The article discusses the most convenient and practical accessories for a garage with your own hands, which can improve the comfort of using this room. Here are detailed recommendations for the development and creation of structures designed for convenient storage of tools and car parts, advice on making furniture, as well as arranging lighting and heating systems.

Content

Useful DIY garage accessories: general recommendations

The garage is intended not only for storage, but also for car maintenance. For this reason, this room should be spacious, clean, comfortable and well-equipped.

To achieve all this, it is enough to take into account the basic requirements for the organization of space:

- The presence of shelves for tires and storage of tools significantly saves free space and allows you to optimize space.

- The quality of lighting is of great importance, since not only productivity depends on it, but also the quality of minor repairs.

- The construction of a garage workbench, machine tools, a viewing hole and other fixtures expands the range of possibilities for the car owner in relation to vehicle repair and maintenance.

Helpful advice! All these elements should not occupy more than 10-20% of the garage area.

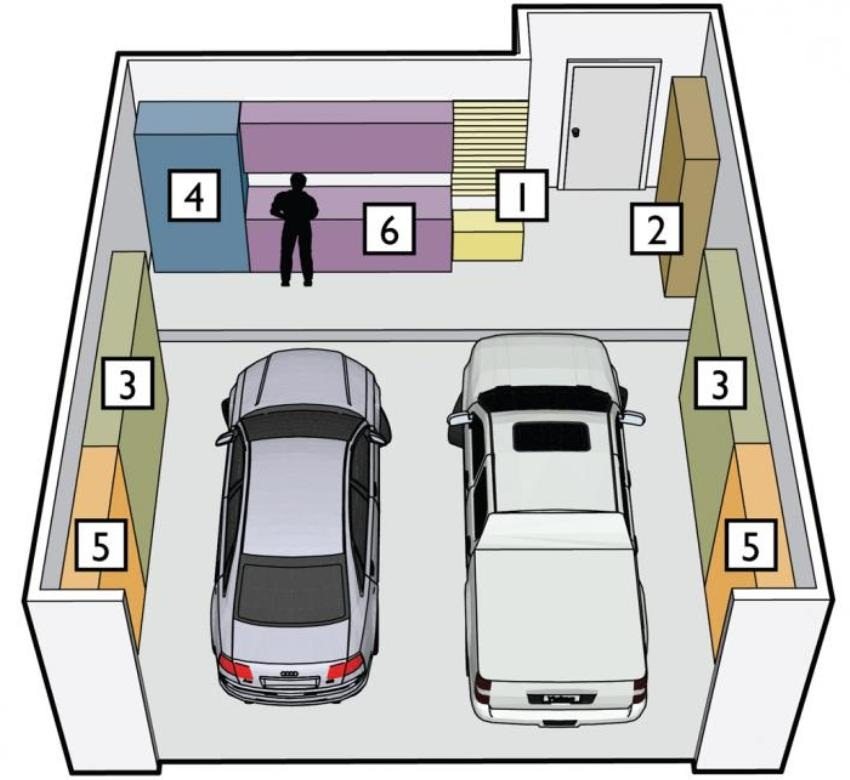

Optimal organization of the storage system in the garage: 1 - open brackets and hooks for frequently used tools, 2 - a rack for small tools, 3 - shelves for spare parts and tires, 4 - a rack for large tools, 5 - cabinets for various things, 6 - workbench with additional shelves

DIY garage shelf options: photos and tips for arranging storage spaces

About 80% of the shelves in the garage are self-constructed for storing garage accessories, namely:

- tools and accessories;

- component parts for the car;

- accessories.

Often, in the photo of shelves in the garage with your own hands, you find their combination with a rack, which you can also make yourself. Most often, the rack is considered as the main place for storing tools. After installing it, the remaining space is filled with comfortable and spacious shelves.

Be sure to allocate a place to store your work clothes. It is not necessary to occupy a large area, you can get by with one shelf or even a crochet (depending on your needs).

A garage is a place where hazardous and flammable substances are stored. These include oil, gasoline, solvents, paints, polishes. For them, it is necessary to provide a separate cabinet, hang a fire extinguisher and install a tank with sand.

To protect against contamination during storage of wheels mounted on tire brackets, it is worth purchasing large bags or specialized covers to prevent dust from entering.

Brackets and shelves for wheels in the garage: design features

The most bulky spare parts of a vehicle are sets of rubber, which can be winter or summer. When a winter version is used, summer tires are usually stored in the garage and vice versa. Therefore, you should organize shelves for storing tires or brackets.

The bracket design is as follows:

- Two triangular frames made on the basis of corners. Jumpers made of any durable metal are installed between these frames.

- The triangular parts of the structure are fixed to the wall at a pre-selected location. The wheels should be installed perpendicular to the support structure. In this case, the tires should fall slightly between the jumpers, thus fixing themselves on the shelf due to their own weight.

Helpful advice! It is recommended to place shelves for wheels in a garage with your own hands as close to the ceiling as possible at an optimal height. This prevents car tires from taking up useful space in the garage.

For compact storage of wheels, a whole rack in the form of four wide shelves can be used. It is suitable for placing wheels with disks that can be placed one above the other in a horizontal position. The structure can be made in a corner and raised on the wall.

To create a similar design, it is recommended to use:

- wooden beam;

- boards;

- chipboard sheets.

Installing tire brackets is the most efficient way to store your wheels. More space savings can be achieved by hanging rubber from the ceiling base along the garage wall. This option is possible if the room has a high height and reinforced concrete slabs on the ceiling. They will be used as a base for screwing in dowels.

Tool storage: interesting ideas for a garage with your own hands

To organize a convenient area for storing things, you can independently make a homemade and very spacious rack or shelves. Of course, you can find hundreds of ready-made models in stores, nevertheless, making a shelf in the garage with your own hands is much cheaper than buying a similar product on the market.

The problem is the same for shelving. Taking up the independent manufacture of storage space for tools, you can not only organize a convenient and practical rack, but also harmoniously fit it into the garage space.

Helpful advice! The minimum indicator of the loads that the structure must withstand is 150 kg or more. In this case, the maximum limitation of the load per section is 500 kg.

Rules for the manufacture of wood products:

- It is better to use hardwood such as beech, oak, hornbeam.

- Before assembly, wood must be treated with antiseptic agents.

- Frame parts must be carefully sanded to ensure safe operation of the rack.

- For the manufacture of shelves, it is recommended to use chipboard or plywood sheets, OSB. DVL plates with a thickness of at least 4 mm are also suitable.

The thickness of the material is determined by the loads that will subsequently act on the rack.

Recommendations for making do-it-yourself tool shelves in the garage

Shelves are installed in cases where the garage does not allow to put a rack. It is better if there are several structures.

Scheme for creating shelves for tools:

- Plan shelf placement, size and markup.

- Prepare the material in the form of boards and fasteners.

- Using a puncher, make holes in the wall, install dowels with hooks in them, which will provide enhanced fixation.

- Fasten hangers equipped with lugs on the boards. It is recommended to use self-tapping screws or regular nails for metal hangers.

- Fix the finished products using the building level, otherwise the tool may fall from the shelves, which makes operation unsafe.

Helpful advice! When making shelves, it is better to give preference to several short structures, since one long product can break under the weight of the tool.

At the final stage, you can make a decorative finish of the products (paint or special film).

Garage tool rack technology

To create a rack with your own hands, you will need boards 9 and 19 cm wide. The size of the structure can be adjusted.

Step by step technology:

- A 9 cm wide element is cut into several pieces 18 cm, 27.5 cm and 30 cm long. The resulting parts will be spacers.

- The board, which is 19 cm wide, should be cut into 36 cm long pieces. Shelves will be made from these parts.

- On the board, which will become the base of the product, it is necessary to apply markings in those places where the spacers will be. It is recommended to indent each side by 2.5 cm.

- The upper spacer is glued, then the upper shelf, which already has a spacer, is nailed to it. The rest of the parts are mounted in the same way. The bottom brace is installed at the end.

- Turn the structure over and tighten the spacers with screws together with the base of the product.

- The surface is thoroughly cleaned with sandpaper. After that, the product needs to be covered with two layers of oily varnish or another type of finish.

- The structure is fixed to the wall with anchor screws. Fixation should be done both under the upper and lower shelves.

Helpful advice! To strengthen the product, you should install wood blocks between the sections. They will allow you to evenly distribute the loads across the rack.

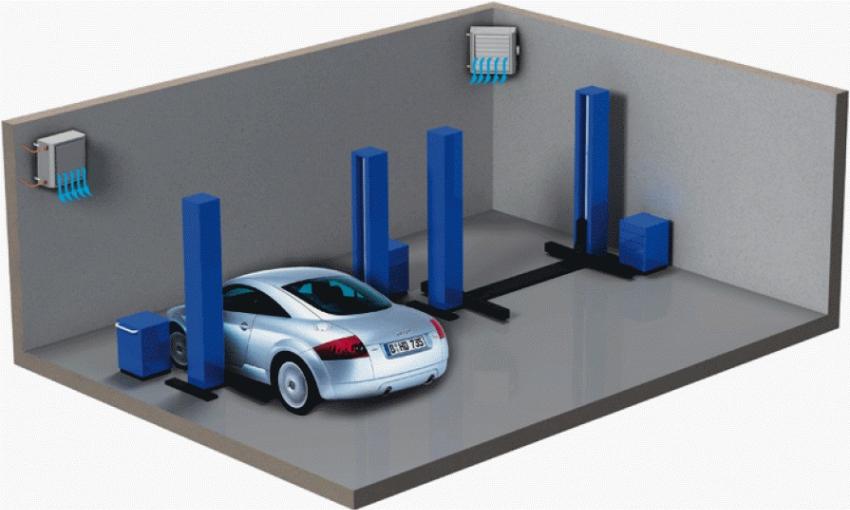

Organization of the lighting and heating system in the garage

In order for the operation of the garage to be comfortable, the lighting, ventilation and heating system should be properly organized in the room. Since cars are closely associated with the use of toxic and harmful substances, the problem of ventilation in a confined space is especially acute. For a garage, air vents are suitable for brickwork. They are equipped with grilles.

Factors affecting lighting levels:

- garage area, its height;

- the number and nature of the placement of working areas (dimensions of a workbench for a garage, inspection pit, number of machines);

- type of decoration on the walls, its colors;

- indicator of the specific power of the network per 1 m²;

- type of lamps for the garage.

Various types of heating can be used to maintain the optimum temperature:

- gas;

- based on used oil;

- air;

- electric (infrared heater for the garage);

- oven;

- water;

- solid fuel.

There are many alternative ways to organize your own heating system.

Features of halogen, fluorescent and LED garage lights

The technical characteristics of halogen lamps are in many ways similar to incandescent lamps, but their bulb is filled with bromine vapor, so the products emit more light. The advantages of such lamps include a long service life - 4 thousand hours.

Helpful advice! Products must be placed in shades. It is also worth considering stabilization, aimed at protecting against electrical surges. It is not recommended to touch such lamps with your hands (the shelf life is reduced).

The fluorescent lamps inside are filled with inert gases. From the inside, the flasks are covered with a specialized compound that emits ultraviolet light under the influence of an arc-type discharge. Recommended models include IP-65 rated products, protected from moisture and dust.

Installing LED lighting in a garage comes with the highest costs. Nevertheless, they pay off in 50 thousand working hours. In terms of efficiency, LEDs are 50% more profitable than fluorescent lamps. At the same time, they do not contain harmful components, and the light does not have an aggressive effect on the eyes, so there is no need to purchase plafonds.

Installing lighting in the garage: how to make a calculation

To calculate the power of conventional lamps, you can use the formula:

P = S x W / N.

Decoding of values:

- P is the total required power, W / m².

- W is the power of one lamp, W.

- N - number of lamps (luminaires), pcs.

- S is the area of the room, m².

For halogen and LED luminaires, the optimal indicator is 16-20 W / m². This value is suitable for rooms where the ceiling height is no more than 2.5 m. In garages with 3-meter ceilings, this figure should be multiplied by 1.5.

The calculation is influenced by the interior decoration of the walls of the room. In dark garages, the lighting should be brighter.

Light reflection level:

| Room area, m2 | Ceiling height, m | Wall decoration color | |

| Dark | Light coloured | ||

| 20 | less than 3 | 0,6 | 0,75 |

| 50 | 0,75 | 0,9 | |

| 100 | 0,85 | 1 | |

| 20 | 3-5 | 0,4 | 0,55 |

| 50 | 0,6 | 0,75 | |

| 100 | 0,75 | 0,9 | |

| 50 | 5-7 | 0,4 | 0,55 |

| 100 | 0,6 | 0,75 | |

To illuminate the inspection pit in the garage, it is recommended to use low-power lamps with halogen or LED lamps, since moisture accumulating in this place can provoke an electric shock. The devices are mounted on the sides in pre-made recesses.

Helpful advice! To prevent an accidentally falling tool from breaking the lamp, the design of the lamps can be made retractable. When the pit is not in use, the appliances are safely hidden in the recesses.

Do-it-yourself autonomous lighting system in the garage

There are a number of principles on the basis of which an autonomous lighting system is performed:

- LED strips are mounted inside the shades (there are 300 diodes per element).

- The output of the switch is carried out strictly on the shield.

- A suspended ceiling system is used for wiring.

- The wires are powered by a battery connected to the mains through a charger.

The multi-level lighting system for the garage is considered the most optimal.It involves the installation of a large lamp in the middle of the room and the installation of small lamps in the working areas.

Calculation of height for a multilevel system:

| Level | Height, m |

| 1 | ceiling base |

| 2 | 1,8 |

| 3 | 0,75 |

| 4 | 0,4 |

The luminaires are correctly installed if the machine does not cast a shadow on either side.

How to choose a heater for a garage

Garage heating is carried out using small portable devices that are able to warm up the room in a short time and further maintain the optimum temperature.

Thinking about which heaters are best for the garage, many people mistakenly believe that a home-made device can be made exclusively from expensive components and takes a significant amount of time. For this reason, garage owners give up this venture.

In fact, to make a garage heater with your own hands, it is enough to limit yourself to budget materials, for example, thermal film. The scheme for creating such a device is very simple and involves the use of the following materials and tools:

- a kit for assembling a heater;

- wires complete with a plug;

- paper laminated plastic (area of one element 1 m²);

- graphite powder;

- epoxy adhesive.

Helpful advice! Be sure to have a multimeter with you. When assembling the device, this tool is useless, but it will be needed to check for operability.

Thermal gas, diesel or electric gun - a common heating option in the garage

Recommendations for assembling a homemade garage heater

Step-by-step instructions on how to make a garage heater:

- A mixture of glue and graphite powder is made. The more powder in the composition, the stronger the heating of the device will be. The average temperature ranges from 60-65 ° C.

- The plastic sheets are coated on the rough side with a mixture of glue and graphite, which is applied in zigzag strokes, after which they are fastened with the front sides and fixed with a frame made on the basis of wooden slats.

- The terminals are fixed to the graphite conductors and the structure is dried. Drying must be complete, otherwise moisture will damage the device.

After the heater has dried, a resistance test should be performed. A garage heater is considered safe only after this check. Until this moment, it is strictly forbidden to connect the device to the electrical network.

Security restrictions:

- It is not recommended to leave the switched on device unattended or leave it near children.

- It is forbidden to use equipment capable of provoking a fire.

- Do not place flammable substances and materials near the device.

DIY useful garage fixtures

To carry out repair and service work, you will need to build an inspection pit in the garage with your own hands, the dimensions of which will correspond to the dimensions of the car, as well as a workbench for convenient work, plus equip the room with machines.

A basic set of tools and materials for creating a homemade garage workbench includes:

- boards and wooden blocks;

- fasteners and ties;

- planer and other tools for woodworking;

- varnishing and joinery adhesives;

- sandpaper and drying oil.

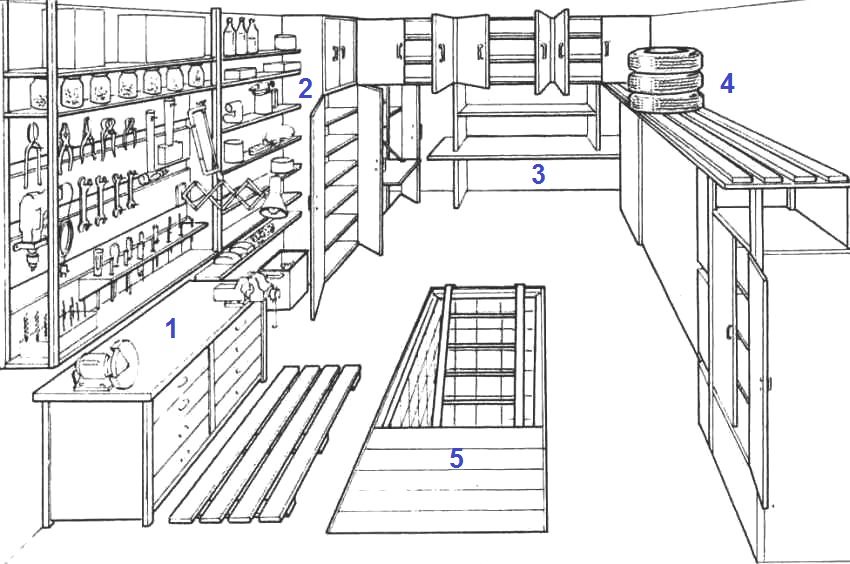

An example of placing useful devices in the garage: 1 - crafting table with manual machines, 2 - racks and cabinets, 3 - a table for various repairs, 4 - a shelf for storing tires, 5 - an inspection pit

DIY workbench manufacturing technology in the garage: photos, drawings

The workbench consists of a table top and underframe, as well as several clamping devices. The height of the workbench in the garage should be adjusted to suit your own height.You can take as a guide the height of the kitchen table in the house, at which it is convenient to work. Be sure to compose to create DIY garage workbench blueprints.

Helpful advice! Ready-made drawings of a garage workbench, which can be found on the Internet, are suitable as a basis for making a structure yourself. If desired, you can customize it to suit your needs.

Garage arrangement: how to make a workbench indoors:

| Stage of work | Details, size in cm | Mount type |

| Assembling the countertop | 20 boards (5x10x200) with 2.5x2.5 grooves in the 5th and 16th elements (step 25) | Adhesive composition of metal screeds |

| Drying | — | — |

| Making legs (4 pcs.) | Block (10x10x80) with slots for brackets on the front supports | Brackets |

| Assembling the base of the underframe | Frames (2 pcs.) Made of boards (5x10) | 2.5 cm spike and bolts |

| Fixing the side and rear support walls | Chipboard (thickness 10 mm) | Wood screws |

| Fixing the tabletop to the upper frame | — | Bolts |

Final processing involves impregnation of the finished product with linseed oil and opening with varnish.

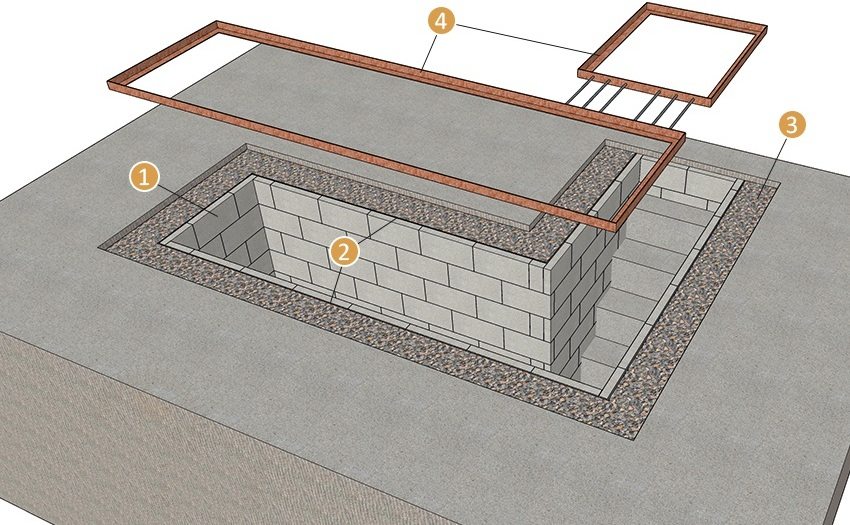

Recommendations for creating a viewing hole in the garage with your own hands

There is no specific size for an inspection pit in a garage. The dimensions of the car are taken as a basis.

How to make an inspection hole in a garage with optimal parameters:

- The width is selected so that there is enough space inside for work. The size is limited by the distance at which the wheels of the car are planted. Each wheel needs a small area to maneuver. The average pit width is 0.8 m.

- The length of the pit is limited by the length of the machine. To this indicator, 1 m should be added.

- The height of the garage owner is used to calculate the depth. Another 10-15 cm is added to it.

How to properly make an inspection hole in the garage using different materials:

| Material | Wall thickness, cm |

| Ceramic brick | 12-25 |

| Concrete | 15 |

| Building blocks | 20 |

The pit is pulled out taking into account the optimal width of the pit, the material chosen for the walls, as well as the thickness of the waterproofing layer. Stages of creating a pit:

- markup;

- pit construction;

- arrangement of the pit;

- construction of walls;

- lighting strip.

For waterproofing walls, a specialized hydrophobic impregnation is used.

Helpful advice! With the help of formwork, you can make reinforced recesses in the walls of the pit to accommodate tools and lighting fixtures.

Scheme of arrangement of the inspection pit: 1 - walls made of foam blocks, 2 - waterproofing, 3 - rubble masonry. 4 - corner 50x50x4 mm

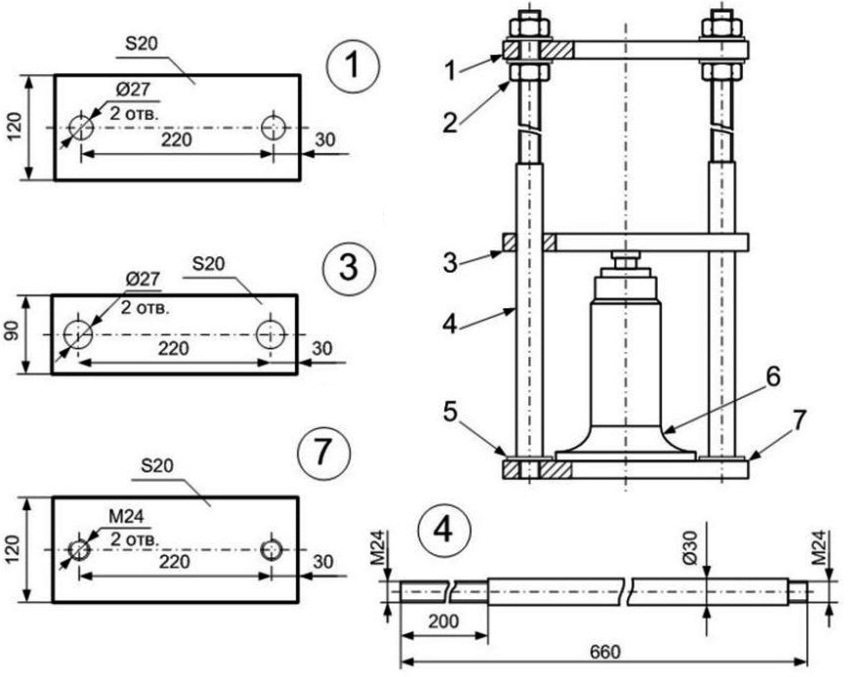

Making a press for a garage with your own hands

To create a press, a frame with a size of 178x80 cm should be made from 4 pieces of metal pipes. These elements are connected by welding. In the work, it is recommended to be guided by the drawings, selected in advance or drawn up. After that you need to install:

- retainer;

- removable emphasis;

- bottle jack (hydraulic).

You can use video materials to consider the detailed technology for creating useful accessories for the garage with your own hands. Such visual recommendations help you navigate in size, master step-by-step instructions and imagine what kind of appearance the finished structure should have.

Manufacturing scheme hydraulic press: 1 - upper power platform, 2 - nuts, 3 - lower platform, 4 - studs with a diameter of 30 mm, 5 - lower thread of studs, 6 - bottle-type hydraulic jack; 7 - base 20 mm thick

Garage arrangement you can do it yourself. The list of useful tools does not end there. It can always be supplemented with any interesting ideas. The main thing is that the garage fully meets the personal requirements for comfort and convenience.