Tile today is one of the most common finishing materials. For its correct laying, a number of tools are used, one of which is a tile cutter, without which tile laying is simply impossible. This article will discuss the main characteristics that a manual tile cutter has: price, design differences, as well as rules for handling the tool.

Content

Which tile cutter to choose: the main characteristics of the tool

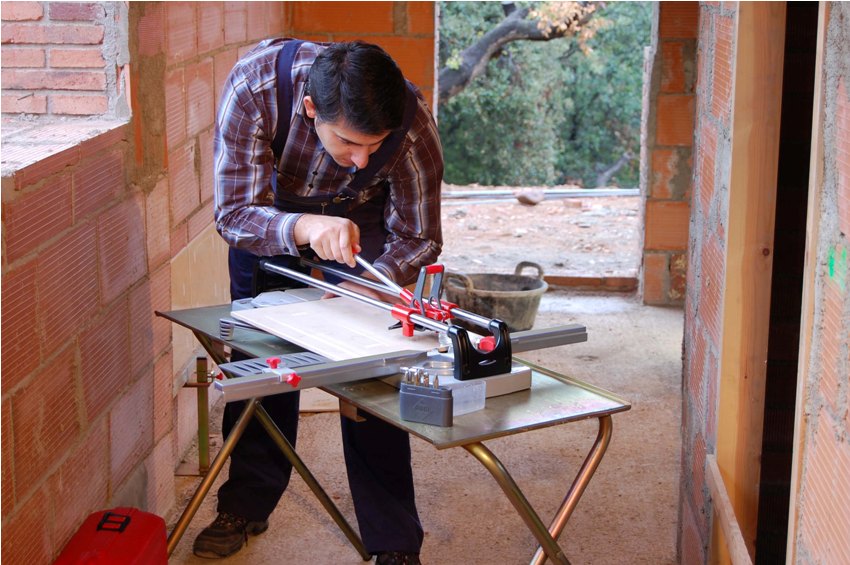

Hand-held tile cutters are used not only for cutting tiles, but also for working with other materials (for example, glass or stone). The choice of this or that type of such a device primarily depends on the purpose.

Functional manual tile cutter as follows: first, the tile is fixed in a rail device, after which a roller, which has a diamond coating, is drawn along a predetermined cutting line. Thus, the tiles are shortened to the required size.

In order to better understand the process of working with this device, it is recommended that you familiarize yourself with the instructions, which describe in detail how to use manual tile cutters. Videos on this topic can also be found on the Internet.

There are many types of handheld cutting devices available today, but they are all used to cut the following materials:

- ceramics;

- a rock;

- porcelain stoneware;

- glass;

- clinker brick.

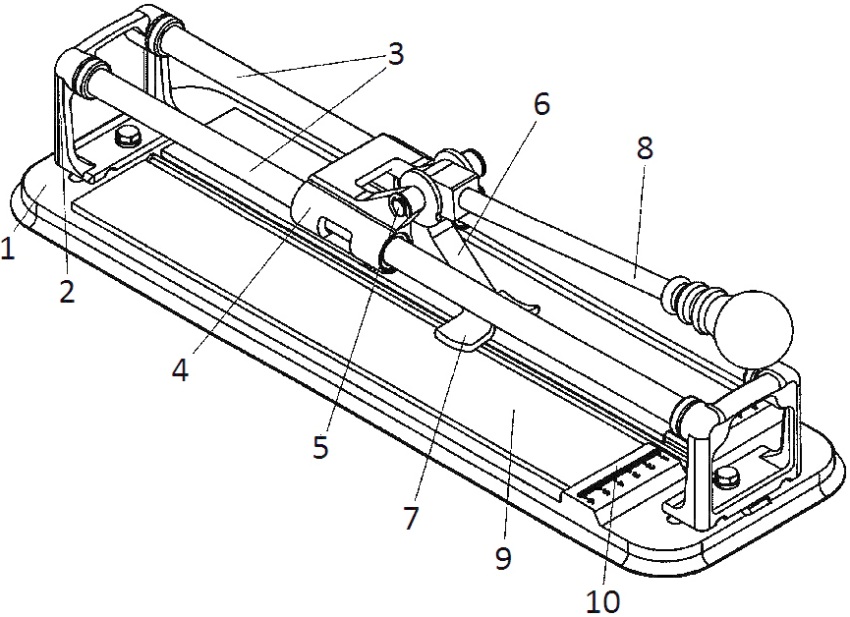

Manual tile cutter device: 1 - base, 2 - racks, 3 - guides, 4 - carriage, 5 - swing axis, 6 - rocker arm, 7 - breaking knot, 8 - control knob, 9 - substrate, 10 - measuring ruler

There are several ways to cut tiles or any other material. The cutting method is determined by the design features of the hand-held device. Let's consider these methods in more detail:

- holding risks (lines) followed by a break;

- biting off the edges;

- full cut.

Often, when laying tile material on the work surface, you have to face various obstacles (for example, protrusions or jambs).To bypass these obstacles, you must be able to correctly trim the tiles. And also often craftsmen are faced with such a problem as the presence of irregularities in places where the working surfaces touch. In such cases, you have to make bevels on the tiles.

Depending on the design, the tile cutter can make break lines, nibble edges, or completely cut tiles

The main functions that manual cutting devices perform:

- trimming the facing material;

- straight cuts;

- curly cuts;

- making various holes;

- organization of recesses;

- cut at an angle of 45 °.

Helpful information! In order to simplify the process of laying this or that material, experts advise purchasing multifunctional tile cutters equipped with various additional elements.

When choosing a fixture for one-time use, you need to pay attention to the characteristics of the tile, and professional models require a more careful selection. In any case, when choosing, it is necessary to study the main varieties and characteristics of devices.

Benefits of using manual tile cutters

The length of the manual tile cutter can be different (from 30 to 60 cm), and experts recommend purchasing longer models, since they are more versatile. The use of a tool that is 60 cm long allows straight and corner cuts in tiles to be made without much difficulty. Let's consider the main advantages of hand-held devices used for cutting:

- the main advantage of the handheld device is autonomy. This tile cutter does not require electrical energy to operate;

- low weight, which affects the mobility of the device and allows it to be used in confined spaces;

- the presence of auxiliary components, which include: a ruler, a square, and also a "ballerina". They are necessary to simplify the process of cutting the tile material.

Note! Devices equipped with a "ballerina" allow making round holes in the tiles for pipes.

The price of a tile cutter can be different and depends on its design features, component parts, as well as the manufacturer's company. For example, the cost of foreign devices, as a rule, exceeds domestic counterparts.

Varieties of manual tile cutters: professional and amateur

Depending on the complexity of the execution, all hand-held cutting devices are classified as amateur or professional.

Amateur devices include wire cutters and roller cutters. These are very simple devices from a constructive point of view, the cost of which is much lower than that of professional models. The use of nippers allows you to make shaped holes in the facing material, but they are not suitable for an even cut.

Roller cutters allow you to make a straight cut, but you need special skills to use them. Working with such a cutter involves the most real manual work, which requires some effort. Their average cost does not exceed 100 rubles, which is very profitable from a financial point of view.

In turn, professional tools are divided into two main types:

- mechanical;

- electrical.

There are two types of mechanical hand tiling devices:

- roller;

- bearing.

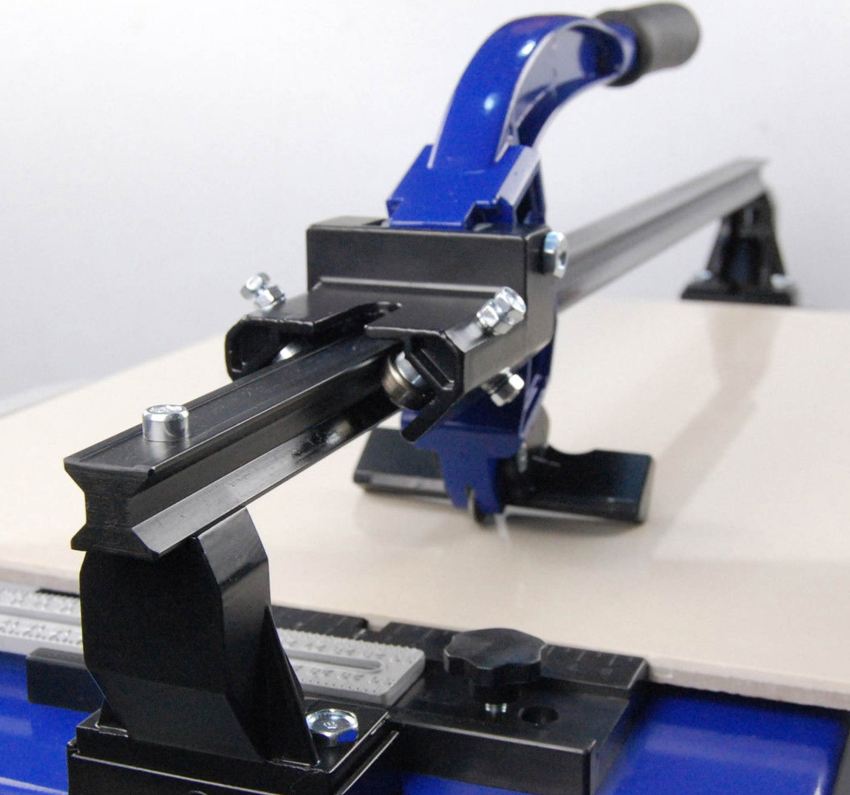

The device, which is based on a roller mechanism, is the most widespread and demanded in the construction market. This is due to the simplicity of the production of this device, as well as the fact that its operation does not require any special knowledge and skills.

Using the roller version of the manual mechanical tile cutter allows you to get a fairly accurate and even cut. This accuracy is achieved due to the presence of a rigid carriage in its design. Roller models are great for working with not only thin but also thicker hard tiles.

Bearing devices for cutting tiles are equipped with special bushings, which allow for maximum softness of the stroke when making a cut. Their use is recommended in the case when work with non-standard tile material is to be done.

Note! Typically, handheld cutters are used to cut material that is less than 15mm thick. However, it is sometimes necessary to cut a tile with a thickness of 16 mm. In such a situation, it is recommended to use a bearing hand model.

Electric hand-held models are more complex from a design point of view and therefore are used much less frequently.

Manual electric tile cutters

The design of electronic cutting devices differs from mechanical counterparts and has some peculiarities. The manual electric model includes the following structural elements:

- handle (for ease of use);

- sole, which acts as a support;

- special regulator of immersion depth and angle of inclination of the cutting element;

- cutting element.

An electronic device for working with tiles and other facing materials has one big plus - the ability to attach a dust collector. In the case when a "wet" cut is made, a special water tank can be connected to such a device.

It is important to remember that the cuts made with such a device are not of high quality. The main function of a manual electric tile cutter is to replace an angle grinder.

Manual tile cutters for porcelain stoneware

With the help of the electronic model, it is possible to cut fairly complex materials that mechanical tile cutters cannot fully handle. The main such material is porcelain stoneware. The difficulty of working with it lies in its high strength characteristics, which largely determines its purpose - laying on the floor.

Related article:

How to lay tiles on the floor: installation methods and technology features

The nuances of preparing various types of surfaces. How to grout tiles. Criteria for choosing a tile flooring.

Electric tile cutters for porcelain stoneware function according to the wet-cut principle. In turn, "dry" cut is not suitable for work with this wear-resistant material. Of course, mechanical hand tools can also be used, but this comes with some complications. For example, such models cannot cut a piece of this material if its width is less than 3 cm. Because of this, the edges of the tile material will have to be sanded.

There are other problems of a hand-held device that arise when working with porcelain stoneware:

- the problematic nature of the fault clearly along the cut line;

- the inability to perform a diagonal cut;

- the lack of the ability to use when crossing obstacles.

Electric models do much better when working with porcelain stoneware. They not only eliminate dust in the room, but also contribute to more accurate cuts of this material.

Manual tile cutter: price and review of popular models

Today, there are several of the most popular devices that are distinguished by high performance, convenience and reliability. Among them there are both manual mechanical and manual electronic models.

The best manual tile cutters that function mechanically:

- STAYER 3310-48;

- BISON EXPERT 33195-60;

- RUBI STAR-60-N.

The most popular handheld models that operate on electrical energy include:

- STANLEY STSP125-B9;

- STURM TC-9811.

Note! Mechanical hand devices are perfect for working with tiles in normal conditions (when renovating an apartment). Electronic, in turn, are less common and even rarely used by experienced professionals. However, in some situations, their use is the only possible option.

The tile cutter from each brand has its own advantages and disadvantages. Therefore, to select the required product, it is recommended to carefully study the characteristics of each tile cutting device. The prices of manual professional tile cutters are quite high, but such devices are much more reliable and have a long service life.

Features of the STAYER manual tile cutter

STAYER 3310-48 manual tile cutters are manufactured by a German company in China. The peculiarity of such a model is that it is excellent for making a figured cut. The size of such a device is 42 cm, which limits its capabilities. However, tile cutters of this brand are distinguished by the best indicators of functionality and low cost. The STAYER has a cutting depth of 16 mm, which is more than sufficient for normal finishing work.

This model has an additional element that allows you to make round holes in the tiles - "ballerina". The hole diameter ranges from 30 to 80 mm. Also STAYER 3310-48 is equipped with guiding elements, which are necessary for making a diagonal cut.

There are often devices on sale from this company that do not correspond to the declared quality. Therefore, when buying a STAYER 3310-48 model, you need to pay attention not to purchase a defective device.

The advantage of buying this model is obvious if you find out how much the STAYER 3310-48 tile cutter costs. The average price of such devices is about 1,750 rubles, which is very profitable from a financial point of view.

Manual mechanical tile cutter BISON EXPERT

Tile cutters of this domestic manufacturer are highly popular, as they are the best value for money. In comparison with more eminent brands producing these products, the ZUBR EXPERT 33195-60 device is much cheaper.

BISON EXPERT has a length of 60 cm, which allows it to be used for cutting long tiles. Also, its design takes into account the use of a built-in ruler, which eliminates the need for organizing preliminary marking.

The cutting depth of such a device reaches 30 mm, which is a very high indicator. BISON EXPERT 33195-60 is equipped with a carriage on bearings and has a comfortable handle. And also thanks to such a mechanical tile cutter, you can cut the tile material at an angle.

Of the shortcomings of this model, only one can be noted, namely the presence of a backlash (gap) in the roller. Such a minus can affect the accuracy of the cut. The cost of the domestic device BISON EXPERT is approximately 3350 rubles.

RUBI STAR manual cutter: model features

RUBI tile cutters are produced by a renowned Spanish company and are renowned for the best quality. The RUBI STAR-60-N model is one of the best examples of this manufacturer. In most cases, such tile cutters are used by professional tilers.

Helpful information! The base of the RUBI manual tile cutter has good strength characteristics and high rigidity. And well-fixed guides prevent the torch from moving freely when cutting.Thanks to this, the cut is almost always perfectly flat.

The RUBI STAR-60-N model has a set of interchangeable cutters for different types of tiles. Their thickness varies from 6 to 10 mm. It should also be said that this model is equipped with special plastic wings for additional fixation of the tiles.

Of the shortcomings, only one can be noted - a rather small cutting depth, which is a maximum of 12 mm. The average cost of a RUBI tile cutter is 7,500 rubles.

STANLEY electric manual tile cutter

A company from the USA is engaged in the production of these devices. The main difference between the STANLEY STSP125-B9 tile cutter is its low weight. The engine of this device is slightly more powerful than the competition, which is a small plus.

Separately, it should be said that the electronic model STANLEY STSP125-B9 has a large cutting depth (41 mm). Thanks to this, it becomes possible to work not only with ordinary facing materials, but also with rather massive slabs.

STANLEY STSP125-B9 can be used in both dry and wet cutting modes. The average price for such professional electronic devices is 3,500 rubles.

STURM manual electronic tile cutter

STURM models are manufactured by a Chinese company and have better functionality in comparison with competitors. The STURM TC-9811 model is a very compact device, which significantly increases its versatility and operational scope.

The main feature of the tool is that it is equipped with a system that cools the disc by means of water supply. This eliminates the possibility of tile overheating and deterioration. The cut made with this tile cutter is almost perfect.

Among other advantages of the TC-9811, it can be noted that its device allows you to make cuts at an angle of 45 °. And also it can be found non-standard application (as a chasing apparatus). Optional accessories for this electronic tile cutter include a second diamond blade and spare brushes. The average cost of the device is approximately 2600 rubles.

Where to buy a manual tile cutter: tips for choosing

A device for cutting tiles can be purchased at a specialized store, a construction hypermarket, or ordered on the Internet. In the latter case, there is the possibility of buying defective products, so it is recommended to be careful and not order tile cutters on questionable sites.

How to choose a manual tile cutter? There are a number of important factors to look out for when choosing a cladding cutter. Let's consider each of them in more detail.

Appearance... The visual component is important when choosing a tile cutter. Special attention must be paid to the base, which must be of high quality and durable. Its thickness should be sufficient for the convenience of working with the device.

Helpful information! When choosing a tile cutter, it is worth examining the lever and guide elements. For example, when cutting porcelain stoneware, a lot of effort is required, so the tile cutter in this case must have a long handle.

Length of the working area of the tile cutter... When choosing a tile cutter, it is necessary to take into account the diagonal length of the tile with which you will work. It is desirable that the length of the working area is not less than the diagonal of the facing unit.

Carriage travel on guide elements... During the operation of the carriage, its course must be smooth. In no case should it get stuck while moving or swing due to backlash. Bearings can be included in its design, which is an undoubted plus.

Cutting roller... The roller should not have any backlash, and its movements should be smooth.In case of failure, the replacement of this element should not be accompanied by difficulties.

How to choose a tile cutter depending on the purpose? If you need a reusable device for work, then you should think about purchasing a manual professional tile cutter. It is not difficult to buy such a device, and it can serve for more than one year. For a one-time use, a less expensive Chinese-made model is suitable. And for cutting 1-2 tiles, you can take an amateur model in the form of a pencil or nippers.

There are many materials on the Internet that will help answer the question of which manual tile cutter is better to buy. Reviews on relevant sites will also help you choose a tool.

How to use a manual tile cutter

In order to answer the question of how to work with a manual tile cutter, it is necessary to study in detail the algorithm of actions. Consider the process of cutting tiles in stages:

- The first step is to determine the trim size. It is very important to take into account wall gaps and seams.

- Guided by previously determined measurements, you need to place the ceramic tile on the bed of the cutting device.

- Next, you need to fit and align the tiles along the special lines.

- While holding the tile, it is necessary to draw along the cutting line with a cutting element.

- At the end, it is necessary to lower the legs of the separator on the handle and press (with force) the lever.

Knowing how to cut tiles with a manual tile cutter and performing all of the above steps in the desired sequence, cutting the material will take place without difficulty. Likewise, you can trim up to 1 cm wide.

The tile cutter is a functional building tool that can significantly simplify the work of laying ceramic tiles. For more efficient use of the device, we recommend that you read the various instructions on how to use manual tile cutters. Videos on this topic can also be easily found on the Internet.