The foundation is the basis of any capital structure; the strength and integrity of the building erected on it depends on the quality of its arrangement. In cases where the natural properties of the soil do not allow the use of an ordinary type of support, a pile structure is used. Before starting any construction, it is important to know how to properly build a pile foundation with your own hands. Step-by-step instructions, videos and a general description of the process will help you with this.

Content

- 1 The main purpose and types of pile foundations

- 2 How to build a pile foundation with your own hands: step by step instructions, video

- 2.1 Basic rules for the construction of a pile-grillage foundation with your own hands: step by step instructions

- 2.2 An example of calculating a pile foundation with a grillage

- 2.3 Do-it-yourself basic rules for erecting a pile-strip foundation: step-by-step instructions

- 2.4 Pile-screw foundation calculator

- 2.5 Basic rules for building a screw foundation with your own hands: step by step instructions

- 2.6 How to make a pile-screw foundation with a grillage

The main purpose and types of pile foundations

The pile foundation is used in the construction of industrial and residential facilities; it can be used in the construction of multi-storey buildings even on soft soils. Such a foundation can significantly reduce the process of building basements or completely exclude these construction works from the cost estimate. The main reasons for the construction of a pile foundation are as follows:

- weak top soil layer. Such soils may contain humus, peat impurities, sand, and clay. The presence of a large amount of water in the soil makes it quicksand. Such natural conditions create the need to transfer the load of the structure to denser and deeper soils;

- increased soil density. By applying pile foundation you can reduce the amount of land work. Also, the cost of preparation will decrease: digging a pit, hiring a truck, removing excavated soil, backfilling, purchasing concrete, and more.

The pile foundation has several varieties: pile-grillage, pile-screw, pile-tape. Each type has advantages and disadvantages, we will consider them in more detail.

Pile-grillage foundation: pros and cons

The use of a pile-grillage base has both positive and negative sides. The advantages of such a foundation:

- allows for construction on almost any type of soil;

- increased stability;

- increased bearing capacity (allows you to hold roofs and walls with a fairly high specific weight);

- cost-effectiveness (you do not need to use a ready-made solution, you can make it yourself);

- the solidity of the base makes it possible to settle the entire structure in the event of soil shrinkage;

- does not require special preparation of the construction site (cost reduction by reducing labor-intensive work);

- ensuring natural ventilation of the entire lower plane of the structure (humidity decreases, condensation is eliminated);

- safety (the risk of flooding is reduced in case of floods);

- speed of construction;

- high construction speed.

Important! The construction of a foundation on piles requires accuracy in calculations and adherence to construction technology. When overloading the tonnage of a support, there is a high risk of destruction of the building in the future.

Disadvantages of the pile-grillage foundation:

- the impossibility of erecting a pile-grillage foundation on stony soils;

- laboriousness of installation of the base with horizontal displacement of the soil;

- a rather high price of a pile-grillage foundation, which is much higher than the cost of other options;

- the impossibility of building a basement or basement (this type of foundation is used exclusively for lightweight and medium-weight structures);

- accuracy of calculations (errors in calculation will lead to deformation of the supports and the formation of cracks in the house). It is not cheap to order a calculation of a pile-grillage foundation from specialists. Consequently, the total cost of work will increase significantly.

Pile-screw foundation: pros and cons

This technology has been known since the last century, so its pros and cons have long been studied. Benefits:

- low price of a pile-screw foundation, which is several times cheaper than a monolithic or slab foundation;

- high speed of construction (there is no need for leveling the ground or digging trenches);

- minimal disturbance of the soil structure;

- lack of vibration (the ability to build buildings next to architectural monuments, monuments, age-old trees);

- recommended for installation on swampy ground, the banks of water bodies (ideal choice for the construction of a pier);

- complete independence from weather conditions;

- multiple use of the structure;

- installation work is carried out at minimal cost (physical, technical).

Disadvantages of the pile-screw foundation:

- supports are highly susceptible to corrosion (iron alloys are used for manufacturing);

- fragility;

- fragility of the structure;

- the inability to use the space under the house (it is strictly forbidden to build a basement or basement).

Pile-strip foundation: pros and cons

A fairly common type of foundation, which also has its own specific characteristics. Advantages of strip pile foundations:

- can be erected on areas with difficult land relief;

- efficiency (the minimum amount of equipment and human resources involved in the construction of the structure);

- the ability to withstand weak shocks and ground movements;

- piles can be made independently using only available material;

- speed of construction.

Related article:

How much is the foundation for a standing house: calculation, cost and order of work. Types and varieties of foundations. How to fill the foundation for a house with your own hands, photos and videos of the process.

Disadvantages of the strip pile foundation:

- the need for detailed geodetic measurements;

- individual calculation of the length, thickness and depth of each pile;

- the impossibility of creating a basement;

- compulsory work on insulation of the underground;

- used exclusively for the construction of low-rise buildings (maximum three floors).

How to build a pile foundation with your own hands: step by step instructions, video

Currently, the cost of any construction work has increased significantly. Therefore, many owners solve the problem of building a foundation on their own and using all kinds of improvised means. Let's consider in detail the main points of the construction of three types of pile foundations.

Basic rules for the construction of a pile-grillage foundation with your own hands: step by step instructions

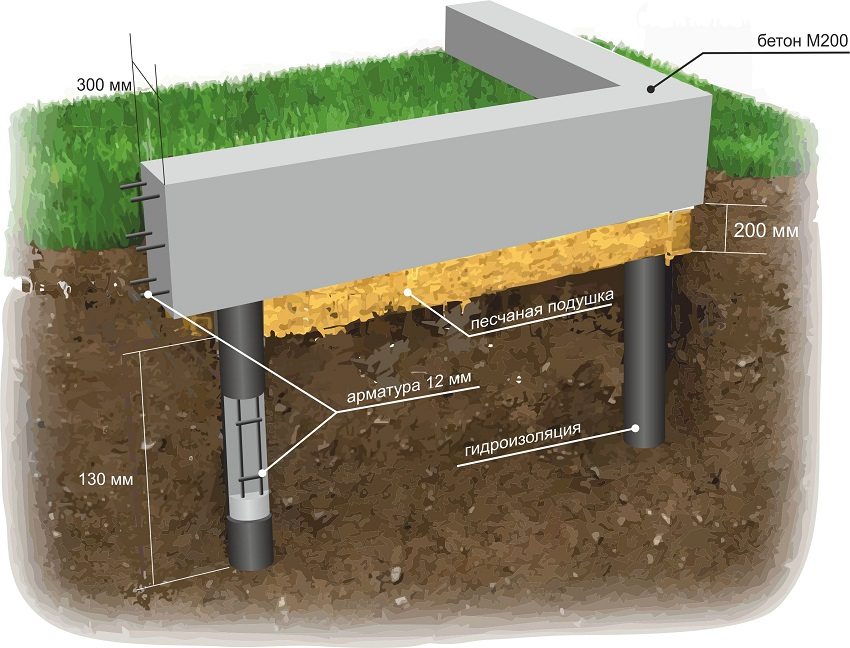

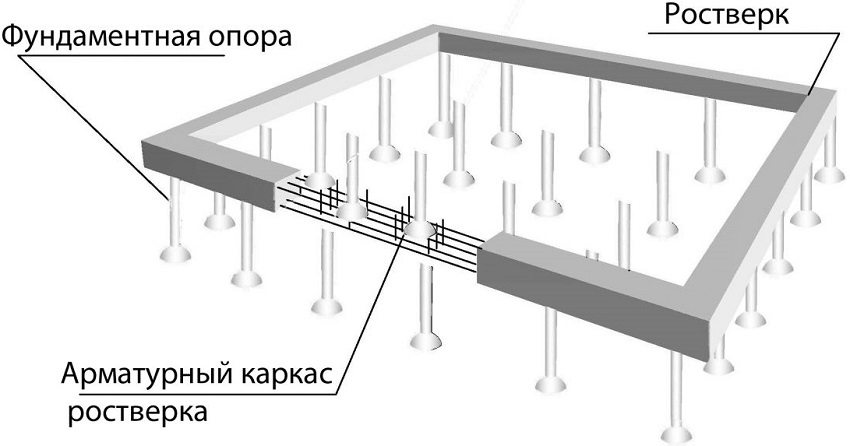

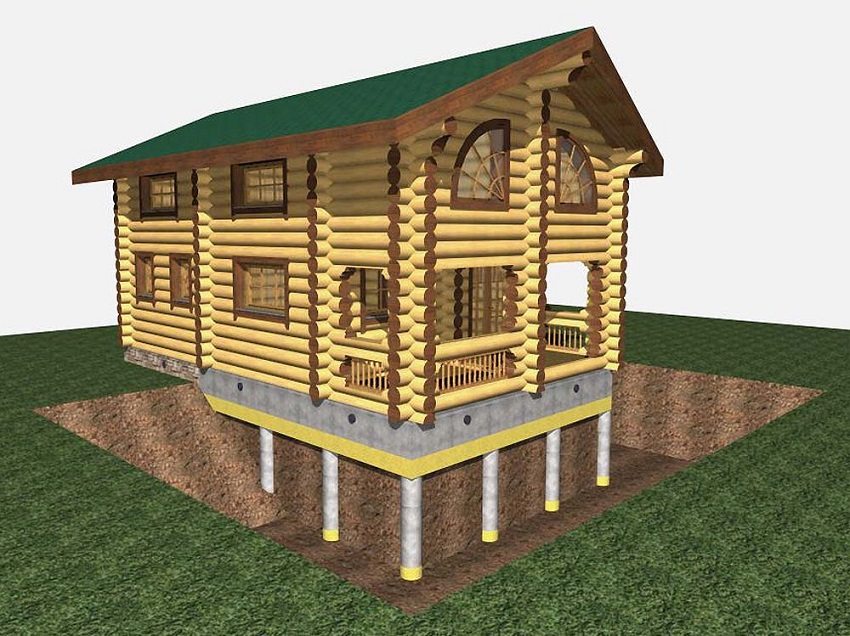

This type of foundation has a characteristic concrete base structure. A beam is fixed in it, which is poured out of concrete and reinforced with reinforced elements. This is a single system consisting of supports (piles) and a grillage.

The supporting function is performed by pillars of a round or rectangular shape. The posts are immersed to a specially calculated depth. It is on them that the entire weight component of the building is held. The grillage is a monolith that unites all installed piles.

The pile-grillage foundation can be erected independently, because there is no need to remove the soil. In order to drive the supports into the ground, special pressing devices are used. After the final installation of the piles, they are cut at the same level. Then a general connection is made with a grillage, which provides an even load on each individual support.

A photo of a pile-grillage foundation will show it much better than any detailed description. Often, the basis of the supports are metal pipes that are hollow from the inside. This makes them lighter than other types of piles. It is easier to drive them to a considerable depth. To increase stability, concrete is poured inside.

Important! The grillage in this case serves as a reliable and rigid basis for the next stage of construction - masonry walls.

The grillage can be done in two ways:

- Assemble from reinforced concrete elements.

- Pour in monolithic tape.

To build a foundation with your own hands, it is better to choose the second method - a monolithic grillage. This will make the task of pouring concrete much easier. Installation of weighty reinforced concrete blocks will require additional manpower and equipment. The sequence of action is as follows:

- provide a small space between the ground and the bottom of the grillage. This will help prevent the entire structure from swelling;

- mark the future location of the piles;

- drill wells and install piles;

- formwork should be laid on top;

- a reinforcement cage is mounted inside the formwork. It is necessary that it be completely submerged in the concrete solution. To do this, small bars should be placed under the lowest rods;

- the rods protruding from the support must be connected to the grillage reinforcement cage. This will provide the base with greater reliability and strength;

- after that, the grillage can be poured with concrete. Concreting is done in layers to avoid air pockets.

To choose the right one type of foundation, you need to proceed from the approximate weight of the future home. The pile-grillage foundation has sufficiently high load restrictions, therefore it is suitable as a base for buildings made of aerated concrete, panel boards and frame houses... It is not recommended to use this type of foundation for high-rise buildings due to the low resistance to overturning loads that occur on moving soils. The best option is the use of a pile-grillage foundation for aerated concrete.

Helpful advice! The width of the grillage should slightly exceed the width of the walls of the future structure. This will add sustainability to the building.

An example of calculating a pile foundation with a grillage

The total number of piles and their pitch are calculated for the construction of a one-story building with a size of 7x7 m.

The approximate weight of consumables (roof, timber, cladding, etc.) is 25,000 kg.

Payload: 7x7x150 (accepted value for residential premises) = 7350 kg.

Snow load: 7x7x180 (constant) = 8820 kg.

Calculation of the total mass of the load on the foundation: 25000 + 7350 + 8820 = 41170 kg.

This value must be multiplied by a safety factor of 1.1. We get 45287 kg.

Now it remains to divide the resulting value by the size of the load per one pile (for example, screw): 45287/2000 = 22.6435. After rounding, we get 23. This is the number of supports you need. Installation step - 1.2 m.

Do-it-yourself basic rules for erecting a pile-strip foundation: step-by-step instructions

If the site on which you decided to build a house has a complex relief, then it is more expedient for you to use a pile-strip foundation. It consists of a tape (grillage) and piles. The technology for the construction of this type of foundation is not particularly complicated, therefore it can be done with your own hands. To perform this work, observe the following rules:

- make the markup. To do this, drive in the rods at the corners of the future structure and pull a cord between them;

- determine the location of the piles;

- dig a pit for the tape;

- drill holes for piles on its bottom;

- install asbestos-cement pipes in the dug holes, filling them with about 30 cm of sand;

- equip a thorough waterproofing of piles with roofing material;

- install several metal rods in each pipe. The rods should rise 20 cm above the ground surface;

- fill each pipe with concrete, avoiding the appearance of air pockets;

- after the concrete has frozen, the tape is installed. For this, the bottom of the structure is laid out with bars 5 cm thick. Then a special mesh is installed. Mesh elements are securely connected to support reinforcement elements;

- formwork is installed (wooden shields, which are reinforced with struts and struts). The formwork should slightly exceed the height of the future plinth;

Helpful advice! To give additional reliability to the walls of the formwork, secure them with stakes driven into the ground (from the outside and inside). The tops of the stakes should be tied tightly with wire.

- concreting. It is necessary to pour concrete with periodic tamping, leaving no empty spaces.

Pile-screw foundation calculator

According to reviews, the pile-screw foundation is best used for the construction of residential and non-residential premises on moist soils.

Let's calculate the number of piles required using an example. Initial data:

- pile diameter - 40 cm;

- estimated weight of the house - 80 tons;

- the bearing capacity of the soil is 5 kg / cm2.

Calculation formula:

Fw = (πd2 / 4) × R.

Load per pile: 3.14 (constant value) x 1600 (diameter squared) = 5024.

We divide the resulting value by 4 (constant number) and multiply by the value of the soil bearing capacity: 5025/4 x 5 = 6280.

Required number of piles: 80t / 6280 = 12.738. Round off the resulting value.

You need 13 piles.

Remember that for the correct erection of the pile foundation, the calculation of the number of piles is a necessity. Erroneous calculations will lead to cracks in the house and the gradual destruction of its walls.

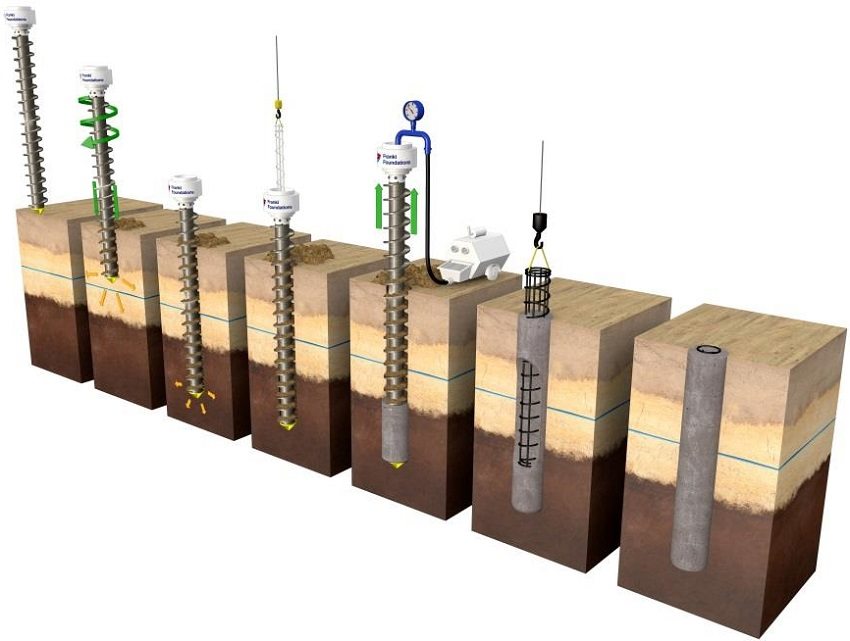

Basic rules for building a screw foundation with your own hands: step by step instructions

To build a house without a basement and basement, you should opt for a screw foundation. It consists of piles that are screwed into the ground like screws. Not recommended for hard soils. How to properly install screw piles for the foundation with your own hands - the video will show more clearly.Such video material can be easily found on the Internet. The construction process consists of the following stages:

- we determine the number of required supports and the amount of load on them. The calculation of the load of screw piles for the foundation is done according to the formula: area of the house x (40 + 15xB), where B is the height of the front of the building;

- we make markings on the land plot using stakes and a cord;

- we drill holes for piles. Their diameter should be slightly less than the diameter of the pile blades;

- we install supports;

Helpful advice! Be sure to use a level to maintain a strict vertical installation. If the support is not level, the foundation will not withstand the load.

- excess pile length is removed with a grinder;

- a steel platform is welded to the cut edge of the support. A metal channel is attached to it.

How to make a pile-screw foundation with a grillage

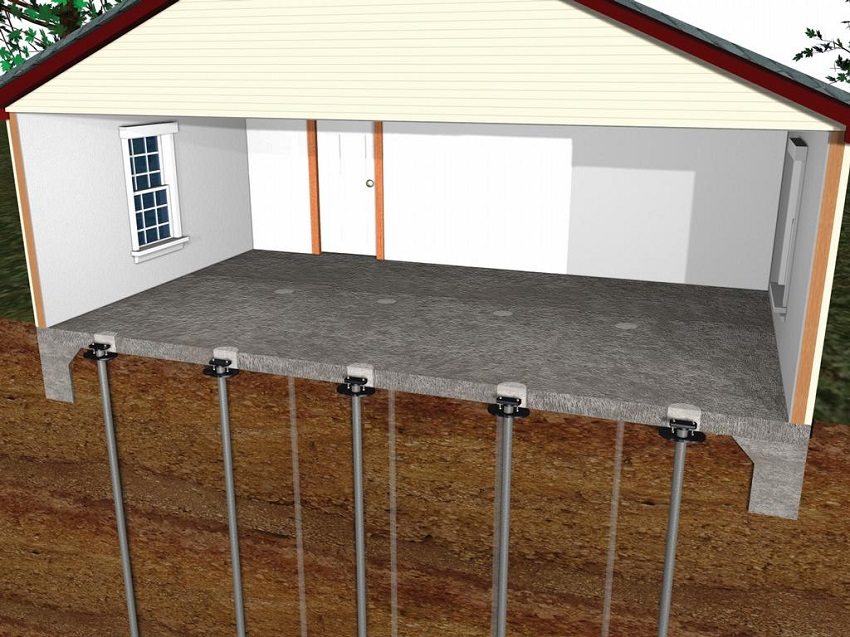

The grillage is that part of the foundation that rises above the ground surface. It is designed to distribute the load on the pile structure. For the manufacture of the grillage, reinforced concrete or metal beams are used, which combine the piles into a single structure. To properly build a grillage, the following sequence must be observed:

- formwork is being erected;

- fittings are laid. It is carefully strengthened to avoid possible displacement;

- concrete is poured. Make sure that there is no leakage outside the formwork;

- air is released from the concrete. This should be done using a conventional pin;

- the finished grillage is given time to harden. To do this, cover it with plastic wrap. During the week, it is necessary to periodically remove the polyethylene and water the structure;

- then the formwork is removed. The grillage is checked for size and shape.

To build a solid and reliable house, you need to properly equip its foundation. Before starting construction, carefully read the fundamentals of laying a building and the basic installation rules. Observing all the necessary technologies, you will perfectly cope with the independent construction of the foundation.