Any construction needs a reliable, high-quality, well-designed and equipped foundation. Today, the pile-based grillage foundation is very popular, which has economic benefits compared to the traditional strip foundation. The design feature is the horizontal lintel connecting the piles. Rostwerk: what it is and what is its main purpose is described in detail in the article.

Content

- 1 Rostwerk: what is this element and why is it needed

- 2 Varieties of grillage and what types it has

- 3 Characteristics of the pile foundation with grillage

- 4 Varieties of pile foundations with a grillage

- 5 Pile location options and their types

- 6 Pros and cons of the pile-grillage foundation

- 7 Calculation of the pile-grillage foundation

- 8 DIY pile-strip foundation

- 9 The device of a columnar foundation with a grillage

- 10 The main mistakes in the construction of a pile-grillage foundation

Rostwerk: what is this element and why is it needed

It is necessary to consider this issue with the definition: what is a foundation grillage. The internal building element is a horizontal concrete, steel or wooden lintel connecting the disparate elements of the columnar or pile foundation with each other, as a result of which a flat area is created for the installation of the flange. The grillage absorbs the load from the supporting structures of the building and distributes it evenly to the supports, which transfer the load to the ground.

Such a structure, in terms of its rigidity and strength, is not inferior to the traditional strip foundation, but the price of the grillage foundation will be much lower, which is associated with less labor costs and laboriousness of work.

The base structure is created using frame technology, where pillars or piles are tied together to form a solid base. The foundation with the grillage is built on clay, peat, loess, loamy, heaving and silty soils. The construction of a house can be carried out in areas with ornate relief or on slopes.

Varieties of grillage and what types it has

Ergonomics, durability and aesthetics of the building depend on the type of grillage, which is laid on a columnar or pile foundation.It can be slab, tape and glass.

Depending on the location of the grillage relative to the subgrade, the following types of structures are distinguished:

- increased;

- tall;

- recessed.

The jumper design can be:

- monolithic;

- prefabricated monolithic;

- national team.

Depending on the material of manufacture, grillages are distinguished:

- metal;

- wooden;

- concrete;

- reinforced concrete.

Element types and the main task of the grillage

The main purpose of the grillage is to take the load from the load-bearing elements of the building and distribute it evenly on the foundation. The most common and economically viable is the pile foundation.

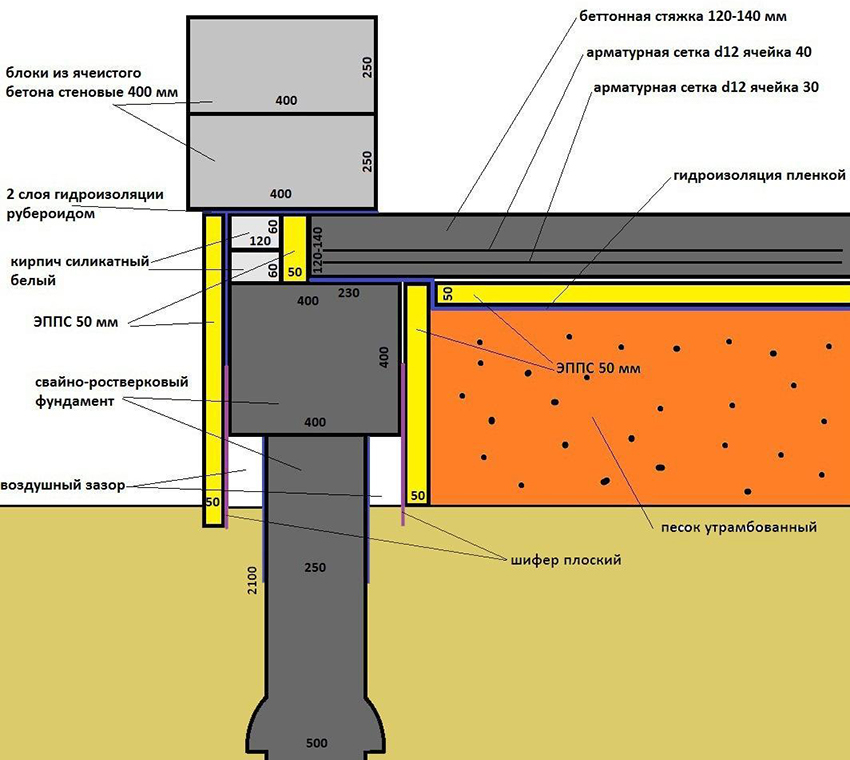

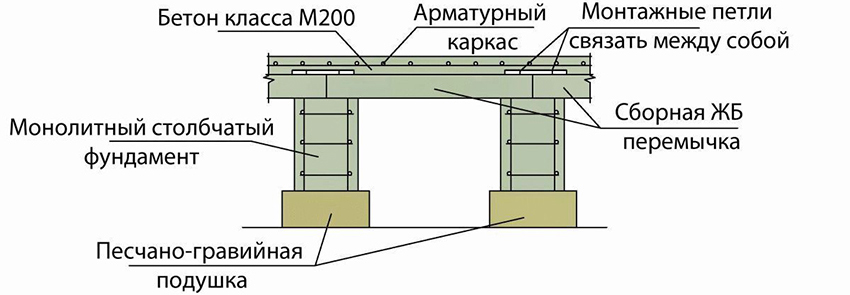

Slab grillage on piles in the form of large-format reinforced concrete slabs is installed with significant dimensions of the structure along its perimeter. Such a grillage fits on a standard cake consisting of:

- sand and gravel cushion in the form of two layers of 10 cm each with vibration compaction;

- ring drainage located at the level of the grillage sole;

- concrete preparation in the form of a screed without reinforcement;

- waterproofing.

If the groundwater is located quite high, then during the construction of such a structure there is no need to make additional bends

The strip foundation on piles can be monolithic or prefabricated. The first option is used for bored piles. This is due to the fact that the materials have the same linear expansion and technical characteristics. Also, in the body of the grillage, it is easier to brick up the heads with protruding reinforcement.

The prefabricated belt grillage is used in wood construction technology. Wooden beams are stacked on tops and joined in half a tree. This allows you to reduce construction costs and start building the structure the next day after the foundation is installed.

The prefabricated band grillage can be made in the form of reinforced concrete beams adjacent to the pile head. This design is mainly used for screw piles tied with I-beams or channels.

When installing reinforced concrete bored piles with a grillage, a glass type of structure can be used. The grillage is represented by a knee-cap mounted on a pillar, multiples of 15 cm high and 30 cm wide. Each glass must rest on four piles. This type of base is used when installing columns. Most often used in agricultural and industrial construction.

What is a grillage: element design

Monolithic grillage is the most successful solution for low-rise construction. The element is represented by a one-piece closed-type structure made of reinforced concrete or concrete. It is poured during construction, in the form of a monolithic slab or beam (tape). In the first version, the structure connects all the piles into a single system that covers the entire building area. The tape grillage connects the piles in series and is installed only under the supporting elements of the structure.

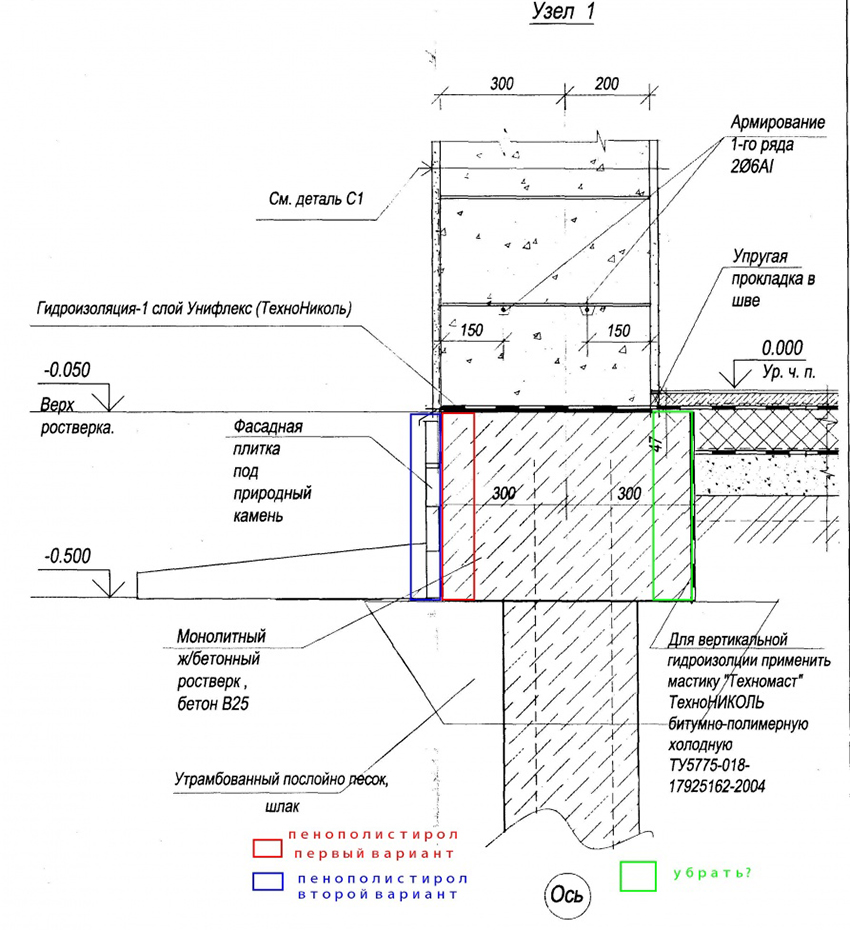

The grillage, securely fixing to the piles and including them in its thickness, connects the foundation elements. Monolithic tape grillage can be raised, high or deep. It is set up under unfavorable geological ground conditions. The implementation of such a grillage is distinguished by high technical and operational characteristics. However, the structure has increased labor intensity, high cost of work and requires the creation of a dense reinforcement.

The grillage performs the function of evenly distributing the load along the entire perimeter of the base

The prefabricated grillage is represented by a structure made of steel beams connected by welding. I-beams and beams are used as connecting elements.Also, the structure can be made of wooden beams. This option is used mainly for the construction of non-capital structures and industrial buildings. The structure is mounted and fixed on the pile heads, which does not require subsequent embedding.

Helpful advice! For the construction of a private house, a prefabricated grillage is impractical to use, because this is associated with a very laborious and costly process.

The prefabricated type also has its drawbacks. First of all, the installation process is very laborious due to the significant weight of the metal elements. In some places of the grillage, areas with low strength can form, which is associated with the low rigidity of welded joints. Due to the formation of corrosion or decay of wood, the structure is short-lived, which is limited to 1020 years of operation.

An intermediate solution between the two previous options is a monolithic prefabricated grillage. The prefabricated structure consists of prefabricated parts that are laid on piles and connected to each other with a keyway. This is done during construction. Then the whole structure is monolithic.

Optimal location of the grillage

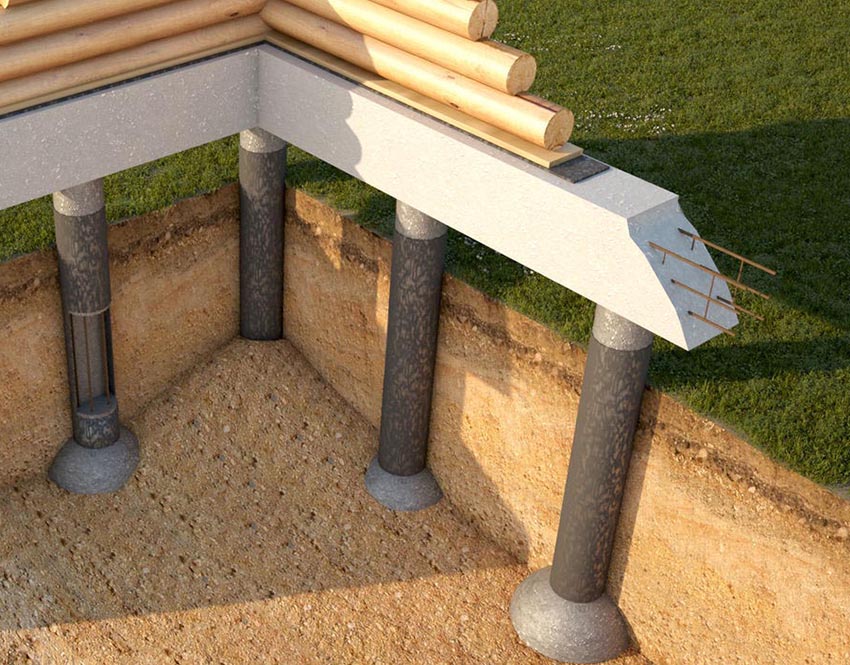

The most rational solution in terms of the integrity of the structure and the stability of its operation in the event of various deformations is the device of a high or hanging grillage on bored piles. It is installed above the ground level at least 10 cm. If the distance is less, there will be a possibility of damage to the integrity of the grillage and the nodes of its connection with the piles, which will lead to the pulling out of the latter.

The main disadvantage of this design is the lack of sealing the space between the bottom of the grillage and the ground. Due to the fact that free access of cold air is created, heat loss at home increases. The problem can be solved by installing panels or additional insulation of the floor of the house.

Helpful advice! It is advisable to choose this type of grillage for a subtropical climate, also when erecting wooden structures.

The sole of the raised grillage is located at the level of the ground, on which a gravel or sand cushion 10-15 cm thick is laid, for which a layer of soil is removed. This layer helps to reduce soil moisture under the building and free water filtration. This option excludes the formation of a blown area between the ground and the overlap.

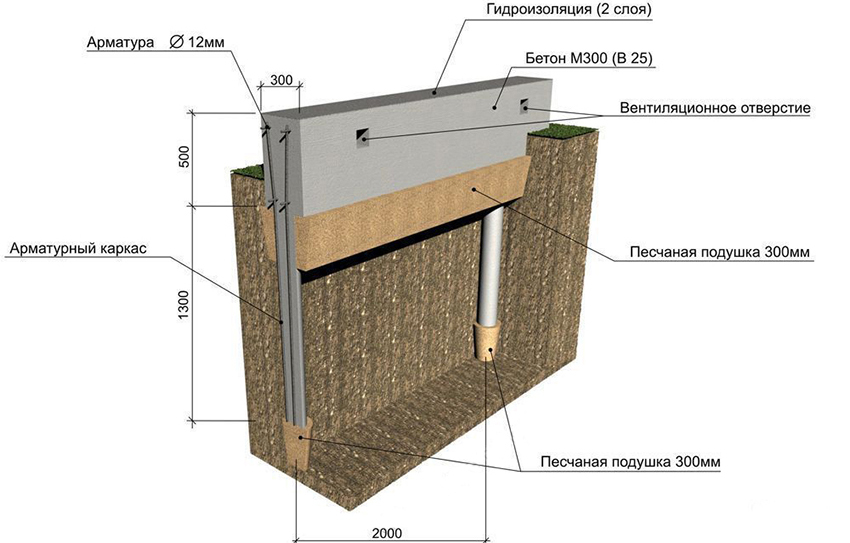

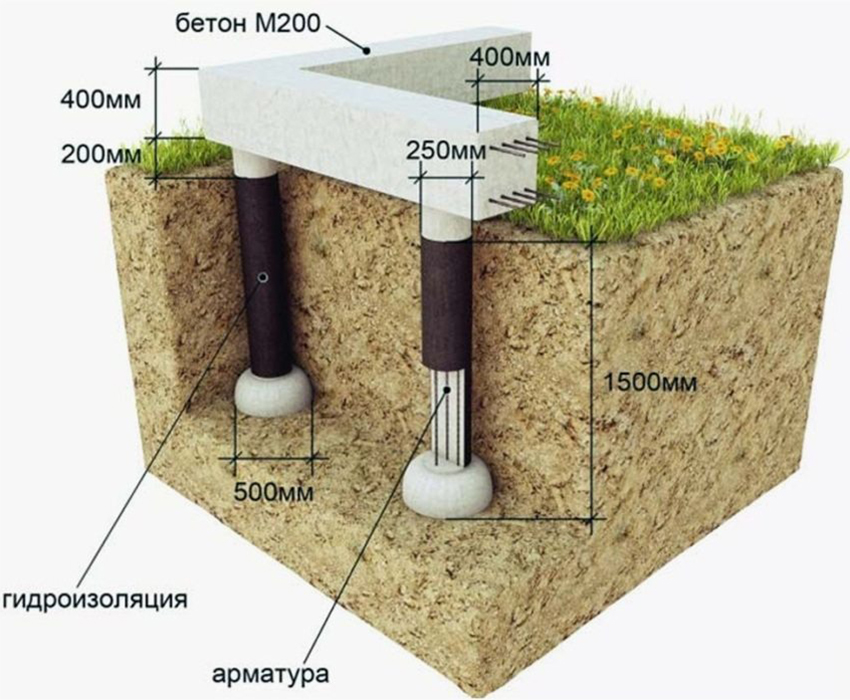

Recessed strip foundations on bored piles are the most popular option, and at the same time the most irrational. To create it, a shallow trench is cut out along the perimeter of the future building. Next, the piles are installed in such a way that their heads stick out from the bottom of the trench. A sand cushion is settling. After that, a gutter-formwork is performed, the bottom of which is located below ground level. Next, a concrete grillage is created.

Helpful advice! Despite the fact that a windproof space is formed under the buried grillage, centerboards can be mounted as additional insulation, which will perceive the load from the swollen soil during frosts.

What material is the grillage made of

Reinforced concrete grillage is characterized by increased strength, reliability, stability of operation, rigidity, bearing capacity and durability. This is the most common option. The structure includes reinforcement, which increases the strength characteristics of the grillage, taking on some of the loads. Reinforcement can be done by creating a full-fledged lattice girder or by laying individual bars.

Important! When forming a reinforced concrete grillage, a sufficient protective layer for the reinforcement must be provided.

The production of a concrete grillage is identical to the previous version. The difference is the lack of reinforcement. The entire load is taken up by the concrete structure, which covers the pile heads to a height of at least 10 cm. This option is less strong and durable. A concrete grillage is used in the construction of one-story buildings.

Manufacturing of a metal grillage is carried out from profiled rolled products, represented by I-beams and channels. The result is a sturdy and rigid construction. But due to possible corrosion of the metal, especially in the places of welded joints, the metal grillage is short-lived. It is used for the construction of one-story buildings.

The wooden grillage is used exclusively for the construction of wooden structures. Laying of a wooden beam is carried out through a waterproofing pad on piles, which is used as roofing material or roofing felt. Before installation, the beams should be treated with special compounds and antiseptics, which will exclude the formation of mold and the emergence of various parasites in the thickness of the wood. The timber is fastened to each other using bolts and brackets.

Characteristics of the pile foundation with grillage

A pile foundation is a structure in which the load on the soil from the structure is transmitted through the piles, which are represented by pillars or beams partially or completely buried in the ground. For a rigid and reliable connection of the upper parts of the piles, a grillage is arranged. It is rational to use this type of foundation when erecting buildings on water-saturated soft soils, on slopes with a steep slope, in areas where the depth of soil freezing exceeds 2 m, also if the weight of the future structure exceeds 350 tons.

Related article:

Drainage system around the house: drainage device for the foundation of a residential building

A drainage device to protect the foundation of the building, the specificity of this procedure, the technology for creating a structure with your own hands.

Piles are metal, wood or concrete, pointed, long or heeled rods of round or square cross-section. They are immersed in the ground in finished form or are made directly in the soil. In the finished form, the pile has a sharp end on one side, which, with the help of special construction equipment, is immersed in the soil, passing the moving layers, rests on solid soil. In the manufacture of piles in the ground, wells are drilled, which are subsequently reinforced and poured with concrete.

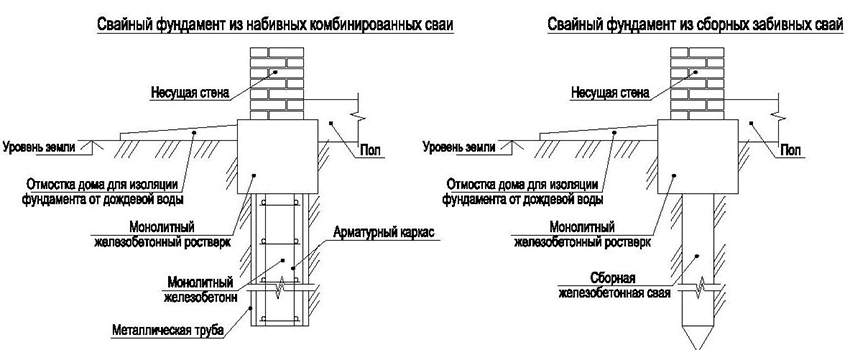

Varieties of pile foundations with a grillage

By the method of immersion in the ground, the pile foundation can be rammed, driven or screwed. The first option is represented by concrete or reinforced concrete structures. To create them, the reinforcement is pre-stressed, which increases the crack resistance of the foundation. To install piles in the earth, it is necessary to drill the required number of holes of a given diameter and depth. A metal or concrete casing pipe is inserted into each of them. The reinforcement is lowered into it and the entire cavity is poured with concrete.

The design can be made with a closed or open bottom end. The main advantage of this type of pile foundation is its high bearing capacity, simple technology, reduced cost of work, which is associated with minimal labor costs, and the absence of negative impact and vibration on the surrounding structures.

The second option involves driving finished reinforced concrete piles into the ground.As a special technique, pile drivers, vibrators and hydraulic piling units can be used, the choice of which depends on the characteristics of the soil, the characteristics and depth of pile driving. This type of foundation is used in permafrost zones. Driving elements can be round, square or trapezoidal. To increase reliability and bearing characteristics, piles can be equipped with additional support rings.

Screw grillage foundation: what is it

A foundation with a grillage on screw piles is one of the new options. The structure has good performance characteristics and can be installed on any type of soil. The pile is represented by a hollow tube, a sharp tip and one or more blades. The tip can be welded or cast.

For each type of soil, a certain type of screw piles is used. For stone areas, narrow-blade screw piles are used, which have especially strong welded tips and double blades, which provide reliable adhesion to the ground and prevent the pile from skewing. For thawed and watered soils, piles with a sharp cast tip and medium-sized blades are used, which is a guarantee of easy penetration of the element into the soil without loosening it.

For permafrost soils, piles with small blades are used, which contributes to the rapid introduction of the element into the soil without the risk of skewing. The head of the pile has a special cutter made of extra strong alloy steels. Such elements are of high cost.

Pile location options and their types

Piles can be hanging or in the form of racks. In the first variant, the load on the surrounding soil is transferred through friction against the side walls. Such piles are characterized by a developed lateral surface along the entire length with many protrusions, which provides a good bearing capacity of the structure. This type is used for soils with a high level of groundwater or with a thick layer of soft soil, under which a more durable one is located, but it is still not able to hold the pile-rack.

Rack piles transfer the load from the structure directly to the solid soil, which is located under the weak layer. The elements are characterized by a smooth surface that the soil does not cling to. The most important criterion for this type of pile is a wide base, which takes more than 80% of the total load.

Helpful advice! For multi-storey and durable buildings, it is advisable to choose TISE pile-posts, which have significant broadening in the lower part of the element, which makes it possible to exclude further settlement.

Piles in the ground can be located in one of the following ways:

- single;

- tape;

- stripes;

- in the form of a bush;

- field.

The first method is selected for a free-standing support. Depending on the features of the relief, the pile can be installed inclined. The belt method involves the placement of piles along the entire perimeter of the structure. For the construction of massive multi-storey structures, piles are installed in several rows in the form of strips.

Bush placement involves the installation of elements under load-bearing walls and objects with heavy loads. This method is used for the construction of sheds and structures with a large number of columns that hold the roof. For a large structure, staggered piling is used.

The choice of pile placement method depends on the construction project. Elements should be located in the corners and at the intersection of the walls. The optimal distance between the piles in the grillage is 2–3 m.

Pros and cons of the pile-grillage foundation

When choosing a foundation for a future structure, it is necessary to study the pros and cons of a pile foundation with a grillage. This structure has excellent stability and high load-bearing capacity. This is especially important for building houses on soils that tend to move. This type of foundation is often found in seismically active zones where the foundation will remain stationary during small earthquakes.

Important! Classic piles are capable of withstanding loads of up to several tons.

It is advisable to choose a pile-grillage foundation for the construction of structures on soils with a complex structure, especially in mountainous areas, which are characterized by a small layer of loose soil. Manufacturers produce piles of various lengths, which allows building foundations on slopes, as well as creating curved objects. The pile-grillage foundation is an ideal basis for the construction of a building from any material.

Due to the fact that the grillage does not come into contact with the ground, the likelihood of flooding of the structure with groundwater, rodents and various insects entering the house is excluded. For the construction of a pile foundation with a grillage, there is no need for preliminary cleaning and leveling of the construction site, which reduces the labor intensity and cost of work. The foundation can be erected independently without the involvement of powerful construction equipment, which is especially important in dense buildings or on small plots of land.

However, this design has its drawbacks. When designing this type of foundation, accurate calculations should be performed with the assistance of a specialist. Here you should take into account the length, diameter, weight, number of piles and their exact location.

Important! It is not recommended to use a pile foundation for heavy, massive structures, even by increasing the diameter of the pile elements.

Another disadvantage is the laborious repair of the foundation, which will require the construction of retaining walls or the installation of additional piles. The erection of a pile foundation with a grillage excludes the construction of a basement and requires additional insulation of the lower part of the building.

Calculation of the pile-grillage foundation

Calculation of the pile-grillage foundation is a serious and responsible undertaking. This process is best left to a specialist in the field. To perform the calculation, it is necessary to collect information about the area for construction: geological structure and physical properties of the soil, hydrogeological and physical-geographical conditions of the area. You can get all the necessary information from the local geological prospecting service after placing an order.

Based on the data obtained, calculations of the parameters of the selected foundation are performed. The load on the foundation with the grillage is calculated based on the total mass of the structure. Next, the depth of the support is calculated. Based on the bearing capacity of the foundation and the magnitude of the load, the minimum total area of the supports is determined. Next, the type, diameter and number of piles are selected, which are distributed over the area of the building, according to the selected layout. Further, the dimensions of the grillage are determined by calculation.

Helpful advice! To calculate the pile foundation with a grillage, you can use online calculators or the services of specialists from construction companies.

The calculation of the grillage of the pile foundation is carried out on the basis of SNiP II-B.1–62. It should be borne in mind that the width of the structure should be 10–20 cm thicker than the wall of the structure, and the height should be approximately equal to the width. The final stage is the selection of building material.

DIY pile-strip foundation

The construction of a grillage on a columnar or pile foundation with your own hands is a feasible and doable task. It is advisable to choose the first option for the construction of small structures without constant load, such as country houses and gazebos. The pile foundation is the most popular solution for the construction of buildings intended for permanent use.

It is advisable to carry out the device of the pile-grillage foundation with your own hands in late spring, early summer or early autumn. The first step is to prepare the site by clearing it of debris and vegetation.

Helpful advice! The area for future construction is recommended to be treated with chemicals, which will exclude the growth of vegetation.

Further, the territory is marked on the basis of the project, indicating the location of the piles. If screw piles are used, they must be screwed in without first creating holes. To do this, you can use a pipe or crowbar, which must be inserted into the head of the support. For screw piles, it is more convenient to make a metal or wooden grillage. It is advisable to arrange a concrete lintel only under the future stone house, which requires high rigidity of the base.

Important! Piles should be located strictly perpendicular to the ground.

If bored piles are arranged, it will not be possible to install them with your own hands. To create holes in the ground, you need to use a special technique. Bored piles can be made in two ways. The first option involves placing a formwork in the form of a metal pipe of the required diameter in each drilled hole. The internal space is reinforced and filled with concrete. The second option excludes the installation of formwork.

For the installation of a pile foundation with a grillage, concrete of class B7.5-B15 is used, which is the optimal solution for small buildings. For large buildings, concrete up to B25 can be used. A more durable building material is impractical to use for private housing construction. This is not economically justified, since the safety margin of the material exceeds the load from the building. Reinforcement with a diameter of 12-16 mm, class A400, is laid in each hole.

Laying a pile foundation with a monolithic grillage

For work, you will need the following tools and materials:

- bayonet and pick-up shovel;

- scrap;

- stakes;

- rope;

- wooden boards or chipboard sheets for formwork;

- set of steel screw piles;

- fittings for reinforcing piles and grillage;

- metal pipes;

- concrete solution;

- plumb line;

- level or hydro level;

- roulette;

- special chemicals;

- foam plates;

- sand;

- crushed stone;

- bituminous mastic.

The construction of a pile foundation with a monolithic grillage is performed according to the following algorithm:

- cleaning and leveling the base;

- drilling holes in designated places of the required depth and size for piles;

- compacting the soil and creating a cushion of sand of medium or coarse fraction 30-50 cm thick at the bottom of the holes;

- installation of screw or bored piles according to the production technology;

- preparation of a sand cushion for a monolithic grillage;

- formwork device;

- a reinforcement frame is lowered into the pit, consisting of at least 4 rods, the length of which is selected taking into account the height of the strapping;

- concrete pouring;

- creation of wooden formwork for a monolithic grillage;

- after the concrete has set, the reinforcement cage is collected for the grillage;

- installation of formwork for strapping;

- grillage concreting;

- removing the formwork after the concrete has gained the required strength;

- waterproofing.

Helpful advice! If an underground space is formed, it is better to close it with a decorative plinth or pick-up.

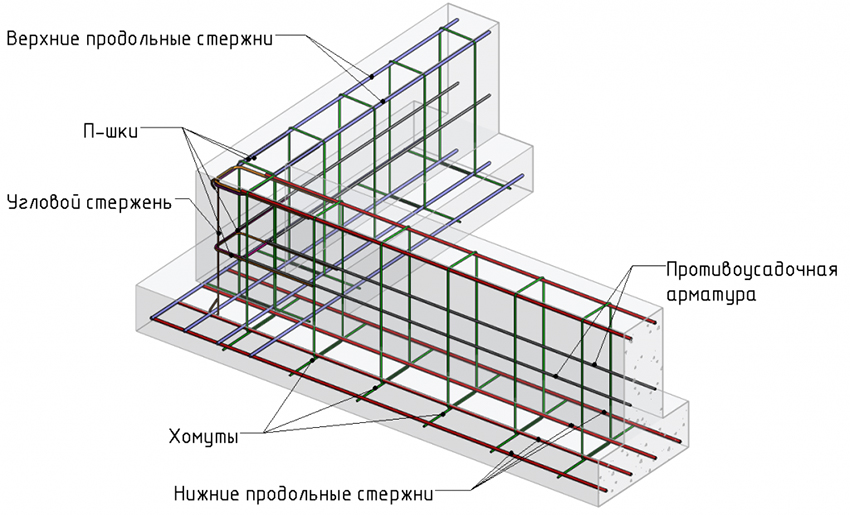

The grillage is reinforced with rods of class A400, which can be welded into a frame or tied with a knitting wire. The second option is more time consuming but reliable. When laying the frame, leave a distance of at least 3 cm from the rod to the formwork - to create a protective layer of concrete, which will prevent the formation of corrosion.

Helpful advice! At the corners of the building, reinforcement bars must be tied with wire.

Creation of a monolithic foundation grillage on piles

Before installing the grillage, a layer of waterproofing should be laid on the piles. This is necessary in order to prevent the soles of the elements from getting wet. Roofing material, polyethylene films or membranes can be used as a waterproofing material. If a cushion of fine gravel is provided under the base of the grillage, which may compromise the integrity of the waterproofing layer, a foundation should be provided.

The next step is the installation of formwork under the foundation on concrete piles. For this, marking is performed with a step of 0.5-0.8 m with driving in pegs with a cross section of 5x5 cm along the entire perimeter of the structure. Next, horizontal wooden planks are laid, in which pre-cut holes for piles.

Vertical formwork elements are installed, which are nailed to horizontal boards. For the formwork, it is recommended to use strong wooden boards or chipboard sheets. The inside of the prefabricated formwork should be covered with plastic wrap. The dimensions of the formwork must exceed the height of the future grillage by at least 5 cm.

Helpful advice! In the case of a low grillage device, you can use permanent formwork, which will later become additional thermal insulation for the walls of the premises.

Reinforcement of the grillage: step by step instructions

The next step in the construction of a pile foundation grillage is to create a reinforcing cage, which must subsequently be completely recessed into concrete from all sides. To do this, it is necessary to lay on the bottom of the formwork in the transverse direction wooden blocks of any width, but with the same thickness of 30-50 mm. The bottom row of reinforcement bars is laid on them, which must be tied together so as to ensure the same distance between the bars.

The upper belt of the reinforcing cage must be suspended from the transverse beams that tie the formwork props. Then you should tie the lower and upper belts together.

For the reinforcement of a monolithic strip, A400 class reinforcement is usually used. The number of rods is calculated based on the ratio of the cross-sectional area of the horizontal lintel to the sum of the cross-sections of all rods, which is 1000: 1. The following calculation procedure is performed:

- it is necessary to multiply the width by the height of the grillage, dividing the result by 1000;

- the resulting value must be divided by the cross-sectional area of one bar.

The result obtained is the minimum number of bars required for reinforcement.

Helpful advice! The distance between the rows of reinforcement should not exceed 150 mm.

Installation of additional elements and concreting of the grillage

Before pouring a horizontal lintel with concrete, special pipes should be laid through which engineering communications, such as water supply, heating, sewerage and communications, will pass. There should also be ventilation holes in the base.

Important! This stage should not be neglected, because then you will have to violate the integrity of the grillage.

To create a monolithic grillage, it is recommended to use concretes of the M300 and M500 brands. When filling the formwork with concrete, a vibrator should be used that is capable of shaking the concrete in order to eliminate the possibility of cavities, which will increase the strength characteristics of the concrete.

Two hours after pouring concrete, it is recommended to cover it with a film. If it is hot outside, periodically it is necessary to remove the film and wet the concrete with water so that cracks do not form on its surface. The complete solidification of the structure will occur no earlier than in a week, depending on the ambient temperature.

If the air temperature outside reaches 20 degrees, the formwork can be removed after 4 days, since the concrete base will gain more than half the strength. If the temperature does not rise above 10 degrees, the formwork does not need to be touched for 14 days. At air temperatures below 10 degrees. it is necessary to provide additional heating and organize the insulation of the foundation. After the concrete has completely hardened, you can start creating a waterproofing layer using bituminous mastic.

The device of a columnar foundation with a grillage

The foundation for a future building is carried out according to the following algorithm:

- clearing the territory from vegetation with subsequent treatment with chemicals;

- site marking based on the project;

- creating holes for future posts;

- compaction of soil at the bottom of the pit;

- creating a sand cushion with a height of at least 15 cm;

- laying geotextiles;

- backfilling with rubble;

- execution of formwork for each pit;

- covering the formwork system with polyethylene;

- creating a frame for reinforcing piles;

- the formation of pillars by pouring concrete into the holes;

- surface treatment of pillars with bituminous mastic;

- installation of formwork between reinforced concrete pillars to create a grillage, the height of which should exceed the height of the future structure by 5-10 cm;

- sand cushion device;

- concreting the grillage with structural reinforcement;

- creation of hydro and thermal insulation.

The prefabricated grillage is used for the construction of buildings where the service life does not exceed 20 years.

The main mistakes in the construction of a pile-grillage foundation

The first mistake that can significantly affect the reliability and rigidity of the structure is the incorrect calculation of the load on the base of the building. Here it is very important to take into account the peculiarity of the type of soil of the area where the construction will be carried out.

The next mistake is considered to be a shallow depth of laying or incorrect installation of piles. Free space can form in the soil under the piles, which will cause the base to shrink. This will undoubtedly lead to a decrease in the air gap under the grillage, which can cause the pile to break in the winter. To eliminate this possibility, the piles should be mounted below the depth of soil freezing.

In practice, there are cases when the project does not provide for the creation of an air gap under the grillage. This is especially dangerous during the winter period of the year, when the frozen ground expands significantly in different directions, including vertically. This will create excessive pressure on the bottom of the grillage, which can cause damage or breakage. To eliminate this, you should take care of organizing the insulation layer in the form of expanded polystyrene plates, which will also play the role of artificial depreciation.

An equally important point is the creation of a reliable connection between the grillage and the piles. If there is no reliable fixation, this can lead to horizontal displacement of the posts. As a result, they will not be affected by the design load from the structure, which can sink in this place.

A grillage foundation for a house or other structure is the most popular and economically viable option in modern construction. It is characterized by versatility, increased strength and reliability. A well-made grillage, in accordance with regulatory requirements, is the key to a durable structure.