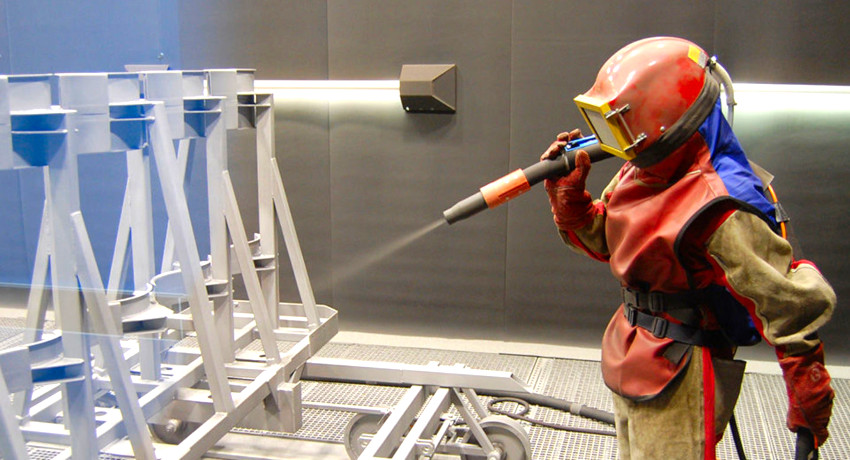

Before finishing the surface, it must be cleaned of dirt and old coating. Anyone who has ever prepared the walls for painting or removed the remnants of rust from the metal can imagine how much time and effort this process takes. If you do this manually, the result is not always satisfactory. Sandblasting machine - a device that polishes the surface with sand. Making sandblasting with your own hands is not such a difficult task.

Content

- 1 What is a sandblaster: what elements does it consist of

- 2 What you need to know about the principle of the homemade sandblasting

- 3 DIY sandblasting: types of devices and the advantages of self-production

- 4 What accessories are needed: how to choose a compressor for a sandblasting gun

- 5 How to start the process of making a sandblasting machine with your own hands

- 6 How to make sandblasting with your own hands from a gas cylinder

- 7 Do-it-yourself sandblasting from a fire extinguisher: a quick guide

- 8 How to install sandblast on "Karcher" and other alternative manufacturing options

What is a sandblaster: what elements does it consist of

Sandblasting is a device that delivers jets of sand under high pressure, which clean and polish surfaces. The use of the device allows not only high quality, but also quickly get rid of dirt or, for example, frosted glass.

The device is especially useful for small car repair shops, for owners who like to give old things a new look, as well as simply for owners of private houses where they constantly need to put things in order. The most convenient for work is considered a sandblasting gun with recirculation, which allows you to reuse the abrasive.

Fact! Of course, there is always the possibility of purchasing a ready-made device at the construction trading site. But the cost of the devices is quite high, and finding parts in the garage to make a homemade sandblaster with your own hands is inexpensive and simple.

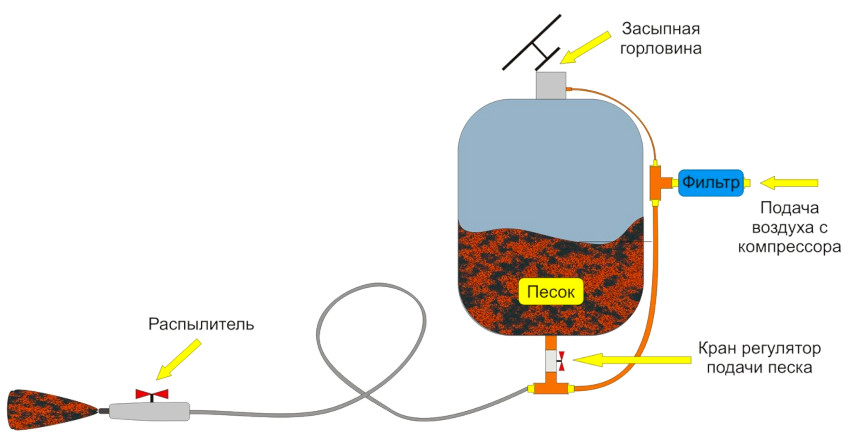

How to make sandblasting with your own hands? There are several ways.For this, 2 main structural schemes are used, the main difference of which is the mechanism for feeding abrasive sand at the output cycle. Despite this, both options require nearly identical parts to create meaningful knots. So, in general, sandblasting consists of the following elements:

- compressor - the main component that blows air;

- receiver - an element that is most often made on the basis of a gas cylinder;

- a small volume container - made from a fire extinguisher or freon cylinder, it is here that sandblasting sand is placed;

- a gun through which the abrasive will be supplied;

- connecting hoses.

All specialists who make homemade sandblasting machines focus on the fact that if you want the device to work longer, you need to equip it with a moisture separator. If it is a reciprocating compressor, the part should be installed at the inlet air supply to the oil filtration system.

What you need to know about the principle of the homemade sandblasting

Whichever type of construction is chosen, the device must form a jet of air-abrasive mixture at the outlet. The pressure system works due to the high pressure of supplying the selected abrasive to the outlet, where it mixes with the air flow coming from the compressor. If we talk about an ejector device, it is worth knowing that here the work is carried out using the Bernoulli effect, based on the creation of a vacuum, which sucks in the sand.

There are a huge number of schemes and do-it-yourself drawings of sandblasting machines that allow you to make them yourself. Every inventor prefers to use various unnecessary parts that are at hand, but all designs will work on a similar principle.

Before making a sandblaster with your own hands, you need to understand the mechanism of the tool, prepare all the necessary structural details. If you assemble the elements correctly, a homemade device will be in no way inferior to a serial one. It is often possible to design a device with minimal costs.

It is interesting! The principle of operation of sandblasting is very similar to the mechanism of action of a spray gun, the main task of which is to spray paint and varnish materials. However, one device can never replace another.

The main element that is needed for a sandblaster is a compressor. It is thanks to him that an air flow is created in the highways of the structure under the required pressure. As the air travels through the main hose through the sandblasting hose, a vacuum is created that causes the abrasive mixture to be sucked into the main line where it is connected to the air jet.

Then the mixture of air and abrasive reaches the nozzle - the hole through which the sand is supplied to the surface under high pressure. It follows from this that, in addition to the compressor, it is required to supplement the structure with hoses of the required diameter, connecting fittings, taps and dispensers. To provide uninterrupted power to the working device, you will need an electrical cable.

A sandblasting nozzle is an element that forms an abrasive jet with the characteristics required for work. You can make a ceramic nozzle with your own hands, because spent spark plugs are ideal for the base, from which the electrode is previously removed. On serial devices, there is a steel element with an internal boron carbide or tungsten carbide coating. In numerous user reviews, it is noted that such parts very rarely serve the owners for a long time.

DIY sandblasting: types of devices and the advantages of self-production

Before proceeding to creating sandblasting drawings with your own hands, you should learn more about the device itself and the main types of tools, as well as weigh the pros and cons of relatively independent production. In general, all devices can be divided into 3 large groups:

- Suction. Suitable for simple cleaning of surfaces. The principle of operation is extremely simple: air sucks in the sand from the container, after which the mixture is fed to the nozzle. This is the easiest homemade option.

- A device that works on the vacuum principle. The main advantage of a sandblasting gun with a recirculation of abrasive is the ability to reuse the substance that has escaped through the nozzle. In this case, the sand is re-sucked into the reservoir through a special chamber.

- Pneumatic sandblasting. The device is very powerful and delivers abrasive under great pressure. With the help of the tool, you can easily clean even the most dirty surfaces and neglected rusty parts.

Fact! It is recommended to use pneumatic sandblasting not only when it is required to process heavily soiled surfaces, but also if it is planned to clean a large area. Structures are often very complex, so they are rarely made independently.

Before making a sandblaster, you should study the advantages and disadvantages of such work. The advantages of self-manufacturing:

- with all the components and skills in assembling the tool, the creation of the device will not take much time

- there is an opportunity to save on buying a serial product;

- if you use high-quality components, the device is even more reliable than the factory version.

Among the disadvantages of self-manufacturing, the following nuances stand out:

- only a person with the appropriate skills can assemble the tool;

- if you buy low-quality parts, the device will not last long;

- An incorrectly selected and installed nozzle will not only complicate the job, but also reduce efficiency.

The use of high-quality components in the manufacture of a sandblaster with your own hands will ensure the reliability of the product

The main disadvantage is that if all the points are not taken into account during assembly, if the connections are assembled incorrectly or unreliably, then there is a risk of injury due to a ruptured valve or a reservoir with abrasive. If, before you start assembling the device with your own hands, consult with a specialist in this field, create a competent and detailed drawing under the guidance of someone who has already done such work, you will get a reliable home assistant.

What accessories are needed: how to choose a compressor for a sandblasting gun

The compressor is the most important part, because the sandblaster will not work without this element. Therefore, the choice should be approached deliberately, if only for the reason that the device is quite expensive.

It should be remembered that the performance of the device will depend on this component. Many do not advise making a sandblasting compressor with their own hands, the capacity of which is 500 l / min. It is optimal when the indicator is at the level of 700 liters. It must also be taken into account that this power must be maintained even at a pressure of 8 bar. The main elements affecting the ratio of pressure level and volume are:

- diameter of abrasive and air hose;

- material used to make the nozzle;

- line length;

- type and type of abrasive material.

An important criterion on which the choice and operation of the compressor depends is the nozzle diameter. The higher the indicator, the higher the pressure; the faster, respectively, it will be possible to clean the surface. You should also pay attention to the pressure indicators - it all depends on the type of material being processed.

The table shows how much pressure will be enough to process various surfaces:

| Surface type | Required pressure, bar |

| Concrete, artificial stone | 3-5 |

| Metal surfaces | 8 |

| Surfaces resistant to mechanical stress | 12 |

It is better to take a device with a certain power reserve, because it is not always possible to think in advance where you will have to use sandblasting, especially since you can make a device of any power.

The main types of compressors for sandblasting machine

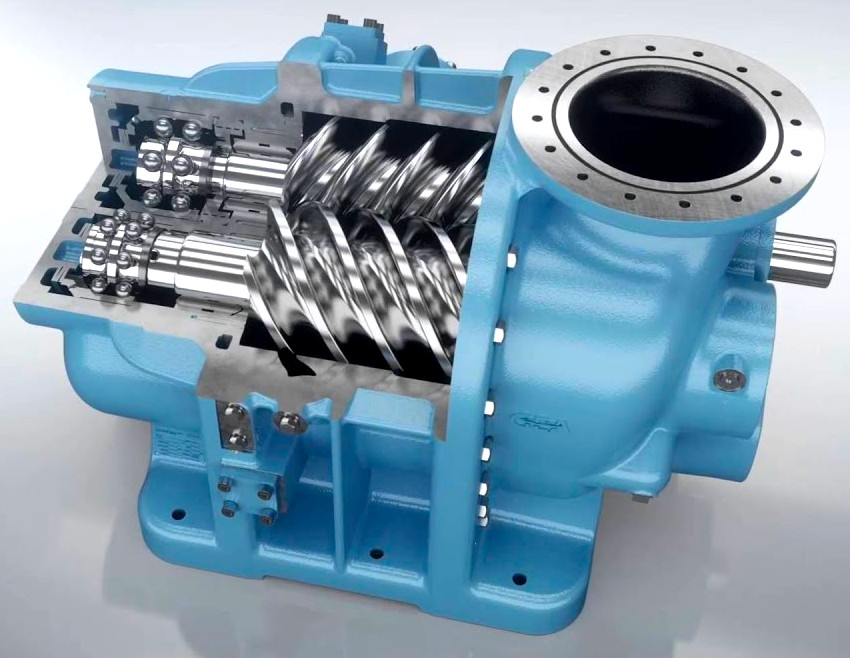

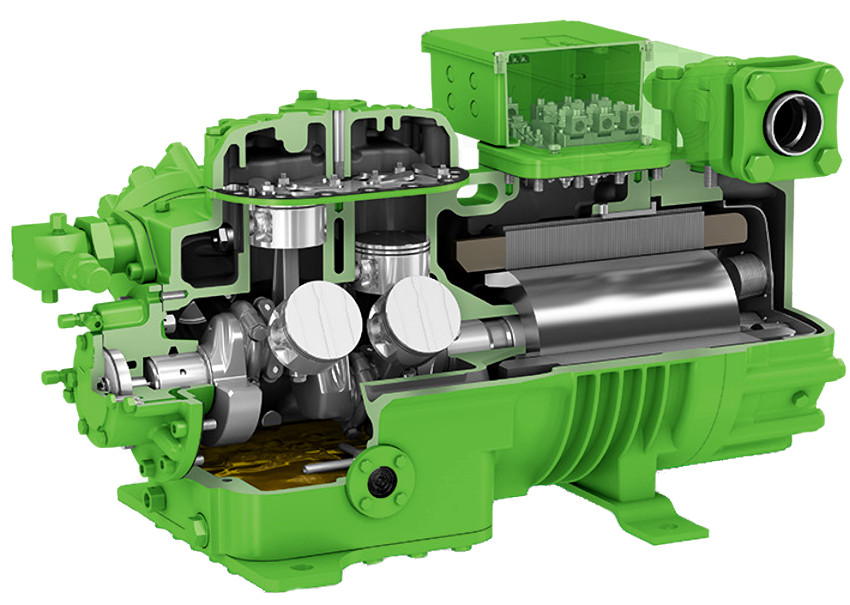

There are mainly 2 types of compressors used in sandblasting machines:

- screw;

- piston.

In most cases, when self-manufacturing, preference is given to piston options. These compressors are distinguished by high performance, but the air is supplied to the line with certain jerks. To eliminate this problem, an additional receiver is installed.

Some users also note that piston devices sometimes have problems with the oil supply. This leads to the appearance of moisture-oil condensation. The consequence of this nuance is the formation of lumps in the abrasive material, which may lead to the failure of the tool.

The principle of operation of a sandblaster with a screw compressor is somewhat different. Here, the device is based on 2 worm-type gears rotating in different directions. The main advantage is the absence of noise and unnecessary vibrations. For these reasons, if you plan to assemble a mini-sandblaster for home use, it is better to choose a screw compressor.

By the type of power supply, compressors are divided into diesel and electric. Each of the options has its own advantages and disadvantages. If you plan to assemble a small mobile device, it is better to give preference to the diesel version, the main advantage of which is the lack of connection to the 220 V network.

Accordingly, the device will be convenient to carry around the site, for example, to remove paint from a fence or gate. Another advantage of a diesel compressor is the ability to automatically control engine speed. This makes it possible to regulate and save fuel consumption.

The advantage of an electric compressor is lower fuel costs, but there is always a tie to the presence of an electrical outlet. It can be used at any temperature, while to operate a diesel device in frosty conditions, you will have to additionally purchase a cold start and preheating unit. Diesel mechanisms do not like low temperatures very much.

Related article:

Spray gun for water-based paint: varieties and tips for choosing

Varieties of atomizers for water emulsion. Rating of the best models. Recommendations for the selection and use of spray guns.

If you want to save as much as possible, you can make the device with your own hands using the available components. In particular, ready-made compressor heads are suitable for work, which are removed from the pneumatic brake device of such cars as ZIL and MAZ. You can often find them on old showdowns, at flea markets or on classified sites. For normal operation of the head, you will need to equip it with a receiver, as well as a frame for convenient attachment of other structural elements.

What parts are useful as components for making do-it-yourself sandblasting

Before making sandblasting, you should take care of the availability of the necessary parts, most of which can always be found in your garage, pantry or workshop. Missing items should be looked for at flea markets or in hardware stores. One of the important components is the tank, from where the abrasive sand will be fed into the pipeline. Most of the craftsmen prefer to use an old gas cylinder for this purpose.

Important! If a gas cylinder is taken for work, you should carefully look to make sure that there are no signs of rust, dents or other damage. In addition to using a cylinder as a container for an abrasive, it can be useful for making a receiver for a compressor, however, when disassembling, it is necessary to observe maximum safety precautions.

In order for the container to be freely filled with abrasive, it is required to weld a piece of pipe to the cylinder. For convenience, the neck should be fixed in the upper part, which will play the role of a funnel for filling the sand. You will also need other sandblasting equipment:

- Ball Valves. It is better to choose the most reliable and durable materials from trusted manufacturers with a good reputation.

- Reinforced rubber hose. The best option is considered to be a hose with a diameter of 14 mm, which is designed for high pressure and constant friction of abrasive sand.

- Gas hose. The diameter of the product must be at least 1 cm. It is through this hose that compressed air will be supplied to the system, which has not yet been mixed with the abrasive material.

- Collet type fittings and clamps. Needed in order to fix hoses to other elements of the system.

- Fum tape or other sealant. All connections require reliable sealing, because sandblasting works under constant high pressure.

Types and types of abrasives for surface treatment

The main consumable for work is an abrasive, under the influence of which the surface is cleaned. Sand taken from the river bank simply will not be suitable for this purpose, because it has a heterogeneous composition, and its particles differ in their size and shape. All this will subsequently affect the quality of the processed surface. In addition, large grains of sand during the cleaning process break and turn into dust, and the abrasive itself very quickly deteriorates, so it needs to be constantly updated.

First of all, you need to remember that only special types of abrasive are suitable for high-quality cleaning. Often this is not only sand, but also other suitable materials of artificial and natural origin. The choice of option will depend on the specifics of the work. The main parameters in this case are:

- hardness;

- the size;

- the form.

Interesting fact! In most countries, it is forbidden to use ordinary quartz sand for sandblasting, because quartz particles, when hitting metal, turn into dust, which can cause severe lung diseases. In addition to the impact on the health of the sandblaster, dust can harm others, even those who are far from the work site.

In general, the device of a sandblaster involves the use of such types of sand as:

- Plain river. The material must be sieved to obtain a homogeneous composition.

- Career. It is somewhat smaller than the river one, but, in addition to sieving, the material requires additional washing.

- Industrial quartz. Derived from ordinary sand, obtained by sieving and fractionating. At a cost 3 times more expensive than the river.

- Special crushed abrasive. Obtained by crushing quartz rocks. In this case, high efficiency is ensured by the acute-angled shape of the grains, which has a good effect on the surface.

What can be used, besides sand, to make a sandblasting chamber with your own hands

In addition to sand, other types of consumables are also suitable for the operation of the device:

- Nickel and copper slag. Some of the most popular options for sandblasting, which are obtained from copper and nickel production waste. The cost is the same as treated sand, but they are stronger and harder.

- Steel and cast iron beads. Not only the most expensive option, but also the most durable. It is used for fast but rough surface treatment.

- Pomegranate sand. Harder than normal sand, but just as fragile. It is expensive and rarely used for work.

- Glass and stainless beads. Sandblasted glass is mainly used for cleaning stainless steel surfaces.

- Electrocorundum. Solid crystalline form of aluminum oxide. Virtually indestructible and suitable for even the most dirty surfaces.

If you look at the photos of sandblasting, you can pay attention to the fact that the camera is a rectangular structure. Most often it is a box welded from a metal corner, which is sheathed with thin steel sheets up to 1 mm thick. In order to make it easier to control the amount of abrasive during work, it is best to place a glass or plastic viewing window on the long side.

On the front wall of the chamber, 2 symmetrical holes with a diameter of 100-120 mm are made, into which special thick gloves are inserted. It should be borne in mind that they will be constantly exposed to abrasives, so replacing these elements should not be difficult.

The bottom of the chamber is made of a reinforced mesh, under which there is a chute for the used abrasive. Lighting provides convenient work. To do this, it is enough to take 2 lamps of the required size. The sandblaster gun is placed inside the chamber and the air is supplied with a hose connected from the outside. Thus, the material will not fly out of bounds, which will make it possible to reuse it. In fact, this design option allows you to create a sandblasting gun with an abrasive recirculation system.

Helpful advice! If you plan to clean non-standard products of a large shape, it is advised to tighten the side edges with a strong tarpaulin. To make the camera as convenient as possible, you should not do work by eye - it is better to prepare a drawing first.

In addition to sand, nickel and copper slag, garnet sand, glass and stainless beads, as well as electrocorundum are used.

How to start the process of making a sandblasting machine with your own hands

The simplest thing that you can try to make on your own is a sandblasting gun. This option is a design with a handle, a tip and two fittings: one is used to supply compressed air, the second is to suck in sand into the system. If you plan to use the device intensively, it is still better to purchase a ready-made sandblasting gun. If the apparatus is supposed to be applied from time to time, it is quite possible to try to create a structure from the objects that are at hand.

To use the device comfortably, you should start by choosing a nozzle for your sandblaster. It is a nozzle through which a stream of air mixed with abrasive shoots. If you have the skills and the right tools, you can try and grind the part yourself, but most prefer to buy a ready-made element made of tungsten carbide or boron.On average, parts are designed for 100 or more hours of operation, while cast iron or ceramic elements are enough for 2-3 hours of operation.

Important! When buying or making a nozzle yourself, it should be borne in mind that the material must be designed for the effect of abrasive sand, which increases due to the high feed rate. For these reasons, the material is required to withstand mechanical friction.

According to the size of the nozzle, a sandblasting gun is produced, to which the fittings and the handle are then connected. The most primitive design is assembled from several fittings for water pipes, a tee, and a plastic sand tank.

In a simplified version, a cut plastic bottle, fixed in the upper part of the structure, acts as a container. This type of installation is easy to assemble in just a few hours. The work progress will look like this:

- sand is poured into the bottle;

- the gun is connected to the bottle;

- compressed air from the compressor is supplied to the gun.

How to make sandblasting with your own hands from a gas cylinder

On the network you can find a large number of videos "Sandblasting with your own hands", which show how to make devices from a gas cylinder. It is this design option that is considered not only durable, but also reliable. It is important to adhere to the instructions while working to avoid accidents. For manufacturing, you will need to use the following parts:

- gas cylinder for propane or freon;

- powerful compressor with a capacity of at least 500 l / min and a capacity of 3 kW;

- ball valves for regulating the supply of air and abrasive sand;

- a fragment of a threaded steel water pipe with a plug, which will be used as a funnel for the supply of sand, the optimal diameter is 2 inches;

- a tee with a thread marked "DN 15";

- rubber two-meter sleeve with a diameter of 14 mm;

- hose with a section of 10 mm, at least 5 meters long;

- 5-meter gas hose with a diameter of 10 mm;

- clamps and fittings for hoses, it is better to take with a margin;

- nozzle;

- sandblasting nozzle for the compressor;

- fum tape for reliable sealing and sealing of docking units.

The nozzle, as already indicated, can be purchased or made independently from an automobile candle or a metal bar. The main thing is to remember that 80% of the convenience and quality of work will depend on this detail: it is thanks to the nozzle in the sandblasting that the necessary pressure is provided.

In short, to make the nozzle, you need a piece of metal bar 3 cm long and 1 cm in diameter.The first 2 centimeters of length are bored to 2.5 mm, the remaining segment should have a larger diameter - about 6-6.5 mm.

DIY step-by-step sandblasting assembly: video

After all the parts necessary for manufacturing are prepared, they proceed directly to the assembly. First, you need to completely empty the gas cylinder. To do this, unscrew the valve and wait until the gas is completely released. You need to be extremely careful, because if you ignore this stage, then unpleasant consequences are possible. To be sure that the gas is completely out of the cylinder, it is recommended to insert the hose previously connected to the compressor. Then the gas mixture is completely pumped out.

After the tank is completely empty, you need to make 2 holes in it: one - at the bottom of the cylinder (1.2 cm in diameter), the second - on the opposite side. It is in the second hole that a 2-inch faucet will be installed. A pipe of the same diameter is also attached here. Then the following actions are performed:

- A steel tee DU-15 is welded to the bottom of the cylinder, where the sand will collect. The tightness of the connection will be ensured only by high-quality welding.

- For the stability of the structure, a tripod should be welded or wheels should be fixed. The second option will greatly facilitate the transportation of the device from place to place.

- After the completion of the work on the manufacture of the frame, they begin to fasten the small components. A fitting is placed on each thread, all functional units are sealed with fum tape. It is important to ensure that all connections are tight.

- Threaded bushings are mounted on the open ends of the installed tee. One of the nozzle outlets is closed with a 14 mm hose, and the other with a copper pipe 10 mm in diameter. A reinforced sleeve is attached to the copper pipe.

- A 14 mm nipple is connected to the valve on the cylinder. Then you need to take a 14 mm hose and fix it (using a collet clamp) at the cylinder, the other end is attached to a clamp to the tee.

- A sleeve is mounted on the remaining free end of the tee, which combines the tee mixer with a nozzle.

At the last stage, the compressor is connected to the mixer using a 10 mm hose, after which you can try to connect the unit and start operation. If it is necessary to increase the capacity of sand supply, an additional fitting is attached to the tank, the other end of which is connected to the compressor.

Do-it-yourself sandblasting from a fire extinguisher: a quick guide

When using a cylinder for a fire extinguisher, you get almost the same device as in the case of a gas cylinder, only of a more compact size. The disadvantage of this design is a small container for sand, which will need to be constantly refilled. Compact size and convenient transportation of the device are considered significant advantages.

Fact! It is much easier to make sandblasting from a fire extinguisher due to the fact that the valve is much easier to unscrew than in the case of using a gas cylinder.

As in the design from a gas cylinder, you will need to make a hole in the bottom of the fire extinguisher to fill in the sand. Then a threaded fitting is attached to the hole made. To give stability to the structure, it is recommended to weld metal legs to the cylinder. This trick will also help secure the bottom hose connection.

To create a complete structure, you will need to purchase a set of fittings and a crane. In general, the finished installation will look like this:

- a crane is installed at the exit from the cylinder from the fire extinguisher;

- on the left side there is an exit where the compressor will be connected;

- on the right, an outlet for the sandblasting sleeve is being prepared.

Also, to create sandblasting from a fire extinguisher, you will need to purchase a set of fittings and a crane

Then you need to connect a compressor to the device, and also install a sandblasting gun purchased or made by yourself. The resulting small device is considered ideal for small jobs.

How to install sandblast on Karcher and other alternative manufacturing options

Inventors who like to independently assemble tools from improvised tools or other devices suggest using a variety of materials in their work. Thus, they manage to produce devices of different types, for example, a sandblasting gun with a bag for collecting sand, which allows the abrasive to be used several times in a row, or various recirculation-type devices. At the same time, devices are often used in work that are intended for completely different purposes.

One good example is homemade pressure washer sandblasting. Most often, the equipment of the company "Karcher" is taken for work.As a result, it turns out to assemble a dust-free sandblasting machine that allows you to effectively clean even complex dirt.

Washing during operation creates high water pressure, while it is important that the liquid consumption is minimal. In order to get an efficiently working dust-free installation, you will need to assemble a sandblasting nozzle on the outlet pipe. In addition, you will need other components:

One of the options for homemade sandblasting is a device made on the basis of a high pressure washer

- homemade or ceramic nozzle;

- high quality reinforced hose;

- a mixing unit, you can use an ordinary tee, the main thing is to choose a part of the diameter you need;

- a feed control unit, which is a cylindrical dispenser;

- sand intake pipe, supplemented with an air supply path to a closed container with abrasive.

The finished water-type sandblast from the sink will operate on an ejector system. In this case, the high pressure water quickly passes through the mixing block and creates a vacuum in the abrasive feed unit. The sand is then thrown out together with the water under high pressure.

Among the features of using such a device, the following point can be distinguished: despite the low water consumption, the abrasive is fed very intensively. This allows not only cleaning the surfaces, but also matting the glass.

Helpful advice! In order for a device made from a pressure washer to deliver abrasive stably, fine sand with a uniform dispersion must be used. For household work, fine, sifted river sand is suitable.

With the help of a sandblasting made from "Karcher" you can not only clean surfaces, but also matte glass

How to make a tool from a blow gun and a spray gun

Another option is sandblasting from a blower gun, which is highly efficient, but small in size. The device is especially appreciated by car body work enthusiasts. The following parts are prepared for manufacturing:

- air blow gun;

- tee for plumbing work;

- ball valve, with which the supply of abrasive will be regulated;

- outlet nozzle with compression nut.

A lightweight fire extinguisher cylinder or even an ordinary plastic bottle is suitable as a reservoir for abrasive material. After connecting all the parts, the device is connected to the compressor.

Another popular manufacturing option is to use a spray gun as a base. In addition to him, other elements should be prepared:

- a handle equipped with an air supply mechanism;

- mixing valve, which is taken from the spray gun;

- container for abrasive;

- tee;

- ball valve regulator.

It is necessary to start work with the groove of the spray gun gun so that the nozzle of the required size can be used. After preparing the part, a mixing tee is connected to the gun. Hoses are attached at the end to provide inflow and circulation. The abrasive feed is started using the trigger button. The volume of a small tank is enough to clean small parts or surfaces for half an hour.

By following the instructions, you can create a powerful sandblast for large-scale jobs or make the device simpler. In this case, it all depends on the skills and parts that are available. Before choosing a specific design, it is better to immediately determine the scope of work that is planned to be solved using the device.