some angle. The number of knives affects the degree of chopping. They can be from 1 to 3 pieces.

There is an option to create a chipper with two shafts. You can get acquainted with such a grinding system in the video. Do-it-yourself drawings of a branch chopper with a two-roll cutting system are distinguished by the presence of two shafts with knives at once, which are located between the metal plates. Each shaft is equipped with 3-4 knives. The knives themselves are fixed with bolts and offset to the side relative to the center of the shaft.

Four bearings are fixed in the holes of the metal plates, which are responsible for the free rotation of the shafts. And two gears, driven by a motor, ensure their synchronous rotation. The torque from the engine to the drive is transmitted by a chain or belt drive. The distance between the shafts is selected based on the width of the knives and the thickness of the branches.

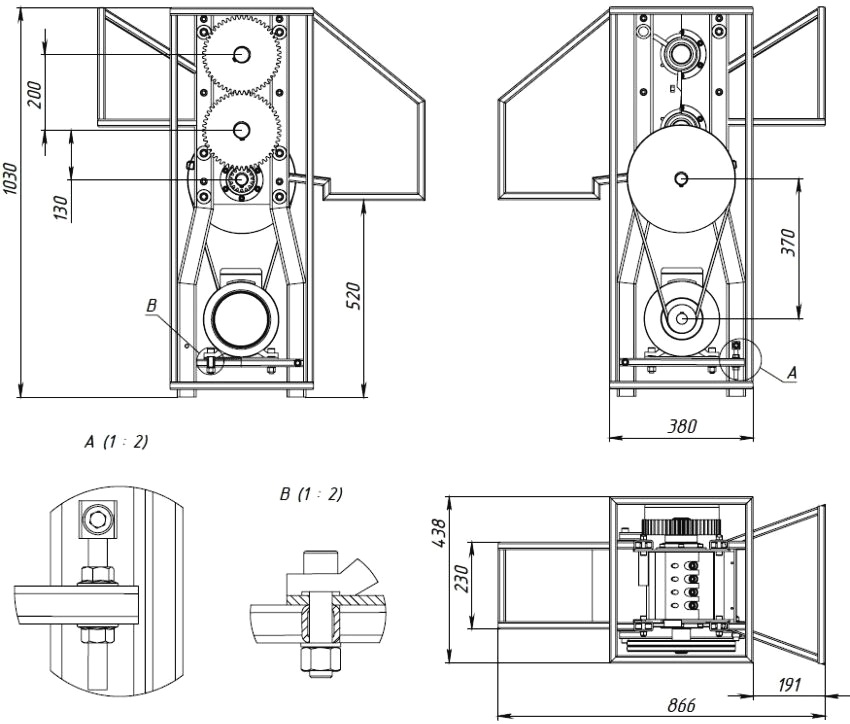

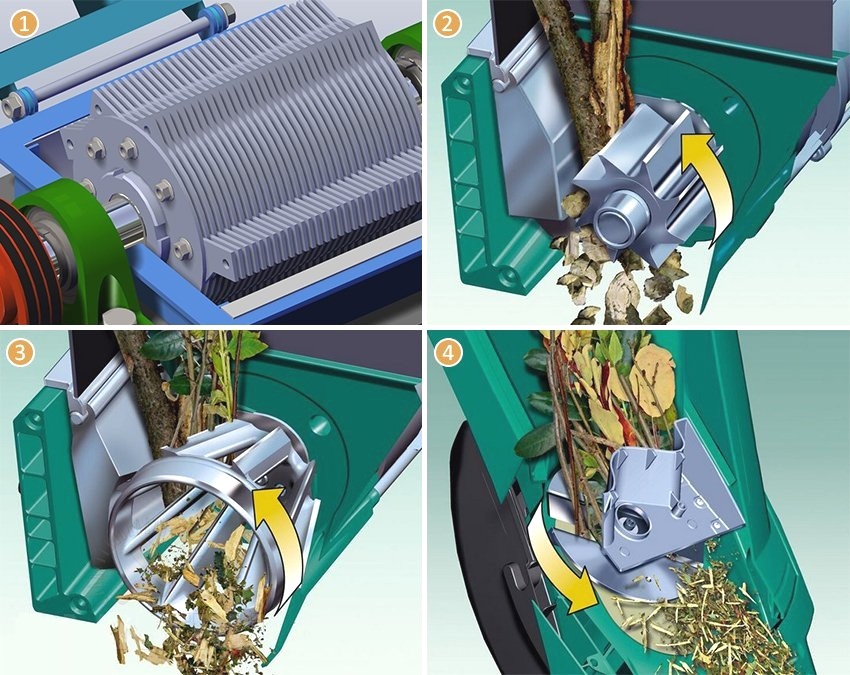

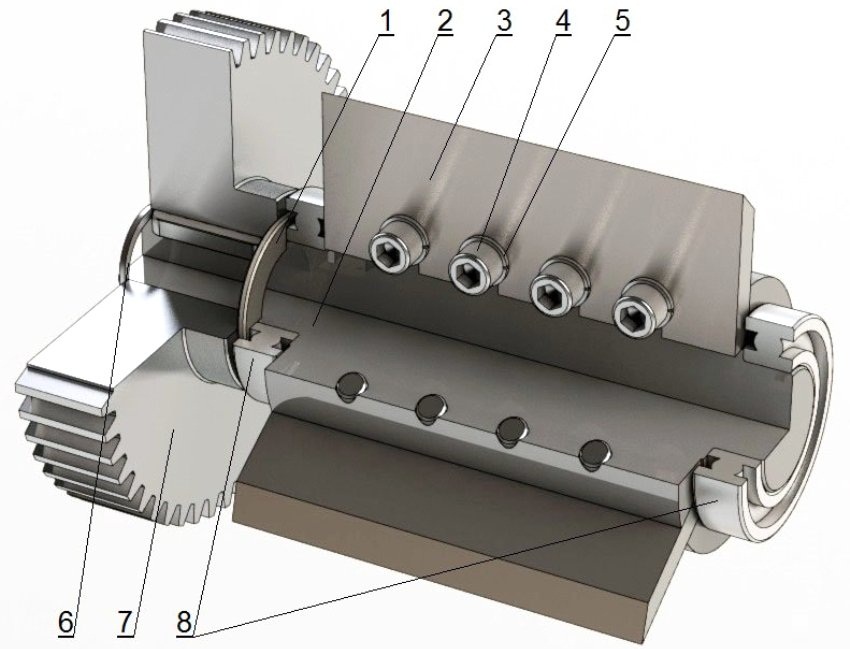

Shredder device: 1 - frame sheathing, 2 - frame, 3 - gearbox housing, 4 - working shaft, 5 - drive shaft, 6 - V-belt, 7 - electric motor, 8 - turntable

Useful advice! Chopping small branches and grass requires high-speed motors. And for chopping up larger branches, strength is important. Here it is necessary to reduce the number of revolutions for powerful engines.

Materials required for making a shredder

To make a garden chipper, where a set of circular saws acts as a chopping system, you need to purchase the following components:

- circular saws in the amount of 15-20 pcs. diameter 18 cm;

- engine;

- 2 pulleys;

- 2 bearings with fasteners;

- metal washers in the amount of 17-22 pieces up to 5 mm thick for separating circular saws;

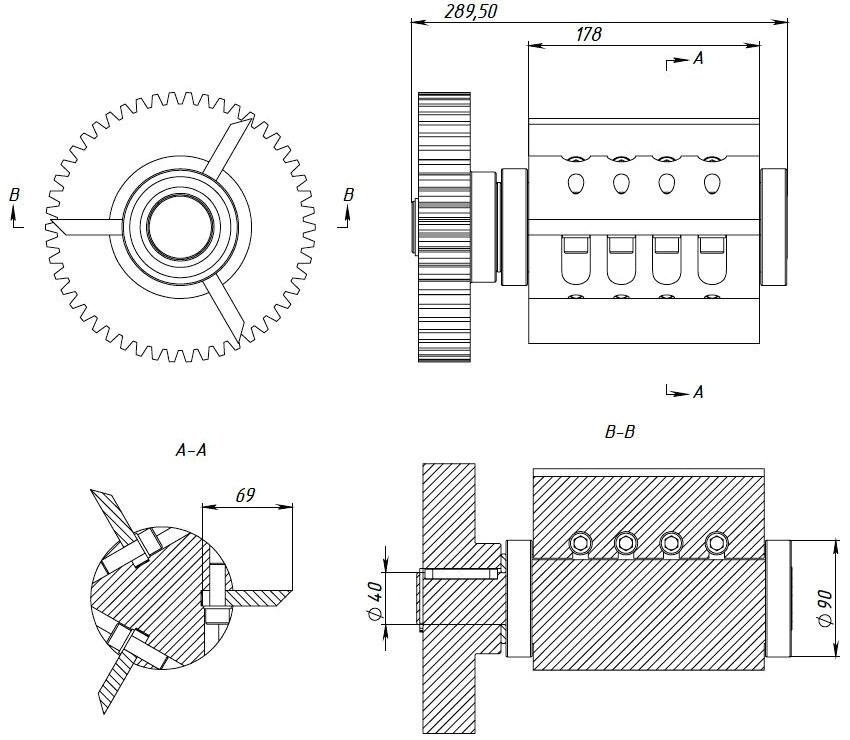

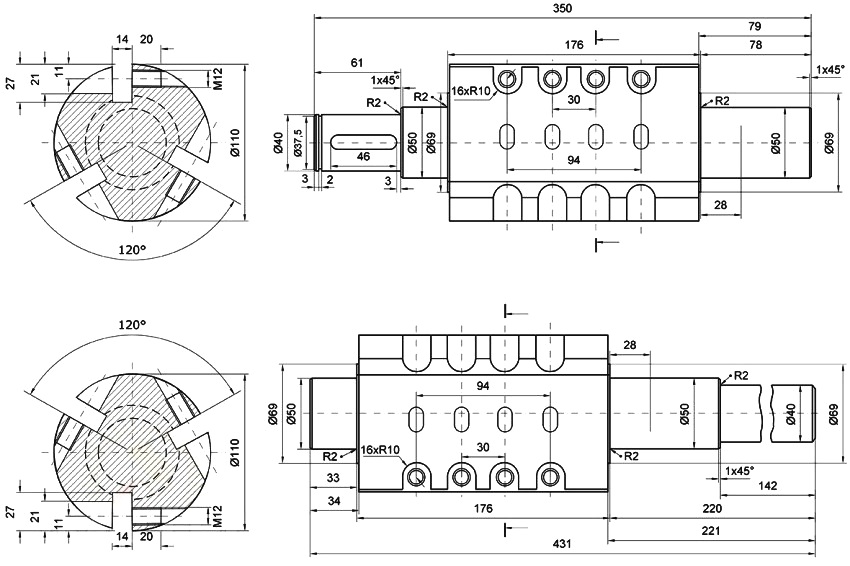

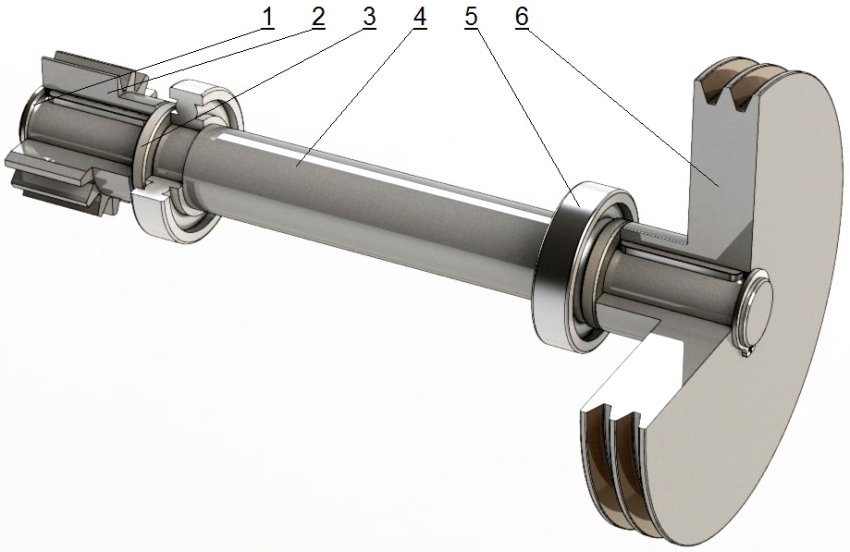

Working (driven) shaft device: 1 - bushing, 2 - shaft, 3 - cutting element, 4 - screw M12 x 35 mm with an internal hexagon, 5 - spring washer A12, 6 - circlip 40 x 2.5 mm, 7 - gear MSGA4-50, 8 - bearing No. 6210

- profile pipes for creating a frame;

- metal sheet with a thickness of about 2 mm for the hopper and casing.

For a shredder with a knife disc you will need:

- engine;

- sheet metal 2 mm thick;

- sheet of metal and knives for the disc.

To create a dual shaft shredder, you need to purchase the following materials:

- gasoline or electric engine;

- two metal plates 10 mm thick:

- a pair of gears to ensure synchronous movement of the shafts;

- a gear or pulley for transmitting torque from the engine to the shafts;

- a pulley for the motor shaft;

Drive shaft device: 1 - retaining ring 30 x 2 mm, 2 - gear MSGВ4-15, 3 - bushing, 4 - shaft, 5 - bearing No. 6207, 6 - driven pulley

- 5 bearings with mountings;

- chopping knives;

- profile pipes to create a frame;

- sheet metal with a thickness of at least 2 mm to create a receiving hopper and a protective cover.

Related article:

Electric garden shredder of branches and grass: an overview of popular models

The choice of a device for technical indicators. How to make a shredder from scrap materials yourself.

As can be seen from the list presented, the design of a disc grinder is the simplest and most affordable. However, this shredder can shred branches up to 20 mm in diameter. But the chipper with two shafts can easily cope with large wood with a diameter of up to 80 mm.

Shredder assembly

Having all the necessary elements, you can safely start creating a design of a garden branch shredder with your own hands based on the completed drawing. The assembly of a garden shredder, regardless of the type of mechanism design, consists of several successive stages:

- Frame installation.

- Bunker creation.

- Assembling the chopping mechanism.

- Installing the engine and chopping device on the frame.

Creating a shredder with a stacked saw blade package

The shredding mechanism of such shredders consists of circular saws, which, alternately with spacer washers, are mounted on the shaft.Each disc has a variety of teeth that can handle even hard wood. Therefore, it will process soft grass, tops and leaves in a matter of minutes. When the saw teeth are dull, they can be easily replaced with new ones.

The shredder shaft can be turned on a lathe or used ready-made from the gearbox of an old car. The distance between adjacent saws should be about 10 mm. A smaller gap will reduce the work area of the shredder. Making a larger gap will tend to cause small branches to get stuck.

Useful advice! The saw teeth should not be located on the same line, fixing them on the shaft. Better to set them randomly. This reduces the load on the shredder shaft and motor.

It is better to use an electric motor, which is practically silent during operation and does not emit harmful substances into the atmosphere. For crushing coarse material, you can use walk-behind tractorwhich has a lot of power. The motor should be placed on a movable support so that the tension of the drive can be adjusted.

The frame for the shredder can be welded using channels, angles or profiled metal pipes. A persistent metal profile bar can be welded to the base of the structure, which will become a support for stems and branches during crushing. When creating pedestals for bearings, it is important not to skew. The axes of the motor and shaft must be in parallel planes.

The design of the bunker deserves special attention. It can be made from sheet metal. The container should be strong enough to withstand the impact of flying chips from branches. With the help of a movable base plate in the body of the hopper, it is possible to adjust the size of the chips. So, smaller fragments are suitable for fertilization, and larger chips are suitable for kindling.

The size of the receiving socket should be larger than the length of the arms to protect them from damage. This also contributes to the ability to guide branches into the shredder at a comfortable angle.

Such a do-it-yourself garden shredder of branches and grass is able to cope with both soft waste and hard thick wood. However, its main problem is the clogging of the space between the saws, which needs regular cleaning.

Creating a blade disc shredder

You can create such a grass chopper with your own hands from scrap materials. Since it is designed for crushing soft debris, its design will be very simple, but it will not have a high strength index. You can weld a sheet metal hopper, or you can use a regular metal bucket. A case from an old fan will also work.

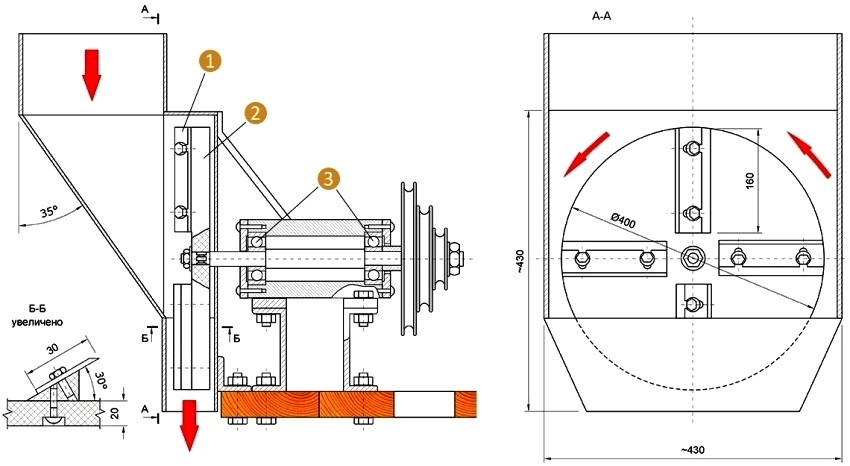

Drawing of assembly of a shredder with a knife disc: 1 - knives 4 pcs, 2 - disc cutter, 3 - bearings No. 307

To create a cutting system on a metal disc, knives are inserted into special slots, which can be pre-made from a leaf spring from a car. The disc is mounted on the shaft. Next is the receiving box. For such a shredder, a low-power 1 kW motor is suitable. All the details of creating a do-it-yourself garden electric grass grinder can be viewed in the videos offered on the Internet.

Assembly Instructions for Double Roll Shredder

Work begins with the creation of the frame. To do this, using an angle grinder from a profile pipe, two workpieces with a length of 80 cm and four parts with a length of 40 cm are cut. Next, short sections are welded between two long workpieces at right angles. The two internal parts must be spaced apart from each other so that the chopper drum is securely installed.

Useful advice! For the device to be mobile, the structure must have wheels for movement. To do this, two racks are welded to the frame, on which an axle with wheels is attached.

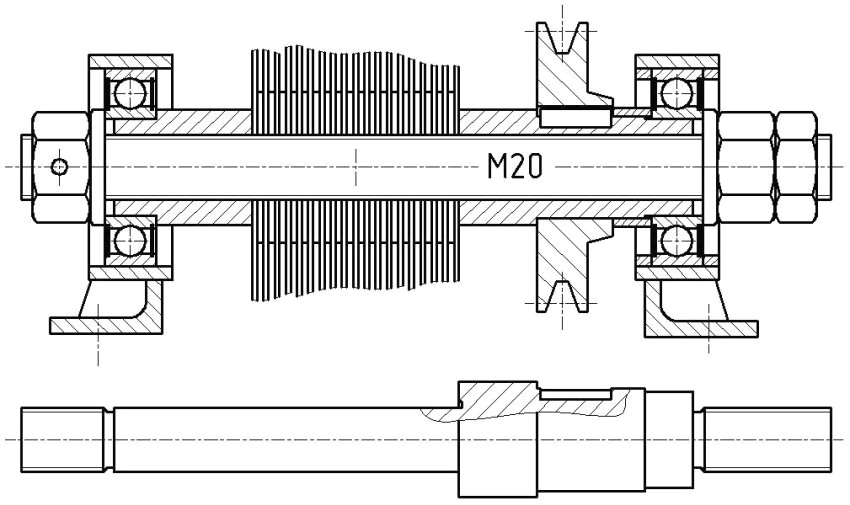

The next step is to create the shafts for the chopping drum. If you plan to install four knives on one shaft, then we use a square metal blank. We make both ends of it round so that they can enter the bearings. For three knives, you need a round blank in which the central part is sharpened. Three flat cuts are made in it for the subsequent installation of the knives.

To create knives, you can take a small piece of a KamAZ leaf spring. Bolt holes are made in the knives. Then you should run sharpening knives on a grinding machine, where the angle of the cutting edge is selected with a value of 35-45 degrees. Further, the sharpened knives are applied to the shaft and the places of their attachment are marked, in which holes are created, and a thread is cut.

Next, we proceed to create a grinding mechanism. Round holes are made in two metal walls using a welding machine for installing bearings. Using special pads and bolts, we install the bearings inside the metal walls. We insert shafts into the bearings, securely fixing them. They should be located at a sufficient distance to exclude the possibility of their contact. Next, the walls of the drum are connected using metal threaded studs and nuts.

Now let's start creating the receiving hopper. To do this, four parallelepipeds are cut from thin sheet metal. Further, each edge is bent by 4 cm. A short section in one direction, a long one in the opposite direction. We connect all the parts using self-tightening rivets or welding. Holes for fasteners are made on the bent edges at the base of the box.

Now gears are put on the shafts to synchronize the movement, and the whole structure is installed on the frame and secured with bolts. Then the motor is installed, which is connected to the shaft by a belt drive or chain. It is better to take an engine of high power, but with a low speed. At the end, a receiving hopper is installed and fixed. Then a protective cover is put on all rotating parts of the shredder to prevent foreign objects from entering the shredder.

The main advantages of such a unit are high power and technical ability to chop thick branches with a diameter of 20 to 80 mm. This will depend on the number of knives and the number of revolutions. On numerous sites on the Internet, detailed recommendations are presented on how to make a do-it-yourself chopper of branches. Video examples more clearly show the entire assembly and installation process of a homemade device.

How to make a chopper from scrap materials

Many thrifty and thrifty owners are in no hurry to throw away old tools and household appliances. They find new uses for them. It is worth showing a little imagination, turning on logic and ingenuity, and you can create a real assistant in the household from improvised tools and old parts. Consider some simple options for making a homemade twig and grass chopper from simple and affordable materials.

Shredder from grinder and vacuum cleaner

One such homemade design is a do-it-yourself garden chopper made from a grinder, an old vacuum cleaner and lawn mower knives. One well-known inventor Vladimir Belyaev proposed his own chopper of branches with his own hands, the video of the creation of which inspired many to modernize this idea and offer their vision when creating a summer cottage assistant. Next, we will consider one of the interesting and popular options.

To create a simple, but productive design, you will need an old working vacuum cleaner, a 3.2 kW Makita grinder, lawn mower knives, a stable wooden base, a receiving funnel and a metal table with a vertically welded sheet of metal.

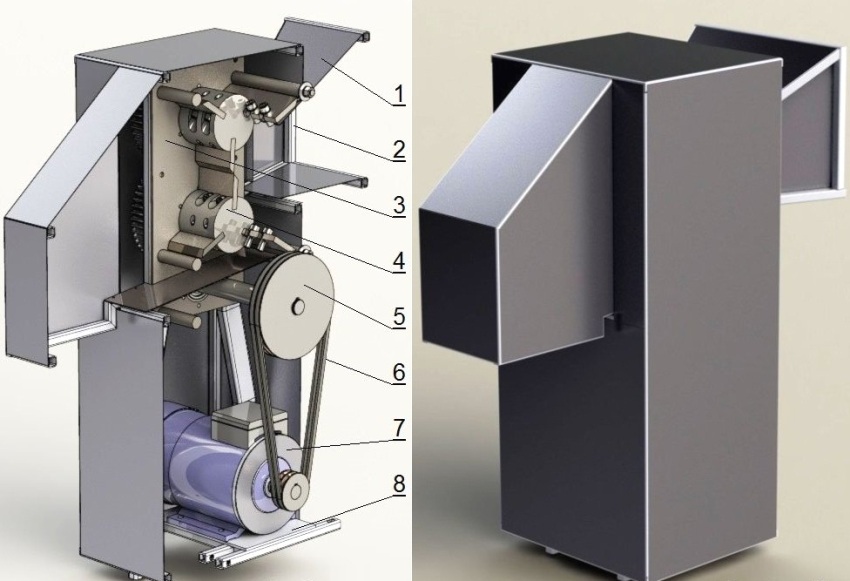

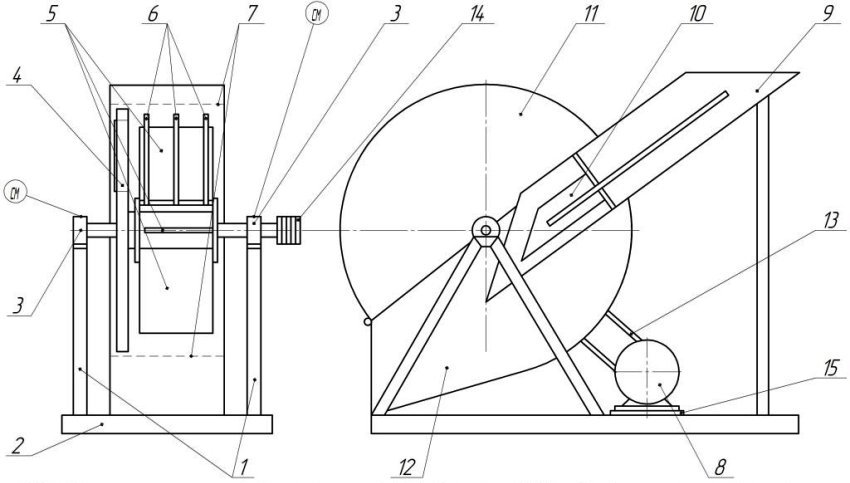

Drawing of a shredder for do-it-yourself manufacturing: 1 - racks, 2 - base, 3 - rolling supports, 4 - disc cutter, 5 - fan blades, 6 - hammer crusher bits, 7 - calibrating mesh, 8 - drive motor, 9 - feed hopper , 10 - prepressor, 11 - hinged shredder casing, 12 - stationary shredder casing, 13 - belt drive, 14 - pulley, 15 - belt tensioning mechanism

The receiving funnel is horizontally mounted on a vertical metal sheet welded to the table. This sheet must be thick to hold the grinder attached with bolts and the knives mounted on it. If the seat of the three-blade lawn mower knives is not compatible with the angle grinder, then you need to sharpen them so that the knives sit securely. To prevent the crushed mass from getting stuck between the knives, a pipe from an old vacuum cleaner is attached to a metal sheet, which supplies air. It is desirable that the grinder and the vacuum cleaner turn on at the same time.

The metal table is located on a wooden stationary base. A protective cover should also be installed to prevent the back movement of the chopped branches.

Such a simple version of a garden shredder with your own hands, the video is a clear confirmation of this, can be easily created at your dacha, without complicated stages of work and the acquisition of additional materials.

Washing machine shredder

A garden shredder can be crafted from an old washing machine. To do this, you will need a body and an engine from technology, an old saw, a bucket and other parts, and tools for fastening the structure.

A side hole is made in the body of an old washing machine for the outlet of recycled materials. Knives are attached to the bottom of the container using a special sleeve, which can be made from pieces of an old saw. An existing one built into an old washing machine is used as a motor. The receiving container for shredded waste is installed near the side opening.

Drill Shredder

Another elementary invention is a homemade shredder using an electric drill. The principle of operation of this mechanism resembles a vegetable cutter.

Drawing of a hammer shredder: 1 - loading hopper (metal 1 mm), 2 - edging of the neck of the loading hopper (corner 25x25 mm), 3 - damper / latch (metal 1 mm), 4 - M6 bolts for screed (8 pcs), 5 - framing of the loading hole in the housing (equal angle corner 25 mm), 6 - M8 studs (8 pcs), 7 - outer drum of the housing (pipe 270x6 mm), 8 - stator with grooves (pipe 258x6 mm), 9 - hammers (metal 3 mm hardened to HRC 45-47 hardness, 72 pcs), 10 - bolt with a diameter of 3 mm (4 pcs), 11 - M20 nut with a spring washer, 12 - hammer axis (circle with a diameter of 22 mm, 4 pcs), 13 and 14 - piping strapping (equal angle corner 25 mm), 15 and 19 - rubber gaskets 3 mm thick, 16 - M8 nuts for flange fastening (8 pcs), 17 - hammer rotor, 18 - flange (5 mm metal, 2 pcs), 20 - distance washers (metal 3 mm, hardened to HRC 45–47, 70 pcs.), 21 - retainer, 22 - drive shaft

To create a structure, you need to take an old stool. Drill a 12 mm hole in it. A housing with a bearing is attached to the back of the stool. A bucket with a hole of the same diameter is installed on the stool and fixed with self-tapping screws. A bearing is inserted into the hole, onto which a shaft is installed with high-speed steel knives fixed to it. A two-mode drill is connected to the end of the shaft from the bottom of the stool through a keyless chuck.

Soft raw materials are thrown into the bucket and an electric drill is started. After thorough grinding to the desired state, the mulch is removed. This design is designed for a small amount of recyclable waste.

The process of making and sharpening a knife deserves special attention. Sharpen on one side. The sharpened plane is at the bottom.For chopping freshly cut grass, the diamond-shaped blade is ideal, in which you can round the blades. This will allow the grass to slide freely over the cutting edge of the chopping knife without getting wrapped around it.

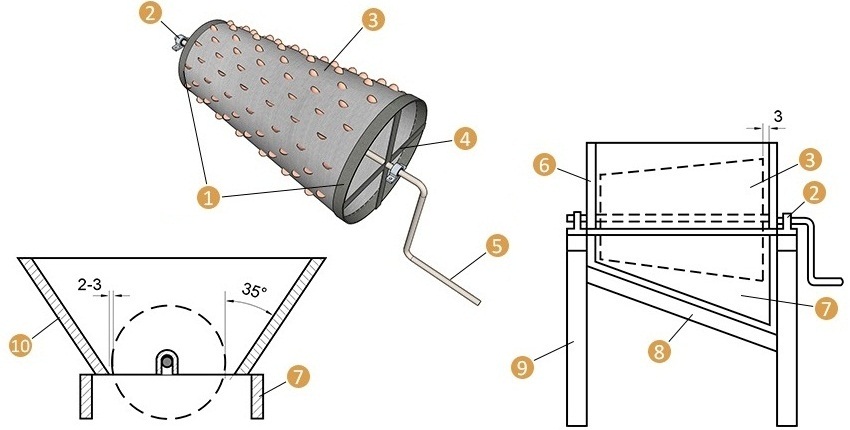

Drawing of a hand grinder, for which you can use a drive from an electric drill: 1 - shell, 2 - bearing, 3 - drum, 4 - cross, 5 - handle for rotation, 6 - end wall of the body, 7 - shield, 8 - chute board, 9 - stand, 10 - side wall of the case

From the proposed options, we can conclude that you can create a garden shredder with your own hands from any available material. It is enough to have an electric motor adapted for a 220V network, any round container of sufficient size, a steel sheet, a hacksaw for wood or a saw from an old lawn mower to create a cutting mechanism.

Subtleties when choosing a motor for a shredder

A certain engine power ensures the required performance of the shredder. When choosing an engine, you should be guided by some important rules:

- For small branches, choose an engine with a power of at least 2 kW. The higher the power rating, the greater the productivity and technical capability of the shredder.

- For crushing soft waste in the form of grass and leaves, a 1.5 kW engine will suffice.

- Gasoline engine power must not be less than 6 HP.

- Do not use too powerful motors over 3.5 kW. They consume a lot of electricity, but this does not achieve the maximum performance of the unit.

- The speed of the engine does not have a big influence on the performance of the chopper. Here, the frequency of rotation of the knives is important, which is ensured by the V-belt transmission.

- For reliable chopping of branches, the speed of the knife shaft should be no more than 1500 rpm. This is due to the correct selection of the diameters of the driving and driven pulleys.

Useful advice! It is better to make pulleys for a belt drive for 3-4 strands. This will allow you to change the speed on the shaft by shifting the belt, which is necessary for different operating conditions of the shredder.

The main advantages of homemade garden shredders

A homemade shredder does not require too much respect for itself. It can be used for more than just chopping grass, leaves and branches. It will perfectly recycle any household waste. It can be used to grind the fruit of fruit trees for the subsequent preparation of puree, jam or homemade wine.

Homemade shredders will cope with branches up to 100 mm in diameter, while factory units simply will not let such large plants pass. Also, there is no need to monitor the moisture content of raw materials for processing. And for factory shredders, such negligence is unacceptable. Since in most models the engine is located at the bottom of the structure, the possibility of moisture getting on it must be excluded, which will inevitably lead to damage.

An important argument in favor of a homemade device is the cost of the entire structure, which will be much lower than the price of the finished shredder. This also applies to replacing a failed part that is not costly.

In addition, the homemade garden chipper is distinguished by the degree of productivity. All garden waste that falls on the shredder is instantly processed into small chips.

As you can see from all of the above, you can create a reliable and faithful assistant for chopping garden debris with your own hands from scrap materials.It is enough to have some skills and abilities of plumbing work, to have in your garage parts of old equipment, the necessary tools and materials. Further, having chosen the most acceptable way for yourself, sketch out a drawing of a branch chopper with your own hands. Videos of various versions of a homemade shredder can be viewed on the Internet. Based on the drawing, prepare all the necessary elements and start assembling the shredder.

If you are not confident in your own abilities, at present you can buy a home-made shredder of branches from the proposed options, which will meet all the requirements and will satisfy your wishes at an affordable cost.