Arrangement of the foundation is a serious undertaking, because this structure is the supporting structure for the whole house. The type of foundation is selected depending on the financial capabilities of the owner and the type of building (wood, concrete, etc.). The monolithic foundation slab includes iron reinforcement and concrete. Calculating it requires an understanding of the structure and knowledge of the formulas.

Content

- 1 Areas of application and features of a monolithic slab foundation

- 2 Advantages and disadvantages of monolithic foundation slabs

- 3 Monolithic foundation device: constituent elements

- 4 What are the varieties of monolithic concrete slabs

- 5 Calculation of a monolithic foundation slab: procedure

- 6 How to calculate a concrete slab with the foundation calculator

- 7 Slab Reinforcement: Process Implications

- 8 Preparation for the foundation of the base: step by step instructions

- 9 Foundation slab construction technology: concrete substrate

- 10 Pile-monolithic foundation: organization features

Areas of application and features of a monolithic slab foundation

This type of structure is classified as floating. Another feature of it is that it is located at a shallow depth in the ground. It is called monolithic because of its solid shape. A slab is laid under the entire area of the future residential building.

The monolithic foundation is a one-piece structure, thanks to which the house is provided with a stable base

Helpful information! The rules for placing this base take into account not only the depth, but also the presence of a special cushion, which includes two components: sand and gravel. It is needed in order to contain, cushion the pressure of the soil when it is swollen (heaving). The expansion of the soil occurs due to the freezing of the water contained in the soil.

Arrangement of such a foundation is often the only possible way out. If necessary, you can order a turnkey monolithic foundation. The price of such work depends on many individual factors. There are two known situations that have no alternative to setting a different basis:

- low stability soil;

- clay with a large freezing depth.

Such a foundation has a rather simple design, which, however, has many nuances, determined by the specific operating conditions of the foundation. Arrangement of a monolithic slab requires a large volume of concrete and metal reinforcement, as well as their correct ratio. The concrete must be of high quality - at least B30 grade. The concrete layer is reinforced over the entire area with a small margin. This increases the reliability of the plate.

Thus, the arrangement of such a base is quite expensive. The final price of a monolithic foundation slab is calculated depending on the area of the future structure and the density of reinforcement. In some cases, it can be lower than the cost of installing a tape structure, which is located at a greater depth.

Such a base can be used for installing columns. A monolithic foundation is very common in this case. To determine the depth of such a structure, it is required to calculate the weight of a residential building and determine the type of soil in a specific area. A slight deepening into the ground, prone to heaving, causes the building to rise in winter, but this is a completely acceptable situation.

Advantages and disadvantages of monolithic foundation slabs

A solid construction used as a base for a residential building has several advantages. In addition to the common advantages, you need to familiarize yourself with the disadvantages of such plates. The pros and cons of a monolithic foundation slab together make it possible to assess the feasibility of its organization.

First of all, it should be noted that the arrangement of a monolithic foundation does not require the use of special equipment. However, there may be exceptions. For example, when assembling a prefabricated variety, which is constructed from individual constituent elements.

The slabs of the strip foundation, as mentioned above, are laid deeper into the ground than a monolithic base. Therefore, using a slab as a base significantly reduces the amount of earthwork. For the installation of such a foundation, it will be enough to remove the top soil layer (fertile).

Helpful information! FROMthe flat design of the monolithic base contributes to an even distribution of the loads that the residential building has on it.

The tiled foundation has another very important advantage: it can be used in areas with unstable soil. The tape version is not suitable in this case.

Monolithic construction of the foundation allows you to evenly distribute the bearing load of the building

The next advantage is very important for those who want to make such a design on their own. It lies in the simplicity of its manufacture. All the skills that a worker must have to create it are in the ability to mix cement and design the formwork. Such a base is distinguished by high indicators of strength and reliability.

Monolithic foundation slab: main disadvantages

Almost any type of building can be erected on top of a monolithic structure. To create buildings, aerated concrete blocks, wood, brick, etc. are used. This structure has enough advantages, but it also has some disadvantages. For example, in order to install a monolithic slab, a flat surface is required. In building codes and regulations (SNiP), there are certain restrictions on this indicator.

After laying a monolithic reinforced concrete slab, the possibility of arranging a basement or cellar disappears.Also a serious disadvantage is the problematic laying of various communications, which arises from the continuous structure of the foundation.

A monolithic slab foundation can be laid for any type of building - a house, garage, bathhouse, etc.

To equip such a structure, you will need to purchase a large amount of materials. This will undoubtedly affect the final cost. That is why many people resort to installing a monolithic foundation with their own hands, without the involvement of special equipment.

Communication is worth mentioning separately. Plumbing and sewerage lines must be identified in advance in the foundation design. It is important to remember one more rule: pipes are laid before pouring, after which the main work is done.

Monolithic foundation device: constituent elements

The monolithic base is the most expensive. Based on this, every owner wants to save money on its installation. It is very important that the cost savings do not go too far, as this can affect the reliability of the foundation. It is necessary to enter into the project a slab of the minimum height at which the proper degree of strength will be ensured. There are several factors that are taken into account when calculating the width of a reinforced concrete foundation.

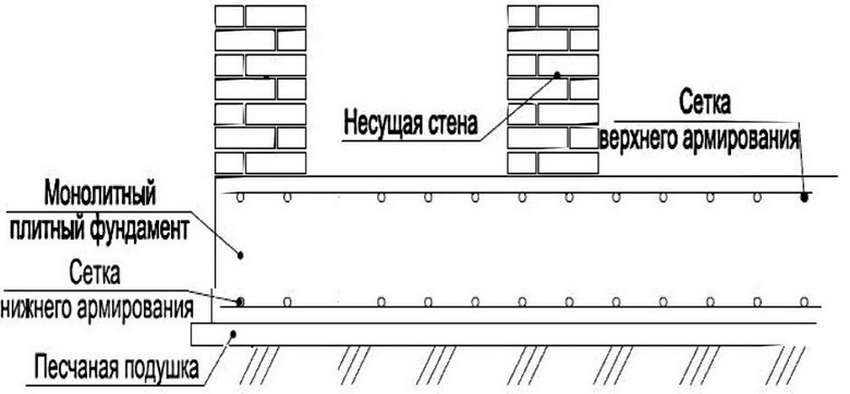

This type of structure consists of several layers, in addition to the main concrete part. First of all, it is necessary to determine the composition and characteristics of the soil on the site. A monolithic foundation slab for a house can be installed on almost any soil, however, the geometric parameters of the structure depend on its quality. A prerequisite is the removal of the top layer.

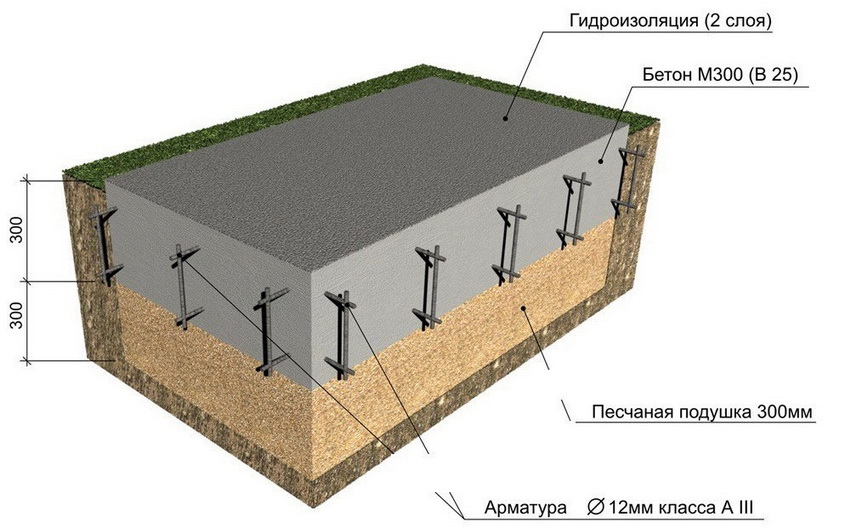

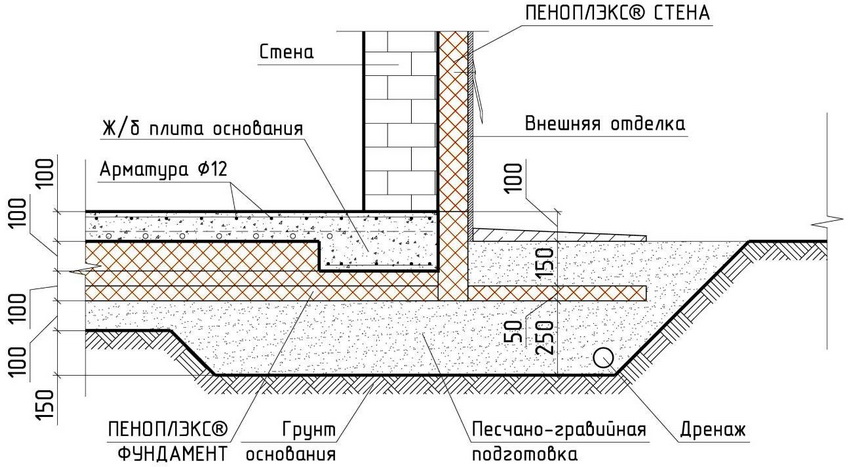

After the elimination of the fertile soil layer, it is necessary to fill in the bedding under the monolith into the pit. Sand mixed with crushed stone is used as a cushion for cushioning the foundation slab. The thickness of this layer varies from 40 to 60 cm, depending on how much clay the soil contains.

The next layer is a foundation, which is a small layer of concrete, which is necessary to level the base before pouring. And also the footing protects the carpet used as waterproofing.

After organizing the foundation, the waterproofing material is laid. For the tiled foundation, special rolls are used, which can be purchased at any hardware store.

Note! The installation of a monolithic foundation slab requires laying 2-3 layers of waterproofing material.

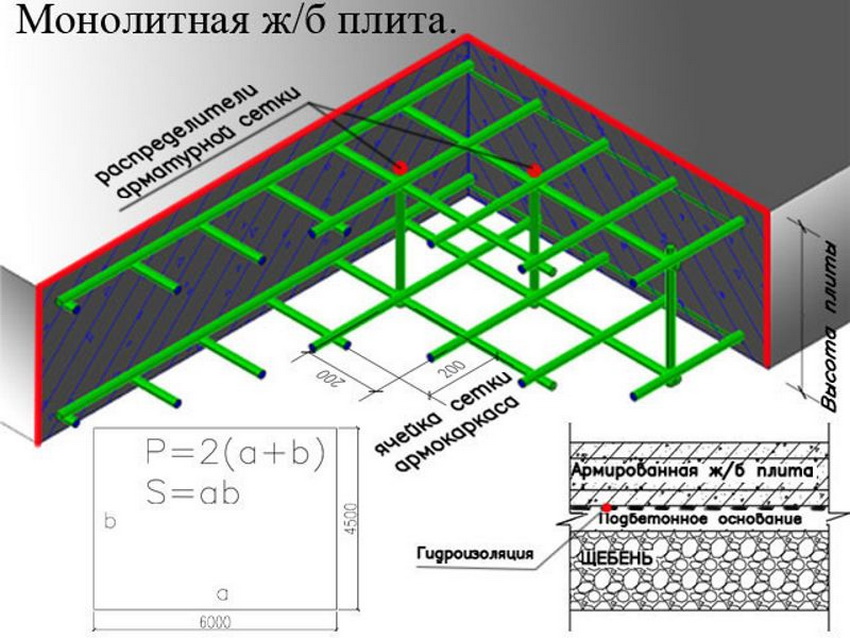

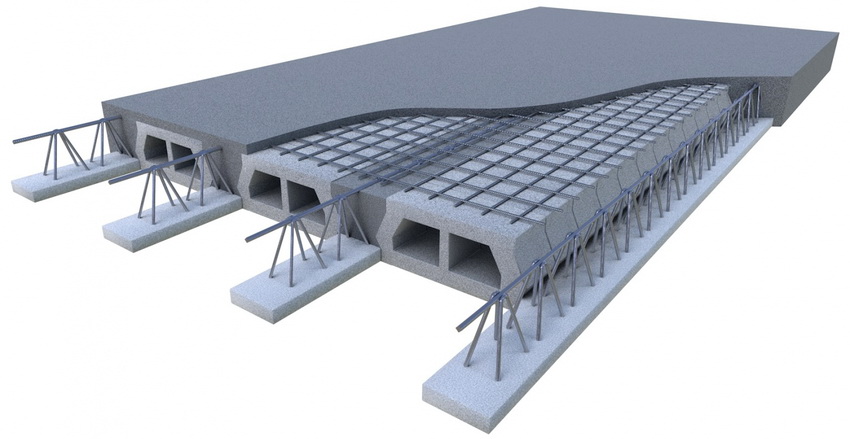

Next, thermal insulation is performed. It comes in two versions: rolls and slabs. Thermal insulation consists of expanded polystyrene (PPS), which has a high density. Then comes the main layer - concrete, inside which there are two reinforced gratings. They are intended to increase the integrity and strength of the structure. For example, a monolithic foundation for columns must be very strong.

It is important to remember that the top of the slab is necessarily located above the soil level. This can be explained quite simply: when laying wall materials, they, as a rule, sink to a certain depth into the ground.

What are the varieties of monolithic concrete slabs

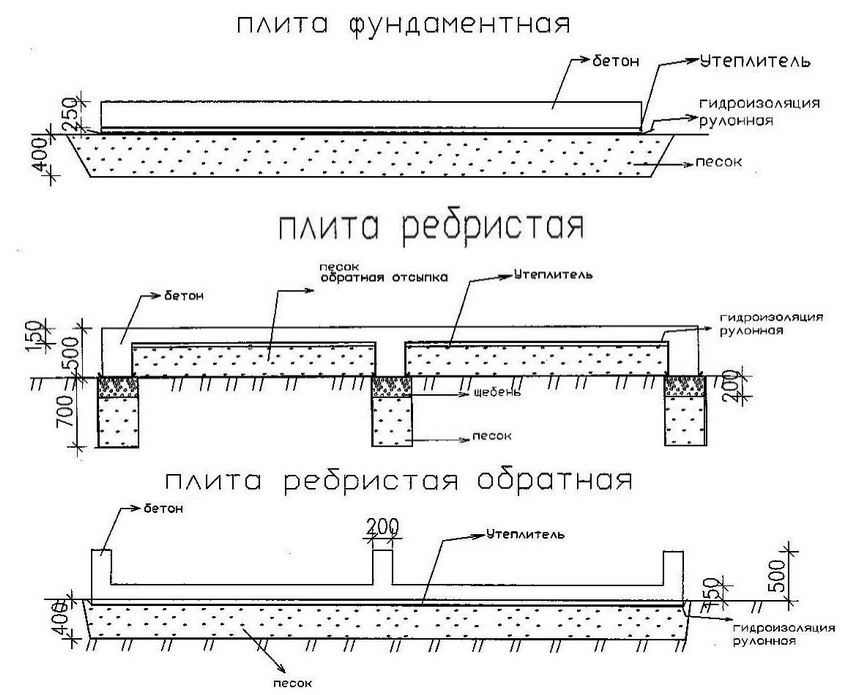

The main criterion by which monolithic concrete bases are classified is their internal structure. Depending on this, two types of such foundations can be distinguished:

- ordinary (monolithic);

- prefabricated monolithic.

In the first case, the laying technology includes the traditional sequence of actions, without any changes.Classical pouring of a slab with internal reinforcement is made on a sand and gravel lining.

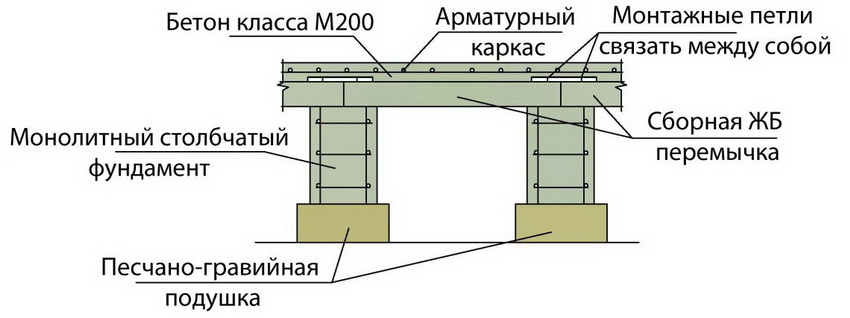

Installation of a precast monolithic foundation differs from the classic version. This method involves the use of finished reinforced concrete products. They are placed on a sand and gravel cushion. Then concrete mortar is poured over them (in a less wide layer), that is, in this case, the factory elements perform the function of the base.

Which type of monolith is better? Both the first and second options for organizing the foundation for a house are distinguished by their reliability and strength characteristics. Thus, according to these characteristics, they are equivalent.

The main advantage of the national team variety is a more affordable price. A slab of a turnkey monolithic foundation will cost 2-3 thousand rubles more. for 1 m². Prefabricated slabs have another small advantage: they accelerate the construction of the foundation, since they are produced in finished form.

What types of monolithic concrete foundation exist

Today, there are 3 main types of monolithic slabs. They all have their own structural and installation features. Before proceeding with the purchase of materials and subsequent installation, it is recommended that you familiarize yourself with each type of construction in more detail.

Related article:

USB foundation: construction manufacturing technology

Construction technology and slab design. Advantages and disadvantages of the foundation. Stages of mounting a compacted Swedish plate.

Classic stove. It consists of concrete and reinforced mesh, which is located inside the base. The technology for laying it is quite simple. The structure is placed on a cushion of sand and gravel. Insulation is not always a prerequisite for installation. The thickness of the monolithic reinforced concrete foundation depends on the soil and the mass of the building. The minimum indicator in this case is 20, and the maximum is 60 cm.

Note! The thickness of the cushion layer depends on how deep the top fertile soil layer is. It is removed completely, and the resulting pit is covered with sand and gravel composition.

Insulated Swedish plate (USHP). It is a technologically advanced monolithic structure that includes not only fittings, but also a warm floor system. Accordingly, the cost of this type of monolithic foundation is the highest.

There are other differences between the UWB and the classical design. The first of these is the fact that it is equipped with a special formwork, the shape of which corresponds to the Latin letter "L". This formwork is not removable, and its function is to prevent thermal energy leakage, which reduces the operating costs of the slab.

Another feature of the USHP is that the concrete layer located on top of the floor heating pipes and fittings has a thickness of 10 cm. In the production of such a structure, high-quality materials are used that have a long service life. This is due to the problematic nature of repair work in the event of a failure of one or another system passing or embedded in the slab.

Russian foundation. A distinctive feature of this reinforced concrete monolithic slab under the house is that it has stiffening ribs. Such structures are specially manufactured for the purpose of operation in non-standard, harsh conditions. The stiffeners are positioned so that they are under the load-bearing walls. They increase the resistance of the slab to frost heaving.

The downside of such a foundation is the complexity of its arrangement.This is due to the fact that it takes a separate time to install the stiffeners. However, the load-bearing capabilities of the solid structure are increased. The thickness of such a slab varies from 10 to 15 cm.

Calculation of a monolithic foundation slab: procedure

To correctly calculate the thickness of all foundation elements for a residential building, you need to follow a certain sequence of actions. Violation of this orderliness will spoil the structure and make it unusable. The first thing to calculate is the size of the sand and gravel cushion. It is important to consider that all dimensions are reflected in the final cost of the monolithic foundation slab.

Such a pillow performs several functions at once. The first is depreciation. And also worth noting the waterproofing function. The pillow is compressed under the influence of the gravity of the monolithic structure and creates reliable protection from groundwater. There are several features of determining the thickness of this layer, which is an important component of the slab foundation device.

This indicator varies from 15 to 60 cm, and there is a direct dependence of the thickness of the pillow on the depth of soil freezing. The amount of groundwater also plays a very important role.

The thickness of the monolithic foundation may depend on the characteristics of the soil and the expected load

Helpful information! Experts advise placing a small layer of fine gravel on top of the sand. Its thickness is determined individually, but it should not exceed 5-10 cm from the total height of the sand and gravel cushion.

If the site is located on the ground, the freezing depth of which exceeds 1 m, then it is recommended to lay the pillow in a thick layer (60 cm). The same goes for those areas that are located on unstable soils. The pillow is a very important element of the structure and protects the monolithic slab under the foundation from moisture. And, finally, the maximum size of the pillow should be chosen if the soil contains an excess of groundwater.

In areas with a depth of soil freezing up to 1 m, you can equip a pillow with a thickness of 20-30 cm. These dimensions require the presence of dense soil and the absence of groundwater. Thus, having determined the characteristics of the soil, it is not difficult to make the necessary calculation of the thickness of the pillow. Having determined this value, you can calculate how much materials will be required to organize it.

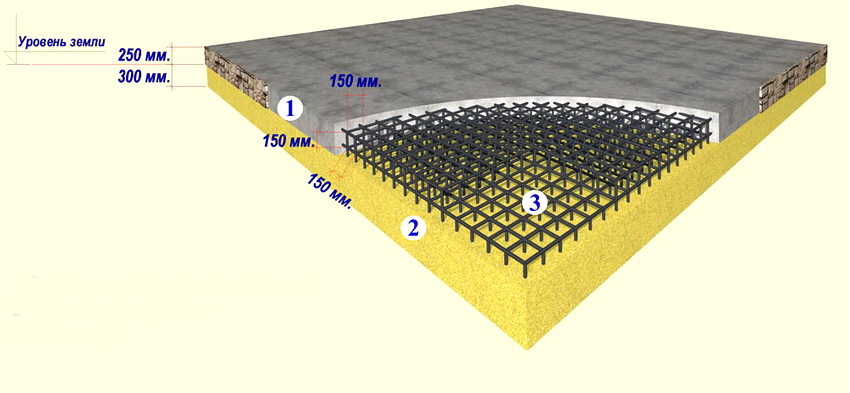

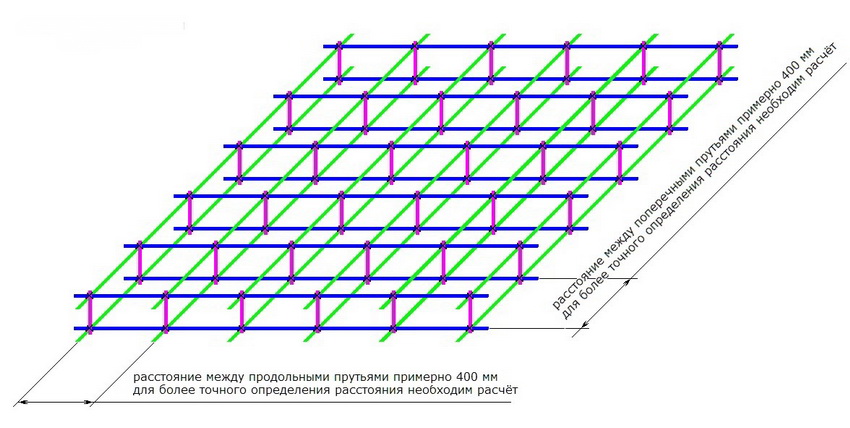

At the next stage of calculating a monolithic foundation, the number of necessary reinforcement is calculated, which will be required to stiffen the concrete slab. It is important to remember that the reinforcement mesh is laid in 2 layers. The distance between them should not exceed 5 cm.

After determining the amount of reinforcement, the slab itself is calculated. Its minimum thickness is 15 cm. The depth of soil freezing is the main characteristic that must be guided by when choosing this indicator. There is one important rule: the stock of concrete located at the edges of the reinforcing mesh should be at least 5 cm.

Calculation of the thickness of a monolithic foundation slab

For an optimal calculation of the thickness of a slab of this type, several indicators will need to be calculated. First of all, it is worth determining the distance between the first and second reinforcement meshes. Their location directly affects this geometric indicator. Next, you need to determine which layer of concrete should be above the reinforcement, as well as below it. In this case, it is worth taking into account the thickness of the rods from which the mesh will be made.

The standard thickness of the foundation slab is approximately 20-30 cm. However, with such dimensions, the structure negatively affects the composition of the soil, since its layers shift in the place where the monolith is installed.

The calculation also takes into account how much the slab will protrude above the top line of the soil on the site. In this case, the following pattern can be traced: the more the bearing walls are spaced, the thicker the monolith should be. A lot of material will be required for such a foundation. If necessary, you can make a strip monolithic foundation. A reinforced concrete structure of this type is solid, but it is installed in a horizontal plane in the ground.

It should be noted that there are certain regulatory documents according to which the foundation is calculated. When doing the foundation for a residential building on your own, you must definitely familiarize yourself with them before starting work. These documents take into account the calculation of the foundation thickness in two stages:

- collection of loads;

- calculation by bearing capacity.

Note! The reliability of the entire residential building depends on the thickness of the slab foundation. Any design errors can lead to the formation of cracks in the walls and their subsequent destruction.

At the first stage, the total mass of the building is calculated. The final figure should take into account not only the materials from which the house will be made, but also the weight of snow on the roof (in winter), interior items inside the house, as well as all residents. There are special tables by which you can determine the value of the load for a particular material. For example, for brick walls 510 mm this figure is 920 kg / m².

When performing calculations for other types of monolithic foundations (for example, a columnar monolithic foundation), additional measurements are required. In this case, everything depends on the structural elements.

To calculate the mass, you need to take a numerical value from the table corresponding to the material of your walls. This indicator already takes into account their thickness, therefore, to determine the weight of the building, you just need to multiply this value by the area.

Calculation of the reliability factor allows you to determine the service life of the foundation, and therefore the building as a whole

Determination and use of the safety factor

The safety factor is needed in order to determine the bearing capacity of the concrete structure. As a rule, this indicator can be easily taken in tables, which indicate the parameters of the loads for a particular material. When organizing a monolithic slab with your own hands, it is recommended to collect as much data as possible and perform the appropriate calculations.

The safety factor determines the bearing capacity margin. To do this, it should be multiplied by the load indicator. This parameter is very important, since when changing the purpose of the building, it is necessary in order to determine the feasibility of this decision.

This value varies from 1.05 to 1.4, depending on materials and load indicators. It should be noted that for a reinforced concrete monolithic structure, the coefficient will be 1.3. It is an invariable indicator that fully corresponds to the properties of this material.

To determine the amount of materials required for the construction of a monolithic foundation, special formulas are used

Determining the thickness of a monolithic foundation using the formula

In order to determine the total mass of a residential building, it is necessary to make a fairly simple calculation. You will need to first multiply the total area of the structure by the load indicator, and then by the safety factor. Then the resulting numbers are added. Thus, the total weight is determined.

After preparatory calculations, you can begin to calculate the most important thing - the thickness of the future foundation.To do this, you can use the monolithic foundation calculator or calculate using formulas. In the second case, you need to be careful, since it is very easy to make a mistake in this or that value or to write a number incorrectly. The first step is to determine the specific load. Consider the formula:

P1 = M1 / S, where:

P1 - specific load applied to the soil is presented in the table (excluding the foundation);

M1 is the total load (mass) from the building, which is determined when collecting loads;

S - area of reinforced concrete slab.

Note! To continue the calculations, you will need to find the difference between the specific load and the tabular value of this value. This is done quite simply: the second is subtracted from the first number.

Next, you need to determine the mass of the foundation, which is optimal for this situation. To do this, you need to multiply the difference in loads obtained above by the area of the concrete slab. And, finally, having all the necessary values at hand, you can easily calculate the thickness of the future monolithic foundation under the house. The calculation is performed according to the following formula:

T = (M2 / 2500) / S, where:

T is the thickness of the foundation;

M2 is the required weight of the building;

2500 - density of 1 cubic meter of reinforced concrete slab;

S is the area of the slab, calculated in m³.

Thus, the thickness of the concrete slab is calculated. The resulting figure is rarely round, so it is recommended to round it to the nearest value (0 or 5). In case of difficulties in determining these parameters, it is recommended to contact the professionals and think about the advisability of ordering a turnkey monolithic foundation.

When determining the thickness of the base plate of a residential building, it is advisable to independently use several methods simultaneously. There are other formulas, as well as online calculators, with which you can also get the required value.

How to calculate a concrete slab with the foundation calculator

An online calculator is a special program that is used to calculate all the required dimensions of the future structure. With the help of it, the thickness of the monolithic slab is calculated, as well as the size of its formwork and the amount of reinforcement. The reinforcement section indicator can also be determined using this program. This method has some advantages over formula calculations:

- data accuracy;

- saving time;

- availability of the function of 2D and 3D visualization.

The latter advantage is considered one of the most useful, as it allows you to assess the feasibility of a particular design in real time. Having a preliminary slab foundation model makes it much easier to find errors that were made during data entry.

Note! Thus, using a 3D model, if necessary, you can immediately correct the shortcomings and check the resulting version again.

Using the online calculator, it is quite easy to calculate the number of reinforcement and its diameter. If necessary, you can determine the permissible distance between the individual elements, as well as their mass. The online calculator of a monolithic foundation (slab) is able to make comparisons between the obtained data and the optimal values specified in SNiP.

These programs have other additional features. For example, you can define the thickness of the planks that will be used to build a timber formwork. It is also worth noting that the online calculator allows you to calculate the amount of insulation and the optimal proportions of concrete.

Slab Reinforcement: Process Implications

The concrete material copes well with compressive loads.However, it also has a weak point - low resistance to bending. For this, it is recommended to use special metal meshes made of reinforcement in the construction of monolithic slabs. They can significantly increase the strength and endurance of the slab to adverse influences of any kind.

Reinforcement of a monolithic foundation is a prerequisite that allows you to increase the resistance of the structure to external influences

Reinforcement of the slab foundation contributes to its resistance to external loads. Such impacts occur during the cold season, when the soil freezes to a certain depth. Thanks to the strengthening, the base of the building is able to withstand the short-term influence of moisture (for example, during a leak). Without metal mesh, when wet, concrete significantly loses its strength.

Reinforcement is a necessary step in the design of the foundation slab. Monolithic technology is based on the use of metal meshes. In order to perform the reinforcement of the foundation correctly, it is necessary to calculate the number of elements. It is also very important to accurately determine the geometric characteristics of the individual components from which the metal mesh will be constructed.

Note! If your house belongs to the category of standard ones, then you don't have to draw up a project yourself, but simply download a ready-made construction scheme on the Internet. However, experts recommend that you still check it before using it, as it sometimes contains errors. The implementation of such a scheme can be entrusted to a qualified organization, but it will cost quite a lot of money.

How to choose the right fittings for a slab foundation?

Monolithic bases are very popular in the construction of country houses and cottages. These residential buildings have one thing in common: they do not require a basement or cellar. For private houses, a monolithic reinforced concrete base is used less often.

To form a slab foundation with your own hands, you need to understand its design. It is a concrete slab, inside which iron bars are laid (in perpendicular directions). It is important to remember that there can be only one reinforcing mesh if the thickness of the cement base is less than 20 cm.

Before proceeding with the calculation of the number and dimensions of reinforcing elements, it is necessary to select a suitable brand of rods. It is determined depending on the operating conditions of the foundation. For example, if the soil on the site is dense enough, then you can purchase reinforcing bars that belong to the AI class. They are ribbed and are used in low lateral shear conditions. The diameter of such rods must be at least 10 mm.

In the case of building a slab foundation on unstable ground, a reinforced rod with an increased diameter is used. The cross-section must be at least 14 mm. It should be noted that the use of such elements is also recommended if the house is being built on a slope.

When selecting rods, it is also necessary to take into account what material the walls are made of. A monolithic foundation may not withstand the pressure exerted by the frame of the house if the reinforcement was selected incorrectly.

For light buildings (wooden or frame), it is recommended to use metal rods with a diameter of 10 to 12 mm. For more massive buildings made of brick or aerated concrete, you will need to purchase reinforcement with a size of 14-16 mm.

Helpful information! On the drawing of a monolithic foundation, a metal network is mandatory. The standard distance between individual metal elements in this design is 20 cm.This indicator is equally suitable for both longitudinal and transverse rods. Thus, you can quickly calculate that 5 elements are required for 1 m of the length of a residential building.

Preparation for the foundation of the base: step by step instructions

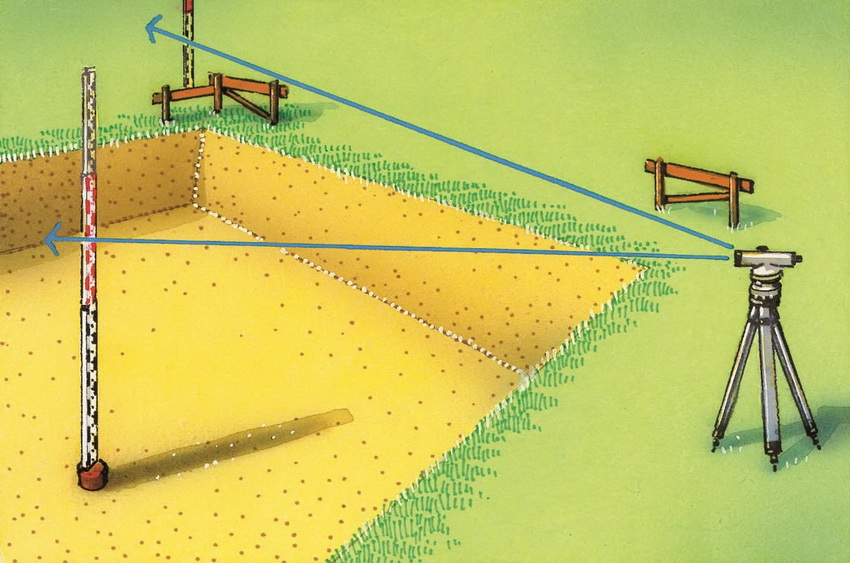

The dimensions of the pit, dug for a monolithic base, must be larger than the dimensions of a residential building. It is recommended to increase its length by 1 m. To organize the pit, it is necessary to carry out preliminary marking in accordance with the required dimensions (taking into account the stock). Further, the fertile soil layer is completely removed from this territory. The top layer of soil can have different thicknesses depending on the region (20-50 cm).

Then preparation for the construction of the foundation slab is carried out in accordance with the instructions. Drainage pipes are laid in the finished pit. They must be placed along the edge in the grooves prepared in advance so that they are located below the level of the bottom. This will ensure the removal of atmospheric water into drainage wells and protect the foundation from their harmful effects.

The precast-monolithic foundation also requires the organization of diverting communications. The bottom of the pit should be leveled and the soil compacted as much as possible. Then the geotextile is laid. It is important to remember that this material should cover not only the bottom, but also the walls of the pit.

Individual canvases overlap each other, after which their edges are glued together with reinforced tape. Geotextile performs a very important function - it prevents plant roots from growing into concrete. In addition, it prevents the sand from being washed out, which is a damper substrate.

At the next stage, sand is backfilled into the pit, covered with a geotextile cloth. It is desirable that it be of medium grain size. The thickness of this layer depends on the characteristics of the soil and ranges from 20 to 30 cm. This value of such a base determines the final cost of the work. The price of a monolithic foundation depends on the amount of materials used for its arrangement.

You cannot immediately pour all the sand into the pit. This process is carried out in stages, layer by layer. Each previous layer is compacted, and only after that the next one is performed. The recommended thickness of one layer is 8-10 cm.

At the next stage, gravel is backfilled. All gravel is distributed at once, after which it is necessary to level it as much as possible and, like sand, tamp it. Then work is organized on the laying of a water supply system and a sewer line. To do this, it is necessary to make trenches in the rubble, into which pipes will be laid. After laying the pipes, the ditches are filled with sand, which is then carefully compacted.

Foundation slab construction technology: concrete substrate

At the preparatory stage of building the foundation, one more action is performed. For maximum reliability of the future substrate for a monolithic slab, a concrete layer is used. Its application allows not only to ensure the strength of the bottom of the pit, but also to level it.

The process of forming a concrete base (or monolithic foundation slab) is quite simple. Formwork is performed first. It must be thick enough to resist the pressure of the concrete. As a rule, it is constructed from a board, the thickness of which is 40 mm.

Helpful information! If plywood was taken as the material for the formwork, then 18 mm can be limited.

The construction of a monolithic foundation is a rather complicated process. Care must be taken when assembling the formwork for the concrete substrate.The height of this structure is calculated very simply: it is necessary to measure the conditional height of the remaining layers following it.

The construction of a monolithic foundation slab is a complex process that requires a responsible approach.

The edge of the formwork must necessarily be flat, as this will allow you to control the height of the concrete pouring. Thus, it is not recommended to use an unedged board in this case: it will not be possible to make an even monolithic foundation. Formwork design work includes the installation of spacers to provide the required rigidity of the timber structure.

After the installation of the formwork, you can start pouring the concrete substrate. The thickness of the layer of such a litter is 10 cm. For its formation, it is allowed to use concrete of lower quality grades (from B7.5 to B10). The concrete base is a reliable and durable base. After laying it, you can proceed to waterproofing the foundation, as well as its insulation.

How to waterproof a foundation slab

The location of the monolithic base makes it vulnerable to moisture. In order to protect the foundation from the effects of precipitation, you will need to take care of its reliable waterproofing. Today, there are two common types of waterproofing:

- coating;

- roll.

For waterproofing a slab foundation, it is customary to use both of these types. Their combination significantly increases the protection of the monolith against moisture. Before starting work, it is recommended to carefully study the sequence of actions.

First of all, you should prepare the base of the foundation for waterproofing. To do this, you will need to clean it from dust and dirt. After that, you can start applying liquid waterproofing. It is important to remember that the finished undiluted mixture has a rather high viscosity, therefore it is customary to use special solvents to dilute it. If necessary, liquid waterproofing can be diluted with ordinary kerosene.

The prepared mixture is applied to the walls of the foundation and wait some time for it to penetrate deep into the concrete. This will strengthen the material and increase its hydrophobicity. At the next stage, the roll material is installed on a monolithic foundation. The laying technology takes into account that the waterproofer should protrude from the structure by about 10-15 cm.

Helpful information! It should be noted that the waterproofing material is overlapped.

In this case, bituminous mastic is required to be applied to the joints. It is very important that the material lies flat - there should be no waves on the canvas. After laying the first layer, you can proceed with the installation of the second.

Insulation of the foundation slab: a step-by-step guide

Warming of concrete is a necessary measure, which is aimed at protecting the monolithic structure from the effects of low temperatures. Arrangement of competent insulation allows you to increase the operating life of the slab. Traditionally, expanded polystyrene is used for insulation. It is very important to choose the right material: PPP must be extruded.

The thickness of the insulation depends on the climatic conditions. This indicator varies from 10 to 15 cm. During insulation, you need to be careful in order to correctly perform this work on the foundation slab. The technology for this process is quite simple.

It is important to remember that you cannot use only one layer of PPP for insulation. As a minimum, it is recommended to lay two layers. In some cases, this number is increased by one more point. The exception is the PPP slabs, which have locks in the form of the Latin letter "L" - they can be put in 1 layer.The number of layers is reflected in the final price of a monolithic slab foundation.

During installation, do not forget that the seams formed during the work require overlap. This is due to the fact that cold bridges are formed in such places. Of course, this procedure takes additional time, but its implementation will save on heating the house. After installing the PPP, a polyethylene film (necessarily dense) is laid on top of it, on which the heat-insulating material will be installed.

DIY foundation slab reinforcement - what you need to know

After the waterproofing works, as well as the organization of thermal protection of the future monolith, the reinforced frame is assembled. Perhaps this is the most problematic stage of work for beginners. It is rather difficult for an untrained person to master the technology of fastening individual elements in a grid. Before proceeding with the assembly of the frame, it is recommended to study the video materials on this topic.

For the assembly of the frame, as a rule, ribbed bars are used, which correspond to class AIII. The cross-sectional index of such reinforcement is 12-14 mm. It is laid as follows: lengthwise and across with a step of 15 to 30 cm. As mentioned above, depending on the thickness of the foundation slab, there can be 1 or 2 layers of reinforcement.

To assemble the reinforcing frame, it is necessary to select rods of the required size - in this case, the foundation will have sufficient rigidity

In order for a monolithic foundation slab to acquire the necessary strength with your own hands, you need to correctly calculate the number and size of rods at the design stage. The distance from the edge of the plate to the metal elements must be at least 5 cm.

Note! In order to provide the required distance, the fittings are assembled on special supports.

When laying the reinforcement, a checkered pattern is obtained. The intersections of the longitudinal and transverse rods are held together by soft wire made of steel. To twist the wire, you need to purchase a special hook. With it, the process will be greatly accelerated. There is another option for connecting rods in the mesh of a monolithic foundation. The technology involves the use of special plastic clamps. However, this connection method is not as widespread as the previous one.

It is important to remember that experts categorically do not recommend using welding to connect the rods. fittings... The fact is that the weld has a very low resistance to rust.

Monolithic foundation slabs, as a super-strong base, are used for the construction of columns and support structures

How to fill a monolithic foundation slab with concrete

Pouring is the key to creating a slab foundation for a home. This process must be performed as correctly as possible, in compliance with the technologies and rules that are indicated in the corresponding construction documentation. Only high quality concrete should be used for pouring. The following brands are suitable: M-300 and M-400. In any case, concrete below the M-200 grade cannot be used.

Filling the foundation slab with your own hands is not recommended, since concrete must be loaded into the prepared foundation pit in such a way as to fill it in one go. Today it is easy to easily rent special equipment (concrete mixer). Of course, you can fill it yourself, but the strength of the finished structure in this case may decrease.

A very important point is the compaction of the concrete during pouring. For this, a special tool is used - a vibrator, which eliminates bubbles inside the concrete solution, thereby compacting it. After pouring concrete into the pit, bounded by the formwork, it must be carefully leveled.

Another point to pay attention to when pouring the foundation slab with your own hands: during operation, no butt joints should form. They arise if one part of the concrete poured into the pit has already frozen, and the pouring is still in progress. Finally, it is necessary to carefully level the surface of the mortar. Subject to all these rules, the foundation slab will turn out to be solid and of high quality and will last more than one year.

Pile-monolithic foundation: organization features

The foundation, which is installed on the piles, differs from the monolithic one not only in the technology of installation, but also in cost. The price of such a building foundation is more acceptable. Thus, the pile foundation allows you to save on the construction of a residential building.

Note! In this case, piles or pillars are not strong enough. In order to increase their rigidity, they are strapped (connected to each other).

There are several technologies for connecting individual columns. The grillage foundation is very popular. A monolithic pile foundation of this type can be carried out using two technologies: joining the connecting tape underground and above it. The choice of the pile-monolithic type of foundation is advisable in the following cases:

- if there is problem soil on the site where construction work is being carried out;

- in the case when the house is being built in the coastal zone;

- if the building is on a slope;

- to save money.

Monolithic supports can be equipped with your own hands without the use of special equipment. This makes them very popular. A monolithic foundation with a grillage is distinguished by its versatility and democratic cost.

Before starting the installation of such a structure, it is recommended that you familiarize yourself with the video materials on this topic. It should be noted that pile-monolithic structures are distinguished by a long service life.

Recommendations for the care of concrete for self-assembly of a monolithic slab

In order for the concrete to harden safely, a high humidity level of 90-100% and a temperature above 5 ° C should be provided. It is recommended to wait for warm weather, starting from 20 ° C, in order to fill the stove. It is this temperature regime that is ideal for hardening. Caring for a monolithic concrete slab is simple: you need to protect it from damage and maintain the required level of humidity. If necessary, you can entrust the creation and maintenance of the foundation to professionals by ordering a turnkey monolithic foundation slab.

After finishing with laying, the concrete must be covered with a film. This will provide protection from heat and wind. The film itself should be converted into large panels. Then lay the resulting strips with an approach of 10-15 cm and glue them with tape. It is important to minimize the number of bonded areas so that the tarp or sheeting is 1-2 pieces. Individual elements of the panel should cover each other by at least half a meter.

You will need a film of such a size that it can cover the side of the formwork, and on the edges of this covering, you can install a load - protection from the wind. In addition, with this weight, whether it be boards or something else, you need to press the intersection of the parts of the tarpaulin or film. This will reduce windage. For the same purpose, the boards can be spread over the entire surface of the monolithic foundation for the house.

The design features of a monolithic foundation allow to guarantee the strength and stability of the building, regardless of the type of soil

If the air temperature is more than 5 ° C, 8 hours after pouring the concrete must be poured with water. This should be done by drip, not jet.To prevent the surface from being damaged by drops, you can lay burlap on top and cover with foil. According to this technology, only the material with which the stove is covered is watered, and this, in turn, helps to maintain the necessary humidity.

Helpful information! If you know that frosts are expected, the concrete needs to be additionally insulated. For this purpose, any materials are suitable that allow you to keep warm: from those presented in hardware stores to a variety of improvised means (sawdust, straw, etc.).

When should you remove the formwork? If you have a monolithic slab, experts recommend removing it after the concrete has reached 70% strength. The specific time depends on the temperature at which hardening occurs.

A monolithic structure used as a base for residential buildings is a very reliable and durable structure. However, it is quite expensive and requires a flat surface. In the case of self-installation of such a reinforced concrete slab, it is recommended to study the video materials on this topic.