To strengthen the structure, protect it from the negative effects of the environment, extend the period of operation and create a presentable appearance, the external facing of the building is performed. The most popular technology is the ventilated façade system, which addresses both aesthetic and utilitarian functions. The features of the popular decorative finishes can be found in this article.

Content

- 1 Ventilated facade: what is this method of decorative and protective finishing

- 2 Ventilated curtain wall system design

- 3 Distinctive advantages of a curtain-ventilated facade

- 4 Frame material for creating a ventilated facade system

- 5 Features of designing a ventilation facade

- 6 Varieties of ventilated curtain wall systems

- 6.1 Installation of ventilated porcelain stoneware facades

- 6.2 Fiber cement and aluminum slabs for ventilated facades

- 6.3 Ventilated facade system made of metal cassettes

- 6.4 Ventilated façade cladding with НPL-panels

- 6.5 What are the facades of a building made of ceramic materials

- 6.6 Other options for cladding materials for a ventilated building facade

- 7 Ventilation facade installation technology

Ventilated facade: what is this method of decorative and protective finishing

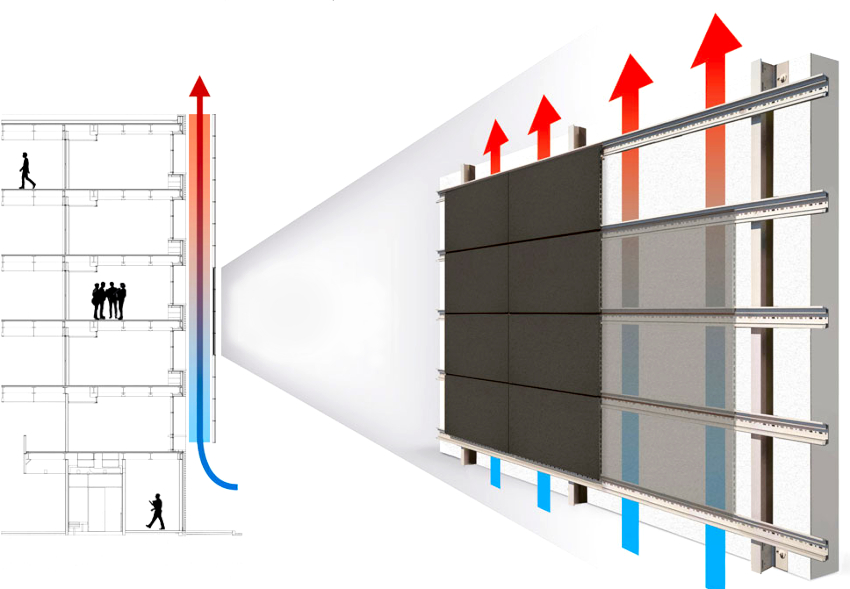

The first step is to figure out what a ventilated facade is. It is represented by a multi-layer structure, which is attached to the outer part of the building wall using profiles and bolts. An air space is provided between the surface of the structure and the layer of finishing materials in order to ensure air exchange to protect the wall from moisture accumulation and reduce the heat transfer of the house.

The ventilation facade provides not only reliable protection of the building, but also an optimal microclimate of the internal space

Installation of a ventilation facade allows you to solve several problems at the same time. Such cladding provides reliable protection of the structure against the negative and destructive effects of moisture, temperature changes, and wind loads. It helps to reduce energy costs by incorporating a thermal layer in the tiling cake. This finish improves the sound insulation of the interior space, extends the period of operation of the building.

A ventilated facade is not only a protective shell of a building. It also performs decorative functions. Thanks to a wide range of colors of finishes, it is possible to recreate a unique, inimitable and presentable appearance of the building, bringing to life unusual design solutions.

The ventilated facade system can be used for cladding both private buildings and multi-storey residential buildings. It is actively used in public and industrial facilities, technical premises of bus stations, commercial buildings, gas stations and other facilities.

The ventilated facade system is installed both on private buildings and on multi-storey residential buildings

Ventilated curtain wall system design

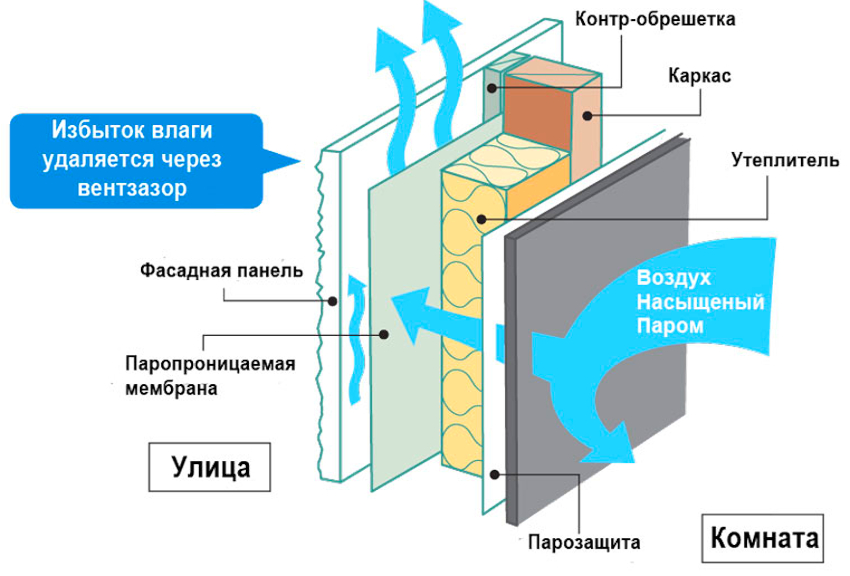

The ventilated facade of the house consists of the following layers:

- wireframe subsystem;

- insulating layer;

- circulation gap;

- outer decorative shell.

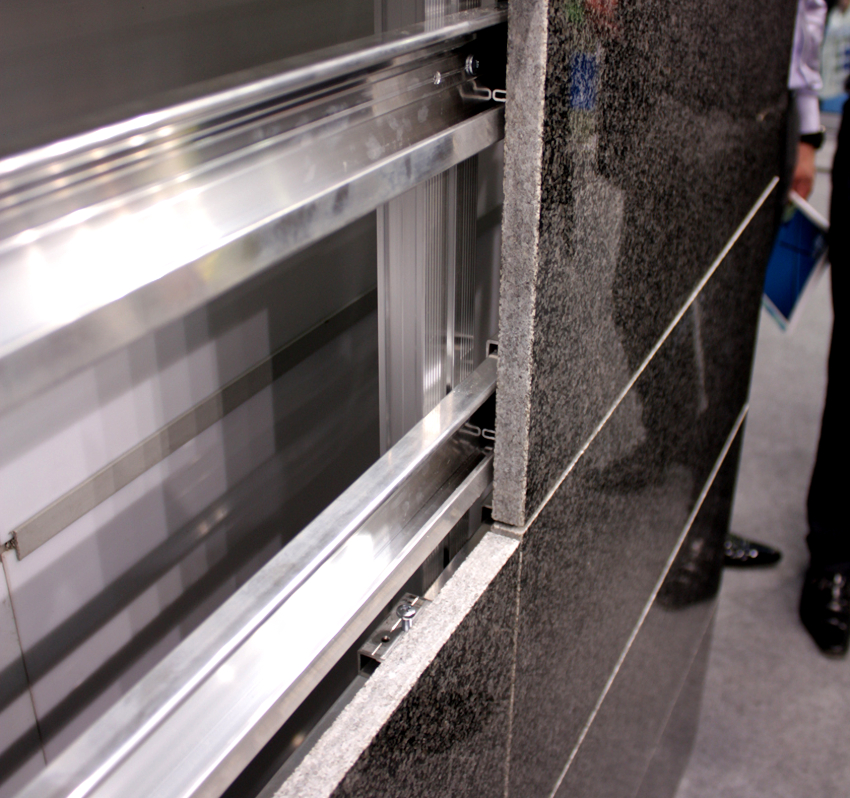

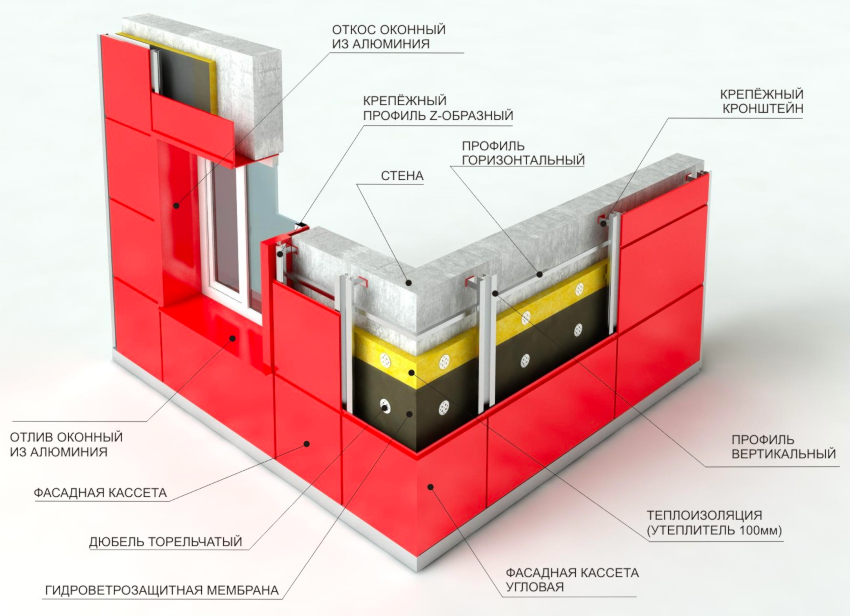

The frame subsystem for the ventilation facade is the bearing support for the entire decorative and protective structure. It is securely attached to the wall using special elements. The frame consists of extruded aluminum elements in the form of bearing profiles and brackets, which are fixed to each other with rivets, anchor bolts for fixing to the wall and cladding fixing elements. For this, clasps for porcelain stoneware, sleds and ikli - for facade cassettes, rivets - for fiber cement and other options can be used.

Guide bearing profiles are used for fastening finishing materials. They can be T-, U- and L-shaped, 3-6 m long, depending on the type of finish and installation method. The profiles are attached to the wall using brackets. Thanks to the elements, you can adjust the gap between the wall surface and the finish, which is especially important for uneven substrates. The brackets can be supporting or carrying. They must have a large bearing capacity, which is necessary to be able to withstand the weight of the sub-system and cladding.

The ventilated façade system is a multi-layer structure, which is attached to the outer part of the building wall using profiles and bolts

The subsystem in the form of a single frame for further fastening of the cladding ensures a strong connection of all layers of the facade, simultaneously performing the function of transferring the weight of the cladding elements to the walls of the building, preventing vibration.

Ventilation facade construction: insulation and decorative layer

The insulating layer is a multifunctional component that carries out wind, steam, heat and waterproofing of the outer wall surface. Several different materials can be used here, or one universal material that performs several functions at the same time. It is selected on the basis of compliance with the requirements of thermal insulation, waterproofing, fire resistance and noise insulation.

Thermal insulation of a ventilated facade can be carried out using mineral wool, polyurethane foam or foam. The layer thickness must be at least 100 mm. The insulation layer is fixed to the walls using mechanical bolts.

The outer decorative shell of the ventilation facade protects the lower layers from possible mechanical damage

Important! Do not use glue to install the insulating layer, as it will not ensure proper adhesion of the material to an uneven wall surface.

A vapor barrier film is laid on the thermal insulation coating, which protects the insulation from moisture penetration, while maintaining the efficiency of condensate evaporation into the environment.

The circulation gap is represented by the space between the wall and the decorative finish, due to which normal air exchange is ensured, preventing the accumulation of moisture between the surfaces. Its value can be in the range of 1-10 cm, which is determined by a special calculation based on the values of temperature, speed of movement of air masses and the coefficient of heat transfer of the structure.

To create good permeability of air masses, ventilation grilles with protective holes are mounted in the lower and upper parts of the cladding to prevent foreign objects from entering the structure cavity.

The construction of the ventilated facade is completed with the installation of an external decorative shell, which protects the lower layers of the ventilated facade from all kinds of mechanical damage, the negative effects of natural processes and gives the structure a complete presentable look.

Distinctive advantages of a curtain-ventilated facade

The wide popularity of hinged ventilated facades for a private house and multi-storey buildings is due to a number of distinctive advantages of finishing. System installation is quick and easy. Since there are no wet processes during the work, finishing can be done at any time of the year. The protective and decorative structure is predominantly lightweight, which eliminates the creation of additional load on the supporting elements of the building. The ventilated façade system contributes to the extension of the operational life of the structure, which on average is 50 years.

Important! If the implementation of the curtain facade is envisaged at the design stage, then it is possible to reduce the thickness of the outer walls, which can simultaneously lead to an increase in the usable area of the internal premises, and reduce construction costs.

The ventilation façade contains an insulating layer, which contributes to the creation of a favorable indoor microclimate, improving the heat and sound insulation characteristics of the load-bearing walls. This simultaneously leads to a decrease in the cost of operating the facility in terms of air conditioning, ventilation and heating. The ventilation façade provides reliable corrosion protection for the metal elements of the building.

Other advantages and disadvantages of a ventilated facade

For the installation of a hinged ventilated facade, no special wall preparation is required. It is enough to eliminate significant surface defects, to close up visible cracks. Wall alignment is not performed, since the adjustment is usually carried out at the stage of installing the subsystem. The ventilated facade technology can be used both on newly erected structures and in the reconstruction of old buildings in order to stop their further destruction from moisture, wind loads and other negative factors.

Important! To create a ventilation facade, materials are used that have high fire safety and fire resistance, which excludes the possibility of fire in the structure.

It is worth remembering that errors in the installation of a ventilation facade cause a decrease in the heat resistance of the walls, anti-corrosion protection and a violation of ventilation

The facade does not need periodic repairs, except for the replacement of the decorative layer as a result of its mechanical damage. The finish is characterized by ease of maintenance, which involves simple cleaning of the surface under the pressure of water. A variety of colors and views makes it possible to decorate the exterior of the building in any architectural direction.

It should be remembered that the wrong ventilation facade installation technology can turn advantages into disadvantages. Installation errors cause a decrease in corrosion protection, ventilation and heat resistance of the walls. An improperly organized subsystem can lead to whistling in high winds.

When performing work, special attention is paid to the correct fastening, strength and reliability of the fasteners, the step width of the system.The technical characteristics of the building and the safety for the surrounding people will depend on the selected materials, which must correspond to the main parameters of the structure.

Frame material for creating a ventilated facade system

Ventilated curtain wall systems are usually classified by the type of external cladding, namely by the material used for decoration. The method of installation work and the choice of a subsystem depend on the type of material.

It is better to use metal structures as a frame, which are distinguished by their reliability, strength and durability. Galvanized, aluminum and steel subsystems can be used here. The first option is the embodiment of the optimal combination of functionality and affordable cost.

The aluminum profile for a ventilated facade is characterized by a higher price, but has some distinctive advantages during installation, which becomes possible due to the low weight of the structure, which has anti-corrosion properties.

Important! The frame is mounted using brackets with oval holes, which act as expansion joints to give the system a stroke during the thermal expansion of the metal.

The stainless steel subsystem has good strength and corrosion resistance. It is characterized by ease of installation and low cost in comparison with other metal counterparts. The system is fixed in a fixed way.

For the arrangement of ventilated facades for cottages, a wooden subsystem is mainly used, which is distinguished by its strength, durability, environmental friendliness, low thermal conductivity, ease of installation and aesthetic appeal. However, the material is susceptible to moisture and fire. To exclude such consequences, it is necessary to organize additional protection of the structure.

Related article:

Facade clinker tiles: a versatile cladding material

The main advantages and disadvantages of the product. Material selection rules. Areas of application. Thermal panels and panels with clinker tiles without insulation.

The subsystem can be attached to the wall horizontally, vertically or horizontally-vertically. The second option is the most rational, since it promotes natural air circulation in the ventilation gap and is less metal-consuming.

Features of designing a ventilation facade

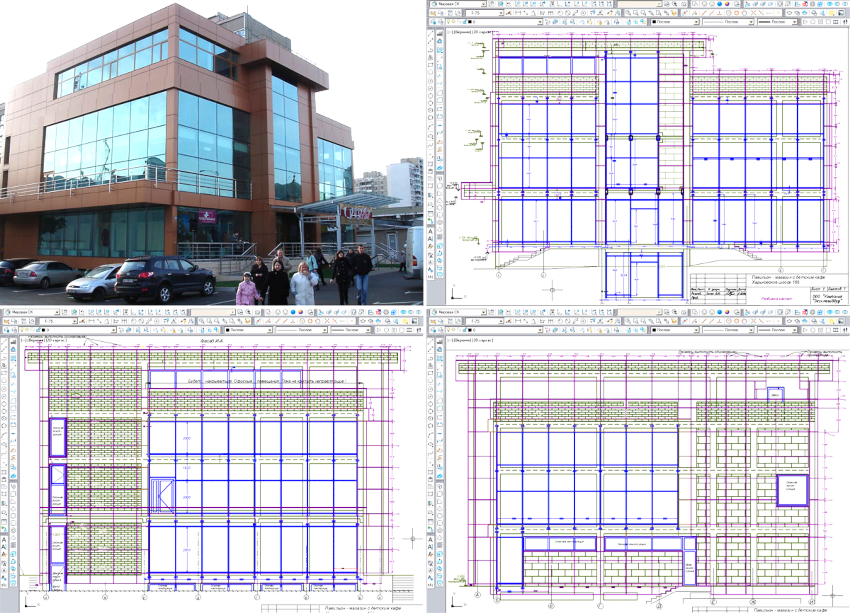

The design of the ventilation facade is carried out taking into account the layout of the structure, its appearance and design features. It is best to entrust the development of the project to specialists, which will guarantee the durability and attractive appearance of the building facade.

The detailed design of the ventilated facade should include indicators of the static strength of the system, calculation of the technological characteristics of the facade, the layout of the finishing elements, drawings for the installation of the subsystem, the attachment points of the facade structures, the number of frame elements, insulation and finishing material, an explanatory note describing the technology for performing the work.

When designing a ventilation facade, it is necessary to take into account the layout of the building, its appearance and design features.

One of the most important design stages is the calculation of a ventilated facade in relation to the value of static loads, which is carried out on the basis of SNiP in two approaches. The first involves the use of a linear spectral technique, and the second is the calculation of a structure with high humidity.

Weight loads are one of the main types that differ in the type of finishing material and the height of the building.Wind loads depend on the characteristics of the environment, the height of the building and the wind area of the area. Their calculation is carried out on the basis of SNiP "Loads and Impact". Ice load is a short-term phenomenon, but it should not be neglected, as it can exceed the weight of the cladding itself.

Varieties of ventilated curtain wall systems

Natural stone, porcelain stoneware, fiber cement, perforated metal cassettes, glass panels, clinker bricks, Rock panels, HPL panels, volumetric terracotta ceramics can be used as finishing materials for a ventilated facade. The choice is determined by the technical conditions of installation, financial capabilities and aesthetic requirements.

The ventilated facade made of porcelain stoneware is very popular. This is an artificial stone that is obtained from a special mixture by pressing and subsequent firing. The material is distinguished by strength, durability, wear resistance, frost resistance, fire safety, environmental friendliness, resistance to temperature extremes, chemical environment, negative effects of sunlight, which does not affect the original brightness of the material.

HPL panels, natural stone, metal cassettes, glass panels, clinker bricks can be used as decorative cladding.

Porcelain stoneware is characterized by good sound and heat insulation properties. The material is not subject to rotting and the formation of mold and mildew. It is undemanding to care for. Porcelain stoneware is the ideal solution for the decoration of residential, industrial and office buildings. The material is available in a wide variety of colors and tile sizes, which allows you to create an attractive facade in a short period of time. The tiles can be matte, polished, satin or structured.

When choosing the dimensions of a product for cladding a ventilated facade of a building, it is important to take into account some features of the material. The larger the size of the products, the more difficult their installation. Elements that are too small can create a checkered leaf effect. The tiles must be of the same size, otherwise it will be difficult to calculate the required amount and install the guides.

An important disadvantage of porcelain stoneware is its significant weight, which creates an additional load on the supporting elements of the building. The material is also distinguished by its high cost, which is compensated for by the durable operation of the facade.

Helpful advice! The most convenient size of porcelain stoneware tiles for the facade of a building is 60x60 cm (with a minimum thickness).

The larger the size of the products for cladding a ventilated facade, the more difficult their installation

Installation of ventilated porcelain stoneware facades

Porcelain stoneware can be fixed in an open or closed way. For the first option, clasps are used, which remain visible after the installation is completed. The first step is to mount the lower fasteners, on which the plate is placed. Next, two upper clasps are attached. Each element has two lugs that hold a pair of adjacent tiles.

The second method is more complicated and expensive, but such fasteners are invisible. You can use a combined version, in which the clasps are located at a certain height, due to which they are invisible to the eye. In Moscow, a ventilated facade is often installed using this method.

Concealed fastening is carried out in two stages. In each tile, in its lateral part, cuts are made pointwise or along the entire length. It is necessary to insert latches into the holes, which are fixed to the profile with rivets or bolts.

The layout of tiles in relation to the elements of the facade can be strict, non-strict, mixed or made with cutting corners.In the first case, all the seams of the facing material are located on one straight line with the elements of the facade. The second option assumes vertical or horizontal matching. The price of a ventilated facade made of porcelain stoneware will average 3.2-3.5 thousand rubles. per sq. m depending on the installation option.

Fiber cement and aluminum slabs for ventilated facades

Another popular material for ventilated facades is fiber cement, which is a slab of cement and a special fiber component. The latter provides elasticity to the product, while increasing its resistance to negative mechanical stress. Fiber cement board has an attractive appearance that remains intact for many years. The material is characterized by good heat and sound insulation. Low cost.

Fiber cement boards are distinguished by fire resistance, heat resistance, resistance to biological, chemical and mechanical negative influences. The material is presented in a wide variety of colors and shades, which allows you to create unique presentable facades. There are also options that mimic any material.

From the disadvantages of this method of cladding, one can single out the lack of options for carrying out installation work. There is only one method that involves placing the elements on the outside. Price per m² the ventilated facade will average 3.5 thousand rubles.

Composite aluminum plates are cassette products consisting of two sheets of metal, between which there is a polymer layer. Fastening of the material is carried out in a special way with the obligatory arrangement of the interpanel joint, which provides reliable protection against moisture. The ventilated facade made of composite panels is characterized by strength, durability and resistance to negative environmental influences.

The panels are presented in a wide variety. They differ in the thickness of the cassettes, workmanship and degree of fire resistance, which directly affects the cost of the cladding. The price of a ventilated facade made of aluminum composite panels is about 4 thousand rubles. for 1 sq. m.

Helpful advice! Aluminum composite panels are flexible, therefore they can be used for cladding facades of complex architectural forms.

Ventilated facade system made of metal cassettes

Another popular type of ventilated facade is metal cassettes, which are products made of galvanized steel, which have a colored galvanized coating. The cassettes are painted in the factory, which provides a solid base that is resistant to the negative effects of atmospheric precipitation and mechanical damage. Elements have rounded corners. They can be rectangular, trapezoidal, U-shaped or triangular.

Helpful advice! The most presentable view of the building can be obtained by using metal cassettes in copper or brass colors.

Such a finish shows resistance to temperature, mechanical and negative natural influences, over a long period of operation it is able to maintain its original attractive appearance. The material is self-cleaning. During precipitation, dust and dirt that have accumulated on the surface of the finish are easily washed off. Metal cassettes are lightweight, which has a positive effect on the cost of installing a ventilated facade.

Metal cassettes for the facade are produced perforated, volumetric or multi-colored.The first option can be equipped with internal LED lighting to create unique facades. Volumetric elements can give a building a futuristic look. They are pointed, wavy, conical, or honeycomb. Metal cassettes can have a single color or polyester spraying, creating a metallic or chameleon effect.

Metal panels are fixed in an open or hidden way. In the first case, each cassette is fixed with self-tapping screws separately. The panels are attached to the vertical profiles of the frame, overlapping. Concealed mounting is used for thin cassettes. Their upper part is fixed to the lathing, and the lower edge snaps into the element of the lower row. Such cassettes are equipped with one fold located at the top, which serves as a junction with an adjacent panel. The price of a ventilated facade made of metal cassettes will average 3.8-4 thousand rubles. behind m².

Ventilated façade cladding with НPL-panels

New in the domestic market are НPL-panels, which have high performance characteristics, light weight and are characterized by an attractive appearance. For the production of the material, multilayer paper and wood fiber are used. Thermosetting resins are introduced into the molding mixture, which give the finished product solidity, eliminating the possibility of delamination.

To protect the panels of the ventilated facade from burning out in the sun and abrasion as a result of wind influences, the elements are covered with a special acrylic varnish. The thickness of the products is 0.5-25 mm.

Important! Composite panels can be used not only on walls, but also when cladding ceiling structures.

НPL-panels are distinguished by high sound and heat insulation characteristics, a large variety of colors. The material has self-cleaning properties, so it can be safely used for finishing multi-storey buildings. Panels for the facade of the house have increased strength, resistance to mechanical stress, moisture resistance, resistance to aggressive environments. Due to the high density of the material, dust and dirt do not get into the structure of the product, excluding the possibility of the formation of microorganisms.

The panel assembly process is simple and time-consuming. The main disadvantage is the high price of the type of ventilated facade, where НPL-panels are used, which is 6 thousand rubles. behind m².

The panels can be fixed visually with rivets and in concealed versions using Keil collet type anchors or Duro PT concealed fastening.

What are the facades of a building made of ceramic materials

Bulk terracotta ceramics are widely used for a ventilated facade system, for the manufacture of which fired clay of various shades is used, which depends on the location, the result of mixing the components and the method of firing. The manufacturing process takes about 10 hours at a temperature of 100 ° C, which contributes to the production of particularly durable facade ceramics, which retains the natural texture. This cladding is environmentally friendly, fireproof and resistant to temperature extremes, moisture and mechanical stress.

The tile is additionally coated with a special compound, which gives the material increased strength. In addition, such an impregnation protects products from the destructive effects of microorganisms. Price of work for m² ventilated facade averages 4.5-5 thousand rubles.

Another material for creating a ventilated facade is clinker bricks, which are made from clay, quartz, mica, iron oxides and kaolin.The material is characterized by high strength, wear resistance, resistance to moisture, chemicals and ultraviolet light, frost resistance, environmental friendliness and high cost. Such a brick has grooves on the back side, with the help of which it is fixed to a profile with ridges. The clinker brick engages and sits on the ventilated facade.

The cladding made of bulk terracotta ceramics is environmentally friendly, fireproof and resistant to mechanical stress

The disadvantages of clinker bricks for the facade include significant weight, which increases the load on the load-bearing elements of the building and necessitates the use of reliable anchors for fixing the profiles. The material has small dimensions, which are equal to 150x300 mm. This makes the installation of products more laborious and time-consuming, which significantly increases the price of the ventilated facade, which is 4 thousand rubles. behind m².

Other options for cladding materials for a ventilated building facade

Often, when arranging ventilated facade systems, natural stone is used, which is characterized by high technical and operational characteristics. The main disadvantages of the material include the significant weight and high cost of installing a ventilated facade, amounting to 6.5-7 thousand rubles. behind m².

Agglomerate tile is used as an artificial analogue, which is made of cement and stone chips. The advantages of the material include high strength, durability, fire resistance and precise geometric shape of the elements.

Important! Finishing made of natural or artificial stone requires a solid and reliable stainless steel subsystem.

As panels for the facade of the house, you can use impact-resistant, heat-resistant, bullet-proof glass with additional reinforcement using aluminum panels that can be painted in any color. Such panels can be colored, transparent, semi-mirror, laminated or have other specific features. Glass can be coated with glass enamel, which makes it possible to obtain a coating with imitation of stone, wood, or with a decorative pattern.

The material is characterized by strength, reliability, durability. It is able to give the facade of a building an unusual aesthetic appearance, allowing it to embody bold design ideas. Despite the good technical and operational properties, the material has a high cost, which is 5.5-6 thousand rubles. behind m², and the complexity of installation work.

Ventilation facade installation technology

At the first stage of doing a ventilated facade with your own hands, you should mark the surfaces based on the project or diagram. Beacons are placed along horizontal and vertical lines, with which you can correct uneven sections of the wall. Then, the mounting of the bearing profiles is carried out using brackets fixed to the wall with anchor bolts. For this, holes for dowels are pre-prepared.

After the installation of profiles and brackets, as well as the laying of the thermal insulation layer, the installation of decorative cladding is carried out

Important! For a reliable connection, paronite gaskets are used.

After the installation of the profiles and brackets, they begin to arrange the heat-insulating layer. If two or more materials are used, the one that has a lower density and a looser structure is laid first, and more dense slabs on top. The insulation is fixed with special dowels with caps in five places.A vapor barrier film is laid on top of the insulation, which will protect the thermal insulation layer from moisture and be an additional wind protection of the building.

Next, the installation of decorative cladding is carried out, which can be done in an open or closed way. For the first option, clasps and rivets are used to fix the finishing material, and for the second - secret clips, clasps and pins. The cost of a ventilated facade directly depends on the type of decorative finish.

The ventilated facade is a modern solution for building cladding. It protects the building from negative environmental influences. In addition, such a finish is a presentable decorative shell for any type of structure, as clearly shown in the photo of ventilated facades.