Using drywall in the construction and decoration of premises of various types has led to its widespread use. Curly ceilings and the installation of partitions are far from the whole list of its purpose. If the latter can be done without resorting to numerous operations, then a metal profile will be needed to install a new wall. To facilitate and speed up the installation of new walls, a cutter for a metal profile for drywall will help.

Content

Purpose of the tool

Installing partitions and new walls requires a hand or electric screwdriver, screwdriver, and a variety of hardware. To get rid of time-consuming and unnecessary work will help a cutter for a metal profile, designed to fasten a plasterboard sheet with a metal rail.

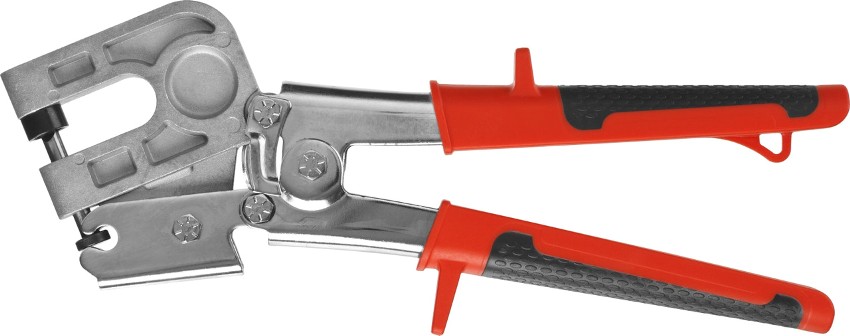

This tool is easy to use and does not require any special knowledge. Technically, its use resembles that of a punch or stapler. The robust steel of the functional part and the rubber handles of the metal structure divider make its use not only reliable and fast, but also pleasant.

The frame stitching device is produced in three basic modifications, such as:

- manual, making independent fastening operations, but its capabilities are minimal;

- reinforced professional divider with removable working elements, designed for a complex profile, due to a more perfect increased force;

- professional, uses multi-stage levers to transfer mechanical reinforcement to the working element - the punch.

The latter differs from the above-mentioned analogs in its high price and weight, it is used at construction sites, during major repair operations. It is somewhat difficult to operate.

The principle of operation of the profile cutter

The mechanism of action of the plasterboard cutter and its appearance resembles the work of tongs or pipe lever wrenches used when installing equipment. The working surfaces of the divider are two peculiar lips. A punch is attached to one of them, while the second plays the role of a stop, in which a recess is made for the diameter of the cutting element. The mechanism of action of the tool is quite simple:

- combine the parts to be mounted by superimposing one on top of the other;

- make a junction between the jaws of the tongs;

- bring the tool handles together sharply with effort.

By removing the divider from the metal rails, you can find a hole that fixes the part in the desired position. Depending on the type of a kind of countersink, the edges of the holes are bent and form interlocking petals, which improves the quality of the fastener. The thickness of the aligned strips varies from 0.55 to 1.5 mm, the hole diameter also depends on the interchangeable punches included in the kit - 2-5 mm.

Important! Before you buy a cutter for a metal profile for drywall, you need to know the thickness of the metal to be punched and the front of the upcoming work. This will reduce waste and save time.

Flashing advantages

The main advantage of the divider is that the fasteners are made without additional hardware - self-tapping screws. It takes a long time to screw in and out of the fixing screw if installed incorrectly. In addition, unnecessary operations threaten to turn not only the frame, but also the drywall into a solid sieve. At the same time, the sheet does not experience excessive pressure, therefore, any deformation is excluded, making installation quick and hassle-free.

The lack of a protrusion of the screw head also adds a big plus in favor of the divider, making the plasterboard fit more tightly. The tool of the mechanical principle of operation does not require power supply, making it indispensable in the absence or power outage during repairs. And wires running along the floor or cables located in the wall section pose some threat to life when installing walls or insulating walls.

Tool selection

The price of a cutter for a drywall profile depends, first of all, on its type: manual, reinforced or professional. Their comparative parameters are shown in the table below. It is necessary to take into account the intended purpose of the countersink, the type of proposed work and their volume. The brand of the inventory, the manufacturer, has an important role in the price. Of course, it is better to pay a little more for one high-quality splitter than to buy a second one instead of the first one that fell apart.

Purchasing characteristics of flashers:

| A type | Manual | Reinforced | Professional |

| Dimensions | + | + | — |

| Life time | — | + | + |

| Price | + | + | — |

| Popularity | + | + | — |

| Operability | — | + | + |

Dwelling on the above characteristics, we can draw the following conclusion:

- hand tools are popular among amateur craftsmen, their low price and external dimensions make them convenient at home when it comes to periodic installation or non-capital repairs;

- reinforced and easy-to-use, it will come in handy for a small team of builders engaged in the repair of apartments, other residential or utility rooms, its skillful use will allow you to forget about fastening screws for a long time;

- large-scale projects, capital construction, reorganization of the walls of the premises are only within the power of a professional profile cutter, which has several interchangeable punch holes and lips with recesses for them.

If the first two tools are attractive for their price and relatively small dimensions, then the latter has a long service life and versatility. But here it should be noted that it does not differ in the interchangeability of component parts. Up to the fact that some brands of diffusers are designed to work with the frame of the same manufacturer. Thus, before buying a cutter for connecting profiles, you need to decide on its type, functionality and intended purpose.

Note! The use of the tool does not require special training, but it implies compliance with the minimum safety rules.Before acquiring primary work skills, it is advisable to fasten the rails in cotton protective gloves.

Operating rules

The splitter of metal rails is a fairly easy-to-use inventory, but when working with it, it is advisable to follow some operating rules. For example:

- to create a good hole or high-quality fastening, it is necessary to use a tool adapted for a given metal thickness;

- it is undesirable to make sharp movements during breakdown, this leads to a poor-quality cut of the rail;

- it is prohibited to hit the tool jaws with a hammer to increase the breakdown force;

- the broach must be installed strictly perpendicular to the cut surfaces of the slats;

- it is impossible to make a breakdown of the groove at the joints or growth of metal profiles;

- the axles of the movable handle and roller must be regularly lubricated with a suitable oil or other plastic compound.

A careful attitude to the countersink will significantly increase its service life, simplify and speed up the work of attaching the gypsum board to the profile. Some masters treat the innovations of the renovation of premises with a bit of mistrust, preferring to carry it out using old-fashioned methods. The mentioned divider is no exception. However, it is unlikely that the reinforced screwing of the self-tapping screw, and then the same screwing out when its cap is torn off or the hardware does not enter the connected parts, will accelerate the progress of the repair. The main thing is to buy a cutter for a profile of a suitable type. This can be done at any specialized store.

Note! You should use a cutter for a metal profile for drywall only of those parameters that are intended for the breakdown of a certain metal thickness. Failure to comply with the rules of operation will lead to a shortened service life, its breakdown.

Cutter for metal profile for drywall: an overview of manufacturers

Construction specialty stores abound in various types of galvanized frame spreaders, brands of manufacturers. Like any tool, each of them has its own advantages and disadvantages. We suggest considering some trade marks of the instrument.

Knauf cutter

This construction equipment conveniently makes installation of galvanized rails for fixing gypsum board. The pliers make it easy to mark the material and check the fasteners. They allow you to hold drywall sheets vertically during installation of walls, transport them in this position and apply marking lines on flat surfaces.

The Shtantsange tool from Knauf is one of the most uncomplicated samples of a similar series, in fact, the model consists of only three elements:

- bracket with jaws and a fixed lever-handle;

- movable lever-handle equipped with a transmission device;

- firing pin.

The simplicity of the unit also allows it to be used as a plumb bob when installing slats on the ceiling. A constructive solution is added by the fact that the Shtantsange will withstand a tool bag, a screwdriver, and other tools suspended on it on the repairman's mounting belt.

Cutter KNIPEX

The German manufacturer of hardware has long established itself on the market with a positive side. The pliers are designed to fix the guides by means of a cut with a bend of the galvanized petals. They will help the home craftsman to carry out small repairs of premises without the use of screws and other fasteners, which will greatly increase the productivity of work, allowing it to be carried out with one hand.

This riveter is able to fasten not only the strips, but also sheets of metal with a total thickness of 1.2 mm, thanks to the special oxidized steel used to manufacture the piercer. The specific lever mechanism reduces the force during the punching of materials, thereby facilitating the piercing, and the multicomponent plastic covering the handles makes it easy to hold the divider in your hands. The tool is equipped with a metal loop for secure storage in a closed position, preventing spontaneous opening.

Related article:

Disc cutting machine for metal: product classification

Types of structures, their characteristics and features. Review of the best machine tool manufacturers. Comparative characteristics of prices.

Performance characteristics:

- thickness of the pierced joint - 1.2 mm;

- size - 250 mm;

- net weight - 675 g;

- producer - Germany.

Positive feedback from specialists and professional craftsmen only improves the characteristics of the stitcher.

Cutter MATRIX

This hardware will facilitate the work of a beginner or professional when fixing rack or ceiling rails during repairs. A constructive addition is the ability to cut, bend and shape the corners of galvanized profiles. Buy a cutter for a drywall profile of this company, and you will forever forget about self-tapping screws slipping out of your hands, screwing them in incorrectly, leading to an increase in unnecessary holes. The mentioned brand is distinguished by simple use of hardware, efficiency, acid resistance, long service life.

Performance characteristics:

- thickness of the pierced joint - 0.6 mm;

- size - 250 mm;

- net weight - 1.75 kg;

- punch - U8 tool steel;

- levers - ergonomic;

- levers cover - rubber;

- functionality - with one hand;

- producer - China.

The breakdown hole is characterized by a clean surface without burrs, the appearance of two petals bent to the sides, there are no dents on the surface of the fastened parts.

Cutter STANLEY

The American manufacturer STANLEY enjoys a well-deserved reputation among the manufacturers of various types of tools. The reinforced punch model of this company is no exception. Used for installation, construction, repair and redevelopment of premises. Designed for fastening U-shaped rack or guide frames for gypsum plasterboards.

The tool is equipped with a powerful transmission mechanism, movable ergonomic rubberized handles-levers allow you to hold it with one hand, which is very important when carrying out repairs alone. An important addition is the presence of a fixing bracket for secure storage in a compact non-working position.

Performance characteristics:

- thickness of the pierced joint - 1.2 mm;

- size - 240 mm;

- net weight - 730 g;

- product material - tool steel;

- working surface material - oxidized steel;

- covering - black varnish;

- levers cover - rubber two-component;

- functionality - with one hand;

- producer - USA, Taiwan, China.

The splitter is resistant to mechanical shock, acid and alkaline corrosion, thus increasing the service life.

Note! It is recommended to buy a cutter for a metal profile for drywall only in specialized stores of building supplies. This will protect you from counterfeiting and wasting money.

ZUBR cutter

A professional Russian riveter provides fast fastening of thin-walled galvanized strips 1 mm thick. It is used for installation works of capital construction and repair.A strong connection is provided by punching holes up to 1.5 mm in diameter, followed by bending the petals on the back of the frame without using self-tapping screws.

The tool is completed with a set of interchangeable punches of various diameters made of high-strength steel. Rubberized handles-levers prevent the hardware from falling out of hands during work. The zinc coating of the divider protects it from corrosion, which is especially important for working in damp and humid rooms.

Performance characteristics:

- thickness of the pierced joint - 1 mm;

- size - 250 mm;

- net weight - 800 g;

- coating - zinc;

- punch - U8 tool steel;

- levers - ergonomic;

- functionality - with one hand;

- producer - Russia, China.

Distinctive features of the riveter are its high wear resistance, long service life, and increased reliability. The special shape of the bracket for mounting in hard-to-reach ceiling spots only complements the positive qualities of the stitching device.

Diy profile cutter

Disposable household chores related to strengthening the rack or guide rails can be carried out with some types of mites, previously modified into the shape of a teether. The latter, like the pliers, is equipped with levers, a cutting edge, a spring and a swivel mechanism. To convert them into a stitcher for galvanized structures or thin-walled sheets, a sleeve must be installed on one lip, and a tool steel punch on the other.

Of course, a home-made divider will differ from an industrial one in some inconveniences, however, buying a specialized tool for a single use is also not worth it.

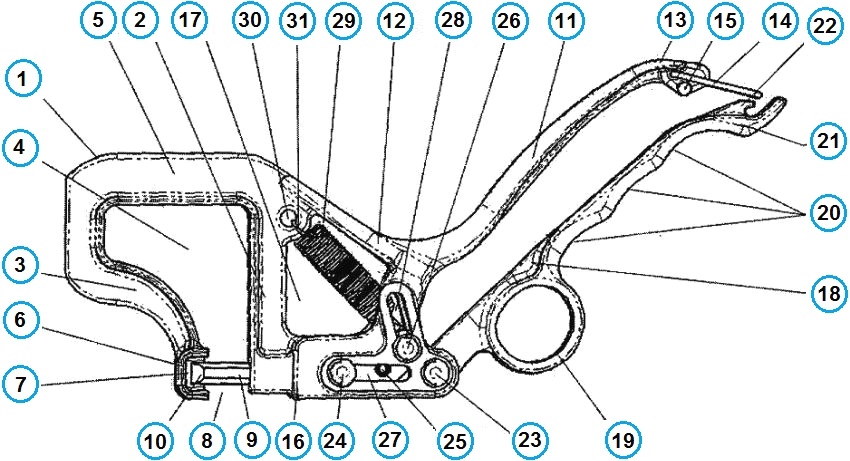

Profile cutter device: 1 - bracket, 2 - first leg, 3 - second leg, 4 - bracket opening, 5 - bracket base, 6 - stop, 7 - recess, 8 - working gap, 9 - punch, 10 - working end, 11 - fixed handle, 12 - fixed handle base, 13 - free end of the fixed handle, 14 - hinge, 15 - hinge travel stop, 16 - frame, 17 - frame opening, 18 - movable handle, 19 - ring, 20 - free end movable handle, 21 - hook, 22 - fixed axis, 23 - first movable axle, 24 - second movable axle, 25 - third movable axle, 26 - corresponding holes, 27 - second guide slot, 28 - rocker arm, 29 - first end turn , 30 - the second final turn, 31 - fastened parts

The cutter for metal profiles for drywall is an innovative working tool for the builder, repairman and home craftsman. Redevelopment or insulation of walls, a simple partition or a curly ceiling - everything is within the power of this firmware. With it, you will forget about screws, screwdrivers, and knocked down fingers.