The construction industry does not stand still. Manufacturers strive to produce improved materials and offer new technologies that can not only reduce construction costs, but also improve the technical performance of the final product. One of the latest developments, which originated in Sweden, is the USP foundation - a technology for the economical and fast construction of a foundation for a private house or a two-story cottage.

A monolithic foundation made of insulated Swedish slab is a great alternative to the traditional slab foundation

Content

- 1 Varieties of slab foundation, their characteristics

- 2 What is UWB: areas of use

- 3 USP foundation structure: sectional photo of the product

- 4 Advantages and disadvantages of USB foundation

- 5 Useful tips for base construction

- 6 Survey work, UWB calculation and terrain tracing

- 7 List of required materials and tools

- 8 Excavation and drainage

- 9 Layout of utilities and creation of an amortization cushion

- 10 Installation of a heat-insulating layer for the USP foundation

- 11 Reinforcement of the foundation of the Swedish slab and installation of a warm floor

- 12 USP foundation: technology for concreting the base

Varieties of slab foundation, their characteristics

Currently, there are three types of slab foundations, each of which has its own distinctive features. The Russian version, which was designed by domestic designers, is considered traditional. The product is a thick monolithic reinforced concrete slab with massive ribs. The foundation is characterized by a large strength reserve, no deformation, due to which it can be used under extreme operating conditions.

The disadvantages of the design include insufficient insulation and the need to pour concrete two times: the first - to create stiffeners, the second - to form the slab itself. However, this increases the period of operation.

The foundation in the form of an insulated Finnish slab comes from Finland. The structure is thinner, but it is characterized by sufficient strength. It is well insulated and adapted to the underfloor heating system. This foundation is a cold contour. Thermal insulation with a thickness of at least 150 mm is mounted on a slab, cutting off the cold basement contour from the warm floor of the first floor of the building, which is installed in an additional reinforced screed.

The insulated Swedish stove is less energy efficient, but more economical in comparison with the Finnish option.USHP does not need additional screed, since the underfloor heating system is mounted directly into the slab, the thickness of which reaches its minimum size.

What is UWB: areas of use

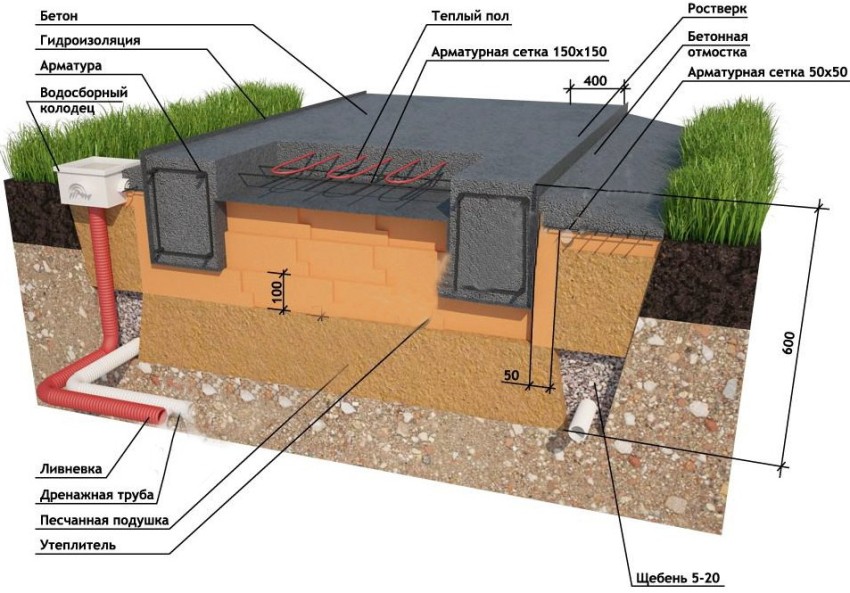

The insulated Swedish foundation slab is represented by a shallow monolithic slab foundation. It has insulation along the entire perimeter and sole area. This is a finished rough ground floor surface with built-in underfloor heating and utilities.

The high strength and heat resistance of the USHP foundation make it possible to use it in difficult climatic conditions for buildings made of any material

This type of foundation is used in building projects without a basement and basement. The USB technology is advisable to use for structures with a side size of 15 m in such cases:

- for cold regions, where, thanks to such a foundation, heat loss from the house is reduced;

- in areas with high groundwater levels;

- in private house projects where underfloor heating is used;

- in case of application fachwerk technology, as well as in the process of creating a panel, panel or frame house;

- when choosing block or brickwork;

- on heaving and weak soils that are not characterized by good bearing capacity, which requires the construction of bored or screw foundations.

USP foundation structure: sectional photo of the product

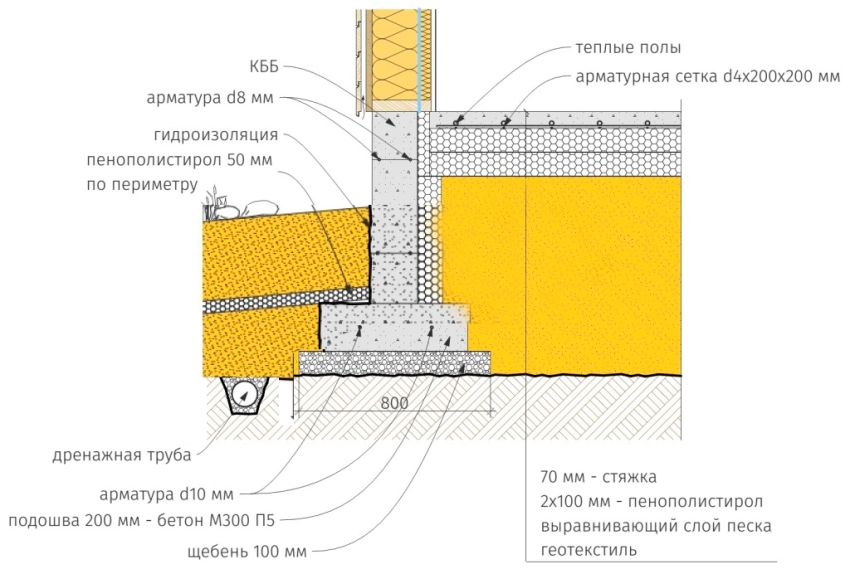

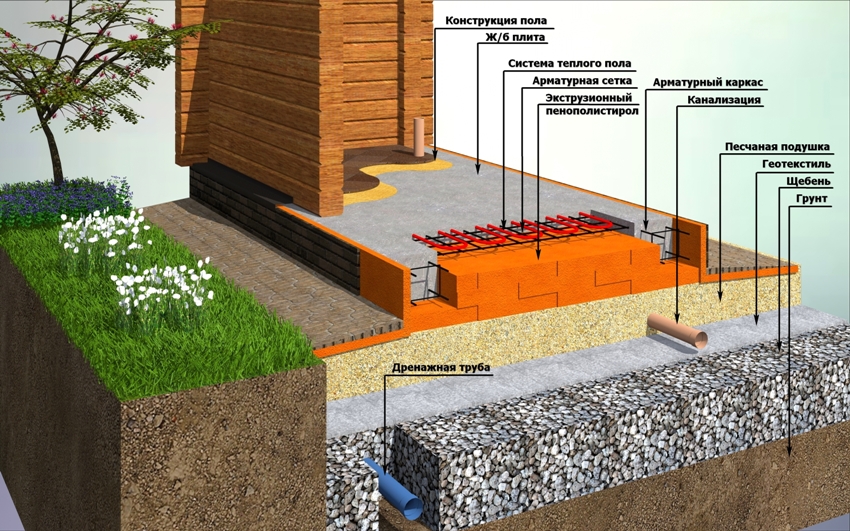

The structure consists of the following layers, which are clearly shown in the drawing of the Swedish foundation slab in section:

- concrete pouring;

- reinforced layer;

- depreciation layer;

- insulating layers.

Concrete pouring, or monolith, is represented by an ordinary foundation with a thickness of only 10 cm, due to which the structure is created in one day. This has a positive effect on the quality of the slab, namely: layering is eliminated and the cost of work is reduced. In this layer, a floor heating system is laid. The base is insulated from the ground with a heater, which is represented by extruded sheet polystyrene foam.

Reinforcement is also carried out in a short time due to the use of a small amount of metal rods. Tightly connected reinforced mesh prevents cracking of concrete, excludes damage to the foundation during natural movement of the ground.

The traditional layer of depreciation, consisting of sand and crushed stone, which is used in a conventional foundation, is complemented by this UWB technology with a layer of clay. Thanks to this, the geotextile laid between the mineral layers is not exposed to moisture. An additional waterproofing layer in the foundation is necessary in order to protect the structure from the influence of groundwater, which can erode the layers. In the thickness of the sand, under a layer of insulation, sewerage systems and a water supply system are installed, the nature of which affects the price of the USP.

To create a durable and solid structure, it should be equipped with insulation, so that the foundation will not crack and heave during temperature fluctuations. The process is carried out using styrene derivatives, as a result of which the service life is increased several times. The insulation is laid not only from below, but also vertically along the perimeter of the slab, duplicating the base formwork. Also, the layer is located under the blind area of the building horizontally at the depth of the base of the reinforced concrete structure. This technology increases the cost of UWB, but reduces further costs for heating the premises.

Drainage communications are necessary to create a system for removing moisture from the foundation, which prevents it from damage. A waterproofing layer with vapor barrier properties protects the concrete from moisture.

Advantages and disadvantages of USB foundation

The USP foundation, which can be ordered from any large construction company, is characterized by a number of distinctive advantages:

- low cost of work, which is associated with a small amount of construction materials and the involvement of a small number of workers;

- high speed performance;

- thanks to an additional layer of insulation, the probability of freezing of the soil under the base of the foundation is excluded, which will save the slab from heaving and shrinkage of the base;

- the base slab is a full-fledged sub-floor on which tiles can be laid without prior leveling the surface;

- arrangement of underfloor heating in the foundation will reduce the cost of heating in the future due to the lower consumption of thermal energy;

- the insulation is characterized by high compressive strength and shrinks the building by 2%;

- the thermal insulation layer is not affected by moisture, which increases its service life;

- due to the fact that the foundation is insulated, dampness and mold will not form in the house;

- the appearance of insects and rodents is excluded in the insulating layer;

- a small thickness of the heat-insulating layer provides the required thermal conductivity;

- the presence of edges on the thermal insulation plates excludes the creation of cold bridges;

- the plate performs simultaneously heating, heat-insulating and load-bearing functions;

- has the durability of the structure while maintaining all the technical and economic characteristics;

- due to its high heat capacity, it can be used in regions with cold climates.

Disadvantages of USWB:

- the foundation slab is created exclusively on a reliable foundation, which excludes its arrangement on silty, peaty or vegetative soils;

- a significant part of utilities is located in the thickness of the slab, as a result of which access to them is limited;

- USHP cannot be used in the construction of heavy multi-storey buildings;

- the foundation excludes the creation of a basement in the house.

Useful tips for base construction

The Swedish foundation consists of several layers, each of which has an important functional purpose. It is very important to properly organize each layer in order to obtain a reliable, strong and durable structure as a result. There are important points to consider here. The thickness of the sand or gravel substrate is determined based on the type of soil, that is, it depends on its bearing capacity. This value is in the range of 300-600 mm, which affects the price of the USB foundation. For the most solid, dense soils, the minimum indicator is used, and for heaving soils, the maximum.

USHP is a combination of a strip base and a concrete floor, which is why this type of base requires accurate calculations and adherence to clear technology during construction

Before building a slab foundation, remove the topsoil. With the help of a level and a building level, the verticality and horizontalness of the surface is checked. The pit must be larger than the perimeter of the slab. For this purpose, it is necessary to retreat from the edges of the base marking by 50-70 cm on each side.

Plates of insulation material should be laid over the entire surface of the foundation. It is not recommended to fasten them with additional adhesive. To create a uniform dense layer, the concrete must be poured in one go. Therefore, it is important here to correctly calculate the amount of material required to fill the formwork.

Useful advice! The best option for a USP device is considered concrete of class B20-B25.

Before starting construction, pipes should be prepared for all communications and a diagram of their location should be developed.Around the perimeter of the foundation, it is imperative to provide a drainage system, thanks to which moisture is removed from the base of the building.

Survey work, UWB calculation and terrain tracing

Exquisite measures precede the start of construction. They are carried out in order to determine the nature of the soil and its bearing capacity. The groundwater level of the area, the composition of the soil and possible fluctuations of the lower layers of the soil are being specified. These indicators must be as correct and accurate as possible in order to provide a solid foundation later. Therefore, here you should use the services of specialists.

The main difference in the calculation of the insulated foundation slab is the sequential determination of the parameters of each layer during construction, taking into account the actual loads and impacts. For this, special computer programs are used that determine the individual characteristics of the foundation.

Useful advice! It is better to design a Swedish foundation with the involvement of professionals, which will avoid many errors in the calculation.

After carrying out all the preparatory measures, proceed directly to the construction of the foundation. To do this, you should mark the territory, which is the application of full-scale axes. On the ground, the contours of the pit are outlined, castoffs are installed, along which the cords necessary for the installation of the formwork are pulled. The main advantage of overhanging (compared to conventional pegs) is a convenient U-shaped design, the position of which is leveled once in the horizontal plane. If the cord can be temporarily removed if necessary, no adjustment is required once it is reinstalled.

Before laying the foundation, survey work is carried out, which are aimed at determining the type of soil, its bearing capacity

The pit should be planned larger than the foundation slab. Leave an allowance of about 1 m on each side. Such indents will be used for installing drains. It can be an annular drainage to lower the groundwater level or wall drainage, used to drain the upper water, which is formed with the constant accumulation of rain and flood waters of the underlying layer in technogenic zones.

Related article:

How to build your own house with your own hands and how to do it cheaper

The main stages of construction, important nuances. Budget projects based on various materials and the right ways of saving.

List of required materials and tools

Do-it-yourself UWB is not as difficult as it seems at first glance. Before starting work, it is necessary to have a project for a new building and determine a place for construction. You can, of course, use the services of specialists and order a turnkey UWB foundation. However, strict adherence to technology and the use of quality materials will independently create a solid and reliable foundation for subsequent construction.

Before pouring concrete, it is necessary to prepare a flat area and properly tamp it with a special machine

The list of materials required for the construction of the USP foundation:

- medium fraction sand;

- crushed stone of medium size;

- geotextile;

- extruded polystyrene foam 100 mm thick;

- drainage pipes;

- wooden boards;

- reinforcement rods;

- knitting wire;

- pipes of different diameters for utilities and water floor heating;

- nylon clamps;

To work you will need the following tools:

- shovel and bayonet blades;

- wheelbarrow;

- level;

- building level;

- screwdriver;

- knife;

- Bulgarian;

- vibrating plate;

- deep vibrator;

- hacksaw;

- concrete mixer;

- trowel;

- protective clothing.

Excavation and drainage

A warm foundation cannot be laid on a vegetation layer, the thickness of which does not exceed 0.3-0.5 m, therefore it should be removed completely. To do this, you can use bayonet shovels. If the foundation is laid on a fertile layer, it will inevitably shrink, which will be the result of organic decomposition.

Before pouring the USHP foundation, you need to remove the fertile layer, fill it with sand and tamp it

Useful advice! For reliability, it is recommended to treat the area freed from vegetation with chemicals that stop further plant growth.

After sampling the soil, the surface must be tamped with clay, which in a dry crushed form is poured into the pit, moistened and rammed. Next, geotextiles are laid. The ends of the woven fabric should protrude beyond the future foundation by at least 30 cm.

In order for the slab to always remain dry, it is important to properly organize a drainage system, thanks to which ground, storm and melt water will be drained from the base of the foundation. For this purpose, along the entire perimeter of the excavation, it is necessary to make a trench with a depth equal to the diameter of the perforated pipes that will be used for drainage. Here, a slope of 3-4 degrees from the structure should be performed, which will ensure gravity. In the corners of the building, it is required to equip vertical wells, thanks to which access to the drainage system is provided for periodic cleaning.

In order for the slab to always remain dry, it is important to properly organize the drainage system of the foundation.

The sequence of actions is as follows:

- a layer of crushed stone is laid on the geotextile;

- at the corners of the structure, installation of wells is carried out, which are created from solid smooth or corrugated pipes with a diameter of 20-30 cm, installed vertically;

- installation of corrugated pipes along the perimeter of the building with the ends entering adjacent wells, where the corresponding holes are made;

- filling the trench with rubble, which is covered with geotextiles from above.

Layout of utilities and creation of an amortization cushion

Next, they start arranging a cushion with a thickness of about 15 cm from gravel or crushed stone with a size of fractions of 20-40 mm. The base is covered with fine sand, which is compacted every 20 cm with a manual rammer or vibrator until the design level is reached.

All utilities must be laid before creating a monolithic foundation, therefore they are placed on a sand cushion with a seal according to the wiring plan below the freezing level. All pipe ends must be brought to the surface for further connection of the system. To increase the maintainability of the networks, it is better to lay pipes in cases of a larger diameter. For the sewerage system, a well should be provided on the outside so that the sewerage system can be revised and repaired.

All existing pipes from under the foundation must be brought to the surface for further connection of systems

Useful advice! As a fallback in case of failure of the main communications, a dubbing of the engineering system is created, which can be switched to when repairing the old one.

After laying all utilities, the surface is covered with a small layer of gravel up to 15 cm thick, followed by compaction. For good waterproofing, the base is covered with a waterproof material. Here you can use both an inexpensive roofing material and more modern products. The canvases are overlapped by 10 cm with sealing of the joints. The edges of the waterproofing material must protrude at least 15 cm beyond the foundation.

Installation of a heat-insulating layer for the USP foundation

Insulation of the foundation is an important measure, due to which heat does not escape from the building into the ground, and cold does not penetrate from the soil into the room.The insulation must be of high strength. Therefore, in the USP technology, it is recommended to use plates made of extruded polystyrene foam, which (due to the presence of graphite in their composition) are characterized by increased compressive strength.

Useful advice! Ants and other insects can grow in polystyrene foam. Therefore, the material needs additional protection. Here it is recommended to use cullet, metal mesh or ceramic foam plates.

Material in the form of 10 cm thick slabs must be laid in two layers. The first one should cover the entire perimeter of the base and the blind area. The second layer should be laid with an offset of at least 45 cm from the edge, which will create stiffening ribs. In the middle of the slab, in the layer of thermal insulation, grooves 20-30 cm wide are made for future load-bearing walls, under which the insulation does not fit.

When using flat sheets of insulation material, special plastic nails with wide heads are used to fasten them. The points of contact can be treated with adhesive. It is recommended to arrange the elements in a checkerboard pattern, which will help to avoid the formation of cold bridges in the places where they are joined. You can also use l blocks for USB, which are mounted at the ends of the structure. Having a special design, they do not require additional fastening during installation.

Which insulation is better for the foundation

Today, a wide range of insulation materials from well-known manufacturers such as Technonikol, Styrex, Technoplex, Penoplex and URSA are presented on the construction market. PSB-S material is not suitable for these works, since it is produced without a pressing step.

Among all the proposed options, the extruded polystyrene foam Penoplex occupies a leading position. The cost of the product is 1200 rubles / pack. The material is characterized by a number of distinctive advantages:

- durability;

- multifunctionality, since it simultaneously creates hydro and thermal insulation;

- environmentally friendly safety;

- increased resistance to moisture;

- not prone to nucleation in the thickness of the layer of various microorganisms.

Also, the insulation for the USHP Technonikol is no less popular. The material does not absorb moisture, does not shrink, does not swell, is characterized by a low coefficient of thermal conductivity, exhibits chemical resistance and does not rot. For the manufacture of extruded polystyrene foam Technonikol, nanosized particles of carbohydrate are used, which increases the strength of the material, reducing its thermal conductivity, thereby increasing energy efficiency.

Insulation of the foundation - a very important task, therefore, when choosing a suitable material, it is necessary to take into account its characteristics

The material is characterized by high compressive strength and stable thickness under load, so that it can be used for loaded structures. You can buy material from 1400 rubles / unit, the cost of l blocks for USB is on average 1300 rubles / unit.

At this stage, a wooden formwork is laid under the future monolithic tiles. For this, racks are mounted, to which edged boards are attached using self-tapping screws and a screwdriver. The wooden frame is additionally reinforced with braces to give the structure more strength. The formwork is laid out from the inside with heat-insulating material. After the slab has gained sufficient strength, the fence is dismantled, and the insulation remains as protective sides of the lower part of the structure.

The value of a double layer of thermal insulation and underfloor heating systems for a home on USHP

Due to the fact that UWB technology requires two layers of thermal insulation material, all the heat will remain in the house.The first layer of 10 cm around the entire perimeter of the base prevents moisture penetration. The other 10 cm of thermal insulation creates a good barrier from the cold that comes from the ground.

Since the warm floor is poured into concrete, the monolithic slab serves as an excellent heat accumulator

Thanks to the underfloor heating system, which is installed in separate circuits in each room, an even distribution of heat in the room is ensured and the climatic zones are regulated. If you create the necessary insulation of the walls and roof of the building, it will be enough to maintain the temperature in the heating system no more than 28 degrees, which corresponds to the temperature of the circulating fluid (31-32 degrees), in order to create a comfortable microclimate in the house. However, this also depends on the finish of the flooring. Such measures will provide an additional advantage when using low temperature heat sources such as gas condensing boilers and heat pumps.

Thanks to the foundation in the form of a warm Swedish stove, you can save about 30% on heating. This is possible due to the fact that the underfloor heating system heats the concrete slab, and the concrete accumulates heat into the room. The thermal conductivity coefficient has a value of 0.17 W / m²K, and for non-insulated concrete bases it is equal to 0.4 W / m²K.

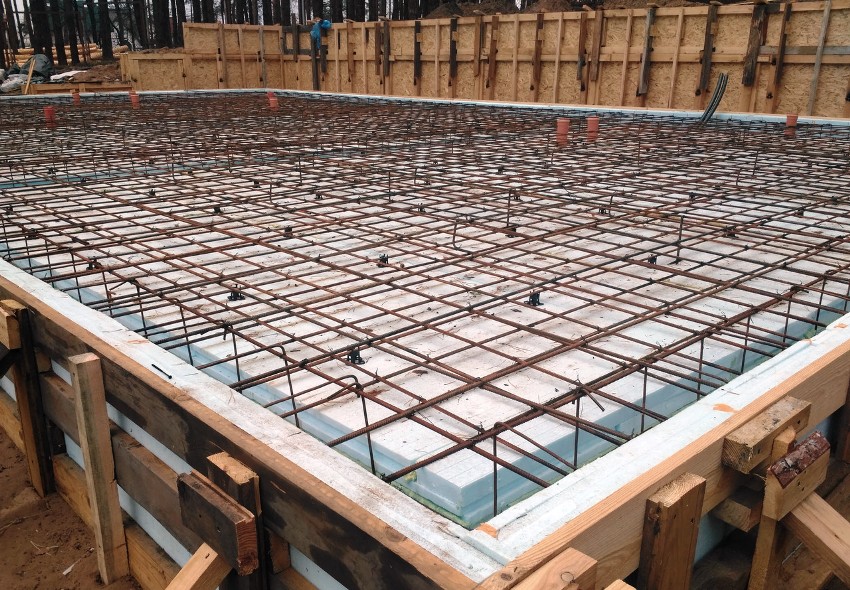

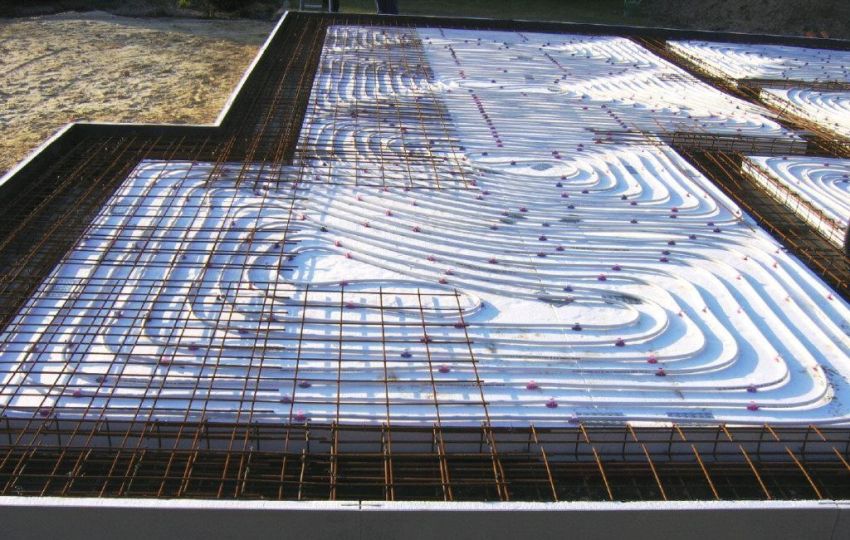

Reinforcement of the foundation of the Swedish slab and installation of a warm floor

Reinforcement of the foundation is performed for the structure to absorb tensile loads. The technology is performed according to the following scheme:

- creation of stiffeners for the grillage: from reinforcement with a thickness of 10-16 mm, connected by rectangular clamps of 6-8 mm with a step of 300 mm, frames are laid taking into account the protective layer of concrete;

- reinforcement of the slab: installation between the stiffeners of two reinforcing meshes with cells of 150x150 mm made of rods with a thickness of 10-14 mm, a cell width of 15 cm with strapping of structural elements with wire twists every 25-30 cm.

The thickness of the rods is selected taking into account the structural, snow and operational loads on the surface. Utilities should not be installed in the stiffeners. In order not to damage the insulation, it is recommended to assemble the spatial reinforcement cage separately, and then you need to lay it ready-made on special clamps in the area where the grillage is located, where the frames are interconnected. The binding of the slab mesh is done on site. The lower structure is mounted on PVC clips.

The technology of the Swedish insulated slab involves the installation of a warm floor in the thickness of a monolithic foundation. The underfloor heating contour is laid on the upper mesh and is attached with nylon clamps. In this regard, the thickness of the upper concrete cover should be taken into account, which should be 50-70 mm. In places where load-bearing walls or doorways are located, pipes should be placed in sleeves made of durable material. There must be a distance of at least 10 cm between the pipes.

If the styling is more dense, this will not affect the efficiency, but it will entail an overconsumption of material. Distances exceeding 25 cm will impair the even distribution of heat over the surface. The pipes must be placed more tightly near the walls than in the central part of future rooms. An indent of about 15 cm should be made from the wall.

Important! Heating pipes for a water-heated floor should be arranged with an insulated circuit for each room separately, which will allow heating each room independently of the others.

The distribution elements of the system are brought up and fixed on the rods driven vertically. The collector should be located in the place provided by the project at a given height. For its construction, four reinforcing bars 1.5 m long are driven into the foundation. A board is fixed on them and the collector is temporarily fixed. Underfloor heating pipes are connected to it.In places where flexible pipes rise to the collector, they must be protected by using a special corrugated pipe.

Important! The heating system must be tested for tightness by filling it with a coolant.

In the USHP foundation, the entire area is covered with a welded reinforcing mesh, and reinforcement bars are used in the stiffening ribs

USB foundation: technology foundation concreting

The final stage of the installation of the insulated foundation slab is the pouring of the base with concrete. It is important here to complete the process one-time. To do this, you can use a concrete mixer truck with an installed concrete pump. The solution is evenly spread over the surface using shovels and trowels. To obtain a homogeneous surface, the fill should not spread over a distance of more than 1.5 m in diameter.

Portion filling can be performed at intervals of 1 hour. If it is necessary to interrupt for a longer time, work seams should be arranged. After the resumption of work, they are moistened with water and treated with a cement milk primer. The mortar should be compacted with a vibrating plate or vibrator.

To ensure that the final surface is even, the base is sanded. This is an important undertaking as the concrete slab is the floor of the first floor. Otherwise, you will have to spend extra on the leveling screed.

Useful advice! It is recommended to build a USHP foundation at the end of summer, when the groundwater level decreases.

During the curing period, the concrete surface should be properly cared for. In hot weather, it is necessary to moisten the foundation and cover it from precipitation with plastic wrap. De-formwork can be carried out after 48 hours at a temperature of 30 degrees, and after 5-7 days - in cold weather at a temperature of 10-12 degrees.

Turnkey USB foundation: price works

The insulated Swedish plate is a modern method of foundation equipment, which is gaining popularity in private and cottage housing construction. Today, many construction companies offer to perform high-quality and fast turnkey USB installation, the price of which depends on the size of the base, the location of the site, the properties of the soil, the list of works and the customer's wishes. It is calculated individually for each specific case. Using the USB calculator, which is easy to find on specialized sites on the Internet, you can also independently calculate the approximate cost of work. Here you will need data such as the area and perimeter of the base, the height of the edge of the slab.

The main list of services includes the following activities:

- preparatory work before the start of construction: site marking, excavation;

- laying geotextiles;

- sand and gravel cushion device;

- installation of all communication systems;

- manufacturing and installation of formwork;

- installation of thermal insulation and underfloor heating systems;

- knitting of a reinforcing cage from rods using a knitting wire;

- pouring concrete with compaction with a deep vibrator;

- grinding the base.

Important! The cost of the USB foundation includes the delivery of the necessary materials to the construction site.

Price sq. m of the Swedish foundation slab starts from 5500 rubles. The larger the footprint, the lower the cost will be. For example, the price of an insulated Swedish plate with dimensions of 150-200 m² will be 7,500 rubles, and with dimensions of 50-70 m², 9,000 rubles.

Despite the fact that the cost of constructing a USB foundation exceeds the cost of a traditional monolithic foundation, such a device in the future will significantly save on heating.

On the USHP foundation, you just need to put a box at home, and everything else is already inside - heating, communications, insulation

There are companies that offer an expanded range of services for the construction of turnkey UWB. In addition to the standard list, you can order geological surveys. In this case, the cost of work with the material will be 7,500 rubles.

The use of the technology of the insulated Swedish plate will help to significantly reduce material consumption and reduce the time allotted for construction. Thanks to the built-in underfloor heating, it will be possible to save on space heating due to the high energy-saving characteristics of this type of base. In order to obtain a high-quality and durable foundation, it is recommended to order USB from specialized companies.