A modern car workshop must be equipped with a special device in the form of a hydraulic press. With the help of such a tool, the dismantling of car parts, the manufacture and adjustment of the shape of auxiliary metal blanks and a number of other technological operations are carried out. How to choose the right manual hydraulic presses, the characteristic features of the device and the areas of its use, you can learn from this article.

Content

- 1 What is a hydraulic press: device description

- 2 Design of a manual hydraulic press

- 3 Operating principle of a hydraulic press

- 4 Characteristic features of the operation of hydraulic presses

- 5 Manual hydraulic presses: equipment classification

- 6 Which hydraulic press to buy: table or floor

- 7 Basic rules for the operation of a hydraulic hand press

- 8 Other field of activity of the presses: hydraulic press for cable lugs

- 9 What can you make a hydraulic press machine

- 10 How to bleed a hydraulic jack: video instruction

What is a hydraulic press: device description

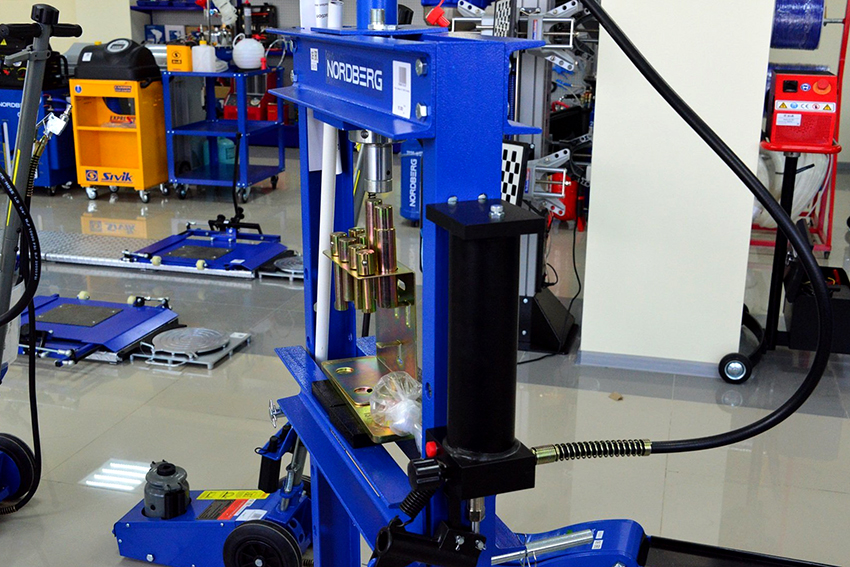

The inventor of the hydraulic press is Joseph Bram, who patented his discovery in 1795. Initially, the device was used to extract vegetable oil, squeeze juice from grapes and bale hay. Today, such a special machine is used to process metal elements and workpieces, with its help, plastic, plywood and rubber are processed.

The device is often used in auto repair shops for bending and compressing materials, pressing and pressing out bearings, when performing overhaul of gearboxes, suspensions, and the power plant of a car. No significant effort is required to use the device.

The press includes a frame with a bed, two hydraulic cylinders with different diameters, a hydraulic pump and a pressure gauge. Both cylinders are interconnected. Each of them contains a special mineral oil. In appearance, the device resembles a jack that works according to the laws of hydraulics.

Important! The frame of the hydraulic press must be made of thick steel, which has a positive effect on the maximum load threshold value.

The control of the force required for processing workpieces is carried out with a pressure gauge. The presence of control and measuring equipment allows you to adjust the load force, which is necessary for a high power tool.

Hydraulic presses are used for pressing and pressing out bearings, repairing auto parts, as well as bending and compressing materials.

The hydraulic press can be manual, pneumohydraulic or electrically driven. The manual device develops a force of up to 20 tons. It is mainly used in small workshops and garages. The pneumohydraulic product includes a hydraulic booster and a pneumatic cylinder. Such a hydraulic press of 40 tons develops an effort. Electric models are used in production. The maximum possible force for such hydraulic presses is 100 tons.

Design of a manual hydraulic press

The hydraulic press for metal consists of the following elements. A container is used to pump the working fluid into the hydraulic cylinder. Safe operation of the device is ensured by the presence of a shut-off valve and a discharge valve. The mechanism is driven by a special lever that supplies fluid to the chamber of the hydraulic cylinder. This is carried out as a result of the movement of the piston, the rod of which creates a force that acts on the actuator of the device.

A distinctive feature of the hand press is the use of a lever mechanism, by means of which the rod can be set in a certain position, depending on the nature of the technological operation. For presses with high productivity, a foot drive is installed.

As a drive, a manual hydraulic pump is used here, which carries out reciprocating movements of the working element of the device. It consists of a body, a handle and a container for liquid. The hydraulic cylinder can be plunger or piston, depending on the used working fluid for the press. If an aqueous emulsion is used, then the first type of device is installed. Viscous mineral oil requires a hydraulic press piston cylinder.

Important! A manual hydraulic press can be used for parts that are located in hard-to-reach areas of structures.

Operating principle of a hydraulic press

Next, let's take a look at how a hydraulic press works. The principle of operation is based on Pascal's law, which determines that pressure can be transferred without change to any point in the liquid. When acting on the piston, force is transmitted through the working fluid of a vessel with a smaller diameter to a cylinder with a large section. This contributes to an increase in the applied force as many times as the area of the piston of the larger vessel exceeds the area of the smaller hydraulic cylinder.

The pressure in cylinders with different sections depends on the surface area of the piston and the applied force. If you apply a little force to the small cylinder, you can get significant resistance from the side of the larger vessel. For best results, the smaller piston must travel a greater distance.

The principle of operation of a hydraulic press can be compared to the principle of operation of a mechanical lever. The force transmitted over his shoulder increases in proportion to the ratio of the lengths of the shoulders (large and small). In hydraulic devices, fluid acts as such a lever. The applied force will be increased in proportion to the areas of the working surfaces of the hydraulic cylinders.

Characteristic features of the operation of hydraulic presses

The hydraulic manual metal press has a number of advantages. With the help of such a device, operations of varying complexity can be performed, performing them quickly and with high accuracy.This is due to the effect of high fluid pressure, which allows precise changes in the shape of the workpieces, recreating complex configurations of products.

The design does not include overload protection devices, which simplifies the operation of the tool and contributes to its low cost. When using the device, it is possible to smoothly adjust the working force and keep the selected parameter for a long time. The pressure value is not influenced by the position of the movable work table. The hydraulic installation allows you to change the parameters of the length and height of the working stroke.

What does the press look like and why is it needed? With the help of a manual device, you can mount and dismantle elements of bearing assemblies, shafts, bushings. The device makes it possible to carry out stamping and calibration of metal parts. A manual hydraulic press is used to adjust and change the configuration of metal products. The device is a versatile tool that can be used not only in auto repair shops, but also in repair shops, home workshops and garages.

The machine can work in various conditions. Unlike a stationary device, which has impressive dimensions, such a tool does not take up much space, which saves space and eliminates the need to build a heavy base.

Independent use is characterized by maximum safety, simplicity and ease of use, which helps to reduce labor costs. The hydraulic press has an affordable cost, which is supported by a long period of operation.

The disadvantages of a hydraulic press include a low speed of the working surface. It is impossible to eliminate such an error. Doing so can cause a water hammer when the work surface contacts the workpiece, resulting in device failure.

Manual hydraulic presses: equipment classification

Hydraulic hand presses can be classified according to a number of parameters. Based on the direction of movement of the working rod, models are distinguished in which this element can move up or down. Most modern devices are equipped with a stem that moves downward.

Depending on the dimensions of the hydraulic press, there is a floor-standing and table-top type of device. Various methods of influencing the mechanism are also applied to such a tool, ensuring the operation of the device. The manual hydraulic press is driven by a manual pump, which in some models can be replaced with an electric hydraulic pump, which increases the productivity of the equipment. The floor-standing instrument has more impressive dimensions and is operated using a foot switch.

Based on the type of construction, the manual hydraulic press machine can be horizontal or vertical. The devices differ in the direction of movement of the pressing plate. It can move horizontally or vertically.

The horizontal hydraulic press brake is used for bending, shearing and straightening metal parts. Vertical hydraulic press is used for pressing and unpressing elements.

Useful advice! The horizontal manual hydraulic press can be used for waste disposal - pressing waste paper, corrugated cardboard containers, textiles, plastic bottles, feathers, fluff and other items.

The expansion of functionality is facilitated by the availability of various stem attachments, which are included in the complete set of modern models of hand presses. The equipment is characterized by a good degree of mobility. Floor and table fixtures are equipped with special wheels that allow you to effortlessly move the tool to the location of the parts for processing.

Which hydraulic press to buy: table or floor

When choosing a floor or table type of device, you should first of all decide what the press is for.

The floor device is impressive in size. The instrument is placed on the floor. It is used for processing dimensional parts. The floor type of hydraulic press is often chosen by large service stations, whose main activity is car repair. Thanks to such a device, the productivity of technological processes is increased. In addition, the presence of a hydraulic press contributes to the expansion of the list of services provided.

Useful advice! For the rapid execution of technological processes that require high power, it is more expedient for a service station to purchase a hydraulic press with an electric drive.

Floor standing hydraulic presses are selected based on the characteristics of the hydraulic cylinder and the design parameters where it is installed. An important factor is the maximum value of the force that the tool can exert on the workpiece being processed. This criterion varies in the range of 5-20 tons. The effective operation of the floor press depends on the distance that the rod travels when acting on the part.

Important! When choosing a hydraulic press, you should study the technical parameters of the tool, which are displayed in the equipment passport.

Special Features of Benchtop Hydraulic Garage Press

The bench press is more stable. It features an extended working table adjustment range. This makes it possible to machine parts of different sizes.

A benchtop hydraulic press is often chosen for a home workshop or garage. The maximum lifting capacity of the device reaches 12 tons. Such a tool is characterized by small dimensions and weight, which makes it easier to operate. It can be installed on a workbench to save valuable floor space.

When choosing a device, one should be guided by the size and weight of the device, the type and characteristics of the working platform, which differs in different designs and dimensions. The structure can be equipped with grooves for mounting additional elements. An important question is how much the press costs. A floor instrument can be purchased for 30 thousand rubles. The price of a table-type hydraulic press is on average 10-20 thousand rubles.

Some models have the ability to move the press along the frame relative to the stem. Damping elements may be included with the tool. They are necessary to compensate for the excess pressure that is applied to the structure.

Related article:

Knife sharpening machines: a convenient way to keep your working tool in order

What tools can be used for. The main types of structures. How to choose the right one. Review of popular models of sharpening devices.

When choosing a hydraulic press of any type, you should also take into account the material of manufacture and the thickness of the base plate of the fixture, where the part is installed during its processing.

Basic rules for the operation of a hydraulic hand press

Having decided why you need a press, you can purchase the model you like.However, for the effective and durable operation of the device, it is necessary to adhere to certain rules for using the device. First of all, attention is paid to the correct installation of the tool. All the necessary information on this matter is described in the accompanying document for the device, which is given by the manufacturer.

Let's consider the basic recommendations that should be followed in order to avoid frequent breakdowns of the press and the need to repair it. Before each use and during operation, it is required to check the level of the working fluid in the cylinders. The filling of the vessel will determine the pressure value that the hydraulic cylinder is able to create. It is necessary to regularly lubricate the rubbing and moving structural elements.

The condition of the O-rings is checked periodically. Over time, these elements lose their elasticity. Before starting work, check the reliability of the fastening of the part to be processed.

Malfunctions may occur during the operation of an industrial press. Information about the possible causes of their occurrence and the rules for elimination is contained in the instructions for the tool.

Other field of activity of the presses: hydraulic press for cable lugs

The hydraulic press is widely used for crimping cable lugs for high voltage lines. With the help of the device, the process of mechanical crimping of the connection is carried out, which after processing will have greater strength, conduct electric current well, not overheat, which reduces the likelihood of damage to contacts and the occurrence of accidents.

The manual hydraulic lug press is designed to work with cables with a cross section of 5-400 mm². When choosing a tool, some parameters of the device should be taken into account. The press must have a pressure limiting valve. Such devices are more reliable because they prevent overpressure.

An important criterion is the type of pressing head, which can be open or closed. The first option provides more convenient and simple operation for any cable length. To work with a closed-type press, you must first open the stopper, remove the matrix, insert the wire and the tip, and close the device. Only after such manipulations is the cable crimped.

When choosing a hydraulic press, it is important to consider the cable cross-section diameter. Depending on this, all tool models can be divided into types. Variety PG-70 is used for wires with a cross section of 4-70 mm². Type PG-120 is designed for cables with a diameter of 10-120 mm², PRG-240 - 16-240 mm². The hydraulic press PGR-300 is capable of working with a cable with a cross section of 16-300 mm². The PG-1000 model is designed for wires with a diameter of 400-1000 mm².

All instrument models can work with copper or aluminum wires. Many modern devices are equipped with a rapid traverse mechanism and rotating heads. Manual hydraulic presses KBT of domestic manufacturers are very popular. This is due to the democratic cost of the instrument and the high quality of its performance.

Important! The kit of the KBT hydraulic press includes eight replaceable dies for crimping.

What can you make a hydraulic press machine

The most popular tool for making a hydraulic press is a jack, which is based on the hydraulic principle. According to the laws of physics, the liquid in it under pressure does not decrease its volume.Therefore, no power loss is observed when exposed to the workpiece. In addition, the jack is characterized by high efficiency, due to which you can count on a significant compression force.

To make a homemade device, you can use the hydraulic press scheme from a jack, which can be found on the Internet. At the first stage, a structure frame is created from a steel profiled pipe, metal corners and a plate. A jack is installed between the thrust plate and the platform, and it is necessary that, when retracted, the rod tip is inside the retainer. The base of the tool is bolted to the movable stop.

For the manufacture of do it yourself hydraulic press use a jack

For crimping metal blanks, the product is placed on a platform, the jack is lifted when the lever is applied. In this case, the pressing process takes place. It is important to know how to lower the hydraulic jack and what needs to be done at the end of the work. For this, the tool is equipped with a by-pass valve. It is a round head with protruding shoulders. It must be loosened, causing the device to lower.

The jack also has a check valve that, when closed, pumps oil into the piston. Normal operation of the device indicates that there is sufficient fluid in the system. If the tool starts to work slowly or comes to a complete stop, it means that it is low in working fluid. You need to know how to fill the hydraulic jack with oil. For this there is a special filler plug on the device body, which must be unscrewed. Next, the tank is filled to the required volume. At the end of the procedure, the jack is pumped.

The manual hydraulic press is a multifunctional equipment that is widely used in auto repair shops. It is an indispensable assistant for your home workshop. When choosing a device, it is important to determine the scope of its use. For domestic purposes, a device designed for a force of up to 20 tons is sufficient, and for a large service station, a hydraulic press of 50 tons is needed. You can save money by making a press from a jack with your own hands.