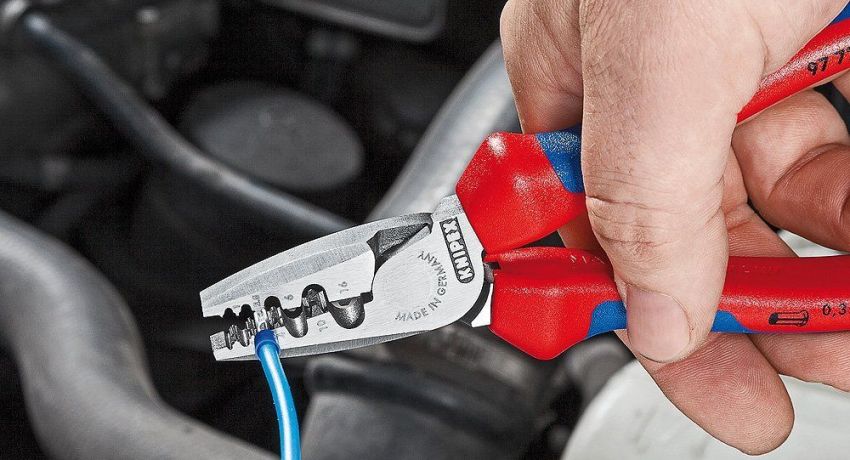

In order for the contact of the electrical wires to be of high quality and for a long time to contribute to the supply of electricity to the desired object, it is necessary to make the connection using the appropriate tools. The wire end crimping pliers provide sufficient connection area. It is only required to select the correct size of the matrix and consumables - tips and bushings.

For crimping the terminals, in order to fix them at the ends of wires of different cross-sections, use manual press tongs

Content

- 1 Crimping pliers: professional and household tools

- 2 Main types of lug crimping pliers

- 3 Methods of using crimping tongs for crimping terminals

- 4 Hydraulic crimping pliers for wire lugs

- 5 Crimper for crimping ferrules: design specifics, application

- 6 Varieties of ferrules for crimping stranded wires

- 7 Crimping pliers: how to choose

- 8 Do-it-yourself crimping of wire ends

Crimping Pliers: professional and household tool

Electrical is an area that requires impeccable compliance with the rules, adherence to precise technologies, and the use of special tools. Wire connections deserve special attention. Any inaccuracies and half-measures will necessarily lead to damage or rupture of contacts.

Crimpers are professional tools for electrical installation, and they are produced by many companies - manufacturers of hand tools

Twisting is a thing of the past long ago. They are strictly prohibited by the Rules for the technical operation of electrical installations of consumers. Today there is a special tool - wire crimping pliers. They consist of handles and a replaceable die, the selection of which must take into account the purpose of the connection and the cross-section of the cables.

According to technical features and method of operation, the pliers can be divided into two categories:

- mechanical (manual);

- automatic (driven by electric drives).

The division is also carried out within the categories. Mechanical pliers can be household and professional. With the help of household wires, wires with a small cross-section are crimped: 1-2.5 mm - copper; 2.5 mm - aluminum. It is possible to use a cable with a cross section of 4 mm to power powerful household electrical appliances.

The tool for crimping wires with a cross section of 6 mm or more is used by a powerful, professional. Thick power wires and cables in industrial installations are crimped automatically.

Crimping pliers handpieces are mechanical and automatic

Main types of lug crimping pliers

The need to use a crimp for wires can arise in two situations: in the case of preparing live parts for fixing various electrical appliances on the terminals and when connecting wires and cables. Depending on the purpose, one or another crimping tool is used. On the basis of design features, the pliers can be divided into two main types:

- functioning on the principle of pliers;

- diaphragm.

The first option is the most common. Pliers squeeze on both sides, from pliers they are distinguished by special recesses on the jaws, which allow making the connections as strong as possible.

The convenience of using this type of pliers is that you do not need to choose the position of the tips, you can perform the action from either side. Some problematicity appears in situations where the sleeve does not fit into the matrix. In this case, one more pliers are needed.

Useful advice! Before performing such electrical work, you must make sure that the dimensions of the tool and consumables are correct. As a way out - it is worth purchasing a universal model of pliers with a set of matrices that are fixed on a special cassette.

Diaphragm presses for wire lugs crimp sleeves from four or six sides, and they themselves adjust to the thickness of the cable. Crimping the end in this way is characterized by high density.

Crimpers are of a special kind. Although many call any crimping pliers that way, this article will apply the term to a tool for working with computer and Internet connections. The specifics of this device - further in the materials of the article.

Methods of using crimping tongs for crimping terminals

Work on crimping wires can be permanent or occasional. In everyday life, the second option is more typical. In such cases, there is no need to purchase a universal crimping tool for crimping wires. It is worth choosing a narrowly focused tool that will help solve specific tasks.

The main functionality of this type of tool includes:

- Crimping sleeves. The pliers required for this type of crimping differ in the shape and size of the matrix. A flange may be present as an additional structural element. Its presence will allow you to make a better connection.

- Removing the insulating layer. With the help of pliers, you can remove the required section of the insulating coating without directly damaging the core. It is important to set the correct size. If experience is not enough, it is better to purchase a tool where the size is set automatically. Such models are more expensive, but they provide quality work.

- Crimping tips. Presses for crimping wire lugs have a special rod, which is placed on the dividing seam during the operation. The device is designed to work with bare and brass wires.

- Work with twisted pairs. In such a crimping device, the wire is inserted into a special connector.

Only the right tool will allow you to make a quality connection.

Hydraulic crimping pliers for wire lugs

In the course of electrical work, hydraulic mechanisms are actively used. The main components of such pressing tongs are:

- pens;

- axis;

- head;

- matrix.

The head of the hydraulic wire lug crimping tool can be closed or open. With the closed version, the stopper is first opened, the matrix is pulled out, the wire with the sleeve is laid, closed, and only after that the crimp is performed.In an open-head design, no preparatory steps are necessary, so crimping is much faster.

Each model of hydraulic pliers is designed for a certain size range of wire cross-section. The maximum figure is 400 mm. In everyday life, such veins are not used, but it is convenient to work with a ferrule for wires for crimping with 6 mm hydraulic pliers. However, there is a danger of being pinched.

Manual hydraulic press for crimping cable lugs can have a closed or open head

Useful advice! For work with soft wire, it is better to purchase hydraulic press with a limiter. This will avoid overloading the tool.

In order to more clearly understand the consequences of pinching the hydraulic press, it is worth understanding the mechanism of its action.

Due to the swinging of the handle, the plunger (pump piston) makes progressive-return movements, a certain pressure is created, under the action of which oil enters the cylinder. The oil moves the cylinder, which, in turn, creates pressure in the matrix, and it acts on the sleeve with the necessary force.

Internet cable crimping tool

The stable operation of any cable system consists of several indicators. First of all, it is the quality of the material of the cable itself. This is followed by the professional level of the specialists who carry out the installation. The technical condition of the equipment matters. The quality of connections is absolutely unreasonable among the latter.

It is contacts that quite often cause unstable or weak signals. It is possible to avoid problems associated with unprofessional connections in the operation of the cable system only by using a special tool - crimping pliers, which are called "crimper".

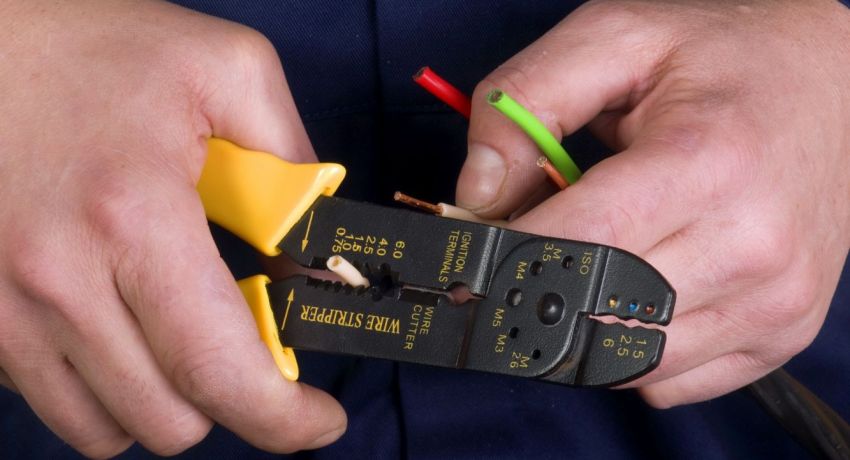

Any cable connection always starts with stripping the wire ends. For these purposes, there is also a separate type of tool called "stripper". With its help, the top layer is removed, there is no risk of damage to the core. Alternatively, you can purchase a crimper that has elements that allow you to strip. This is a hole with a blade on one side. By inserting the wire and scrolling it once, you can get the desired result.

Crimpers for crimping terminals and stripping wires are actively used by specialists in the installation of structured cabling systems.

Crimper for ferrules: design specifics, application

The principle of operation of crimping tools for crimping wire lugs is the same as for double-jaw pliers. The difference is that the latter clamp the sleeve, and the crimper - the plugs. More precisely, crimping is not performed in its standard sense, but a displacement of the contacts occurs, which leads to tight pressing. This tool is designed to work with twisted pairs.

Before crimping with a crimper, it is imperative to even cut the untwisted conductors. If this is not done, it will not be possible to achieve a uniform position in the connector, and this will affect the quality of the crimp. You can do this with ordinary wire cutters, but this does not always give the desired result.

Many internet cable crimping pliers are equipped with special wire cutters. They are blades that close tightly when you press the tool handles.

Important! Before cutting, the straightened wires must be set in the sequence required for connection (by color).

There are many varieties of crimpers. The principle of operation is the same for all models, but there are differences in the connector standards.On the body of the crimping pliers for cables, there are always symbols indicating the purpose of the tool. For example, RJ 45 is designated as 8P. This indicates the standard and the maximum number of pairs. RJ 11 - 6P, the maximum number of pairs does not exceed 6.

Crimping pliers for crimping cable lugs RJ 45

RJ45 connectors are among the most used in the field of computer networking. RJ stands for Registered Jack, a standardized network interface. The body of this device is much larger than RJ 11. The latter cannot be used for computer connections, it is used when laying telephone cables. The internal content and principle of functioning of these two types of connectors are almost identical.

Crimping pliers for RJ45 cable lugs are selected according to the designation. As for the general requirements, you should pay attention to the following indicators:

- Weight. A small one most likely indicates the use of insufficiently strong materials for the manufacture, so you should not count on a long service life. Excessively heavy ones will contribute to the rapid tiredness of the hands.

- The shape of the handles. It should be ergonomic and comfortable to grip.

- Defects. Traces of dents and other mechanical damage can be the result of improper assembly. It is worth paying attention to the contact line of the blades, sponges: even minor deviations will affect the quality of the crimp.

Hanlong HT-500 is among the most popular models of hand-held crimping tool for twisted pairs. The tool is designed for both RJ45 connectors and RJ11 and RJ12 options. The crimper is equipped with cutting and stripping blades. The price of the product is 1250-15000 rubles. The model should be classified as professional.

The inexpensive 5bites LY-T568R ticks are in high demand. They are also designed for three types of connectors, have blades. The products are lighter, weight - 340 g, less durable (according to user reviews in social networks). They can be purchased for 450-500 rubles.

Varieties of ferrules for crimping stranded wires

In the above article material, there is a lot of information about the tool with which the crimp is performed. But for the quality of the connection, it is equally important to choose the right tip. There are also several types of them. Let's dwell on products for stranded wires.

Related article:

Wire stripper: variety of tools

Characteristics, scope of use. Varieties of devices. Types of strippers. Popular models of famous brands.

Copper tips. Externally, they are a copper tube, flattened on one side, in which there is a hole for a bolt. Such tips are divided into uncoated (TM) and tinned (TML) elements. The latter are used in cases where it is necessary to make a connection with high anti-corrosion properties. Crimping wires with lugs of this type can be carried out with any kind of tongs, the matrix of which corresponds to the cross-sectional dimensions.

Copper with a test hole. This option cannot be crimped; soldering is used for the connection. Information placed for general information. Externally, the tips are similar to the previous ones, differ only in the presence of a hole through which the position of the conductors is visible.

Aluminum. Aluminum wires are crimped with ferrules of the same material. Outwardly, they are absolutely similar to copper ones, they are marked with MA.

Important! Before crimping, aluminum conductors must be treated with quartz-vaseline paste.It prevents the appearance of an oxide film.

Crimping pliers of this type can be used both hydraulic and manual.

Pin. With their help, permanent connections are made. They are designated by the abbreviation NSHVI - insulated pin sleeve tip. Wires stripped of insulation are inserted into a sleeve and crimped with pliers.

Ferrule for crimped wire: ring, hook, fork

To connect to the terminal blocks, you need to use lugs that will provide the most reliable connection. The main condition is that they must correspond to the type of this terminal block. Today, there are three main types of such tips:

- Ring. Their purpose is to connect to screw terminal blocks. Providing a large contact surface is one of the advantages of this type of tip. A similar option is used for temporary and permanent connections in low voltage networks.

- Hook type tips. They create a quarter less contact surface than annular ones. To crimp the electrical cable with this type of lugs and connect to the terminal, it is not necessary to completely unscrew the fastening screw. Such tips are more often used for temporary connections or in situations where it is impossible to unscrew the screw for some reason.

- Forklift. These tips have a contact surface that is 50% less than ring tips. It is for this reason that they are more often used for temporary connections when a constant change of contacts is required.

There are other types of handpieces, but they are specific and are rarely used, mainly by professional electricians when installing complex circuits.

Domestic tool: wire end crimping pliers KBT

Among the tools of domestic production, the press pliers for crimping the ends of wires KBT deserve attention. The main enterprise is located in Kaluga. The most popular are CTF kits, which include dies for crimping insulated and non-insulated ferrules, and CTB kits, which include numbered dies.

The CTB set consists of the following subject units:

- press tongs;

- 5 numbered matrices;

- plastic case.

The pliers are equipped with a mechanism for quick change of dies. High quality steel is used as a material for the manufacture of the tool. The press has a release lever. If the die size is incorrectly selected, the crimping process may not end, as a result of which the handles are locked in an intermediate position. In such cases, the tool returns to the starting point using a lever.

It should be noted that the handles of the pliers are elongated, which allows crimping with two hands. Five dies make it possible to select the option required for a particular tip type.

The CTF set also has 5 matrices. The tip crimper is not equipped with a quick-change tool, so a hex key must be used. The process of replacing the die takes quite a long time, sometimes even more than the crimp itself. The CTF kit (unlike CTB) has two additional screws for the dies in case of loss or damage to the used one.

Important! When inserting matrices, in order not to make a mistake, you need to pay attention to the size of the slot: the large one goes towards the handles, the smaller one - towards the head of the ticks.

Wire end crimping pliers: how to choose

In the variety of terminal crimping pliers offered by the manufacturers, it is quite easy to “get lost”.Product descriptions in online stores are full of positive characteristics. The following tips will help you navigate and choose the right tool model:

- The choice should start with a clear definition of the tasks. It is on the basis of them that it is necessary to select the size and functionality of the press tongs. If repeated crimping, stripping and cutting wires are coming, it is worth purchasing a universal version of the tool.

- For crimping and connecting cables with a large cross-section, it is more convenient to use a hydraulic mechanism.

- The important criteria are the price and the manufacturer of the tool. Verified brands are always more reliable. Low cost is likely to be an indicator of fragility in use.

- When buying, you should definitely check the pressing tongs for crimping the tips for defects and assess the build quality: using a visual inspection, identify possible dents and chips, check the correct contact lines of the blades, the position of the handles.

- Be sure to pay attention to the shape of the handles. The presence of the grip recesses helps to hold the tool more securely.

- It is recommended to hold the pliers in your hands. Possible inconveniences associated with shape and weight will certainly appear.

Among the vast assortment of crimper tools on the market today, everyone can easily find a tool for their profile.

Do-it-yourself crimping of wire ends

In theory, crimping wires is not a difficult process. A tool, appropriate consumables and some physical effort are all that is needed. In reality, connections can be poor, and sometimes you even have to repeat the procedure. This sequence of actions when crimping wires will be useful to those who are ready to do their own termination:

- It is necessary to process the cable, remove the insulation using a special device, leaving a margin of 0.3 - 0.5 cm. If the stripping was nevertheless done with a knife, make sure that the core is not touched. If damage is found, the area will have to be removed.

- Slide a piece of thermal insulation over the wire. Wipe the open part with alcohol, degrease and apply a special paste on it.

- Set the required section size and tip type in the matrix. Insert the tip to the end.

- The cable cores in the straightened state should be laid all the way into the lug.

- Press the crimper knobs. After a characteristic click, the compression can be considered complete. The handles should return to their original position.

- Return the section of the braid to the junction, warm it up with a construction hairdryer.

There is an opinion (and some do) that crimping is easy and without special tools, using ordinary pliers. To a certain extent, this is permissible, but only for wires of small cross-section and, if necessary, make a temporary connection. A snug fit of the ferrules to the core can only be ensured by the matrix. And then the ingress of air, water, metal oxidation is excluded, the connection functions for a long time and reliably.