The desire to have a solid brick house is not realized? Take your time to part with the dream. Modern finishing materials can work a real miracle: using brick siding for outdoor decoration, even a dilapidated wooden structure can be turned into a modern architectural structure. It is only necessary to choose the right panels that will protect the house from winds and dampness, and also make its design presentable.

Content

- 1 Siding house: reliability and aesthetics

- 2 Modern types of siding for exterior home decoration

- 2.1 Brick cladding panels: features, prices

- 2.2 Stone siding for exterior decoration: photos and prices

- 2.3 Fiber cement siding for brick: the difference in external coatings

- 2.4 Vinyl siding for a brick: what to look for when buying

- 2.5 Basement siding for brick: specific application

- 2.6 Metal siding under a brick: advantages and disadvantages

- 2.7 Red brick siding: a sought-after classic

- 3 Siding sizes for bricks from different manufacturers

- 4 Siding selection: prices, samples and material testing

- 5 Brick siding for outdoor decoration: installation method

- 6 Which is better: brick the house or sheathe it with brick facade siding

Siding house: reliability and aesthetics

Any home should not only be comfortable and aesthetic inside, but also externally make a pleasant impression. And here you cannot do without finishing. Plastering and painting of walls give good results, but such a coating has a rather limited period of aesthetics. Siding is a good alternative to the above method of decorating the facade parts of buildings.

Decorating houses with siding for brick, stone, wood is gaining more and more popularity. And this is no coincidence, since the panels in terms of quality and installation process seriously compete with natural materials used for cladding buildings. With siding, everything is much simpler, since you do not need to have the professional skills of a bricklayer in order to remove an even seam or prepare a solution of the required consistency and optimal composition.

In terms of external indicators, siding is not only not inferior to brick or stone, but also largely surpasses the material (especially brick) in terms of preserving aesthetics: for example, it does not have a whitish coating, like on a red brick, or small traces of chips, like on white silicate.

And the price of brick siding is lower than the cost of stone material. And the ability to install the panels yourself makes the cladding process doubly cost-effective.The air gap appearing between the wall of the house and the panels provides ventilation to the outside of the building, and also helps to retain heat in the premises.

Determining that the house is sheathed with siding, and not bricked, is most often possible only with careful consideration. Therefore, there is no reason to fear a "cheapening" of the appearance of the house when facing with panels.

Modern types of siding for exterior home decoration

Initially, siding was made from natural wood. The boards were laid from bottom to top, sometimes end-to-end; paint or varnish was applied to them as a protective layer. This coating is expensive and short-lived. In conditions of high humidity, the boards, after a certain amount of time, still lose their appearance and integrity.

In the demonstration photos, the decoration of houses with brick siding (or imitating other materials) is made from the following compositions:

- wood-pulp;

- vinyl;

- fiber cement;

- metal.

Wood-cellulose mixture is made of MDF type. Shredded wood is pressed under high pressure and temperature, resins are added to it for strength and moisture resistance. Externally, the coating has a pleasant appearance, it is inexpensive, but does not differ in durability.

The most popular is vinyl siding. The advantages of this material include:

- resistance to temperature extremes, ultraviolet light, humidity;

- variety of colors, high aesthetic qualities;

- low weight, ease of installation;

- non-toxic and does not support combustion.

It is very important that vinyl siding drains condensation on the outside. Among the shortcomings, we can note the possibility of mechanical damage with a significant impact, as well as high thermal conductivity, therefore, the use of insulation is required during installation. Many people prefer sheathing houses under brick with vinyl siding: it is affordable and labor-intensive, the structure becomes neat and presentable.

Important! Darker types of plastic siding panels are somewhat more expensive, as color stabilizers and a large amount of coloring pigments are added to them during manufacture.

Metal siding is a more expensive cladding material. It is made of zinc, steel or aluminum and is a metal that is primed and polymer coated. The top layer usually has a decorative embossing.

Fiber cement plastic is made from cellulose pressed with cement. The cladding material is heavy. It is with the help of such a composition that natural stone is most often imitated.

Brick cladding panels: features, prices

The desire for naturalness most of all explains the popularity of the use of brick siding. A brick house is perceived as a solid structure with straight lines of window openings, corners, balconies and other architectural elements. There are a large number of varieties of brick siding on the market:

- classic red brick masonry;

- soft pastel options, panels with pink and even peach shades;

- gray and brown "brick" for connoisseurs of visually heavy buildings;

- panels with combined "masonry".

Brick siding for exterior home decoration can be made of vinyl, metal and fiber cement. Depending on the material and manufacturer, the standard sizes of the panels differ. It is possible to highlight only the general dimensional indicators of the thickness of the products. Vinyl panels have a thickness of 0.7-1.3 mm, fiber cement panels - 6-35 mm; metal - 0.4-0.6 mm.

For home decoration, you can choose inexpensive panels of domestic production, for example, "Keramite". Outwardly, they resemble ceramic bricks.Sold in packs of 10, have the following dimensions:

- height (useful) - 45 cm;

- width (useful) - 105 cm;

- area (useful) - 0.427 m².

Among the imported options, it is worth highlighting the panels of the Canadian company Novik:

- height (useful) - 47 cm;

- width (useful) - 122 cm;

- area (useful) - 0.516 sq. m.

The price of one panel of siding for a brick of domestic production is 300-400 rubles. Imported products cost an average of 550-750 rubles per 1 piece.

Stone siding for exterior decoration: photos and prices

Among modern residential buildings, there are many buildings that are perceived as mansions. If you look at it, then these are sometimes the most typical architectural structures, to which a certain charm is given by finishing: houses are sheathed with siding under a stone. Photos on the Internet show an imitation of cladding with white rubble stone, rather voluminous boulders, flat fragments, etc.

In general, there are several main types of stone imitation:

- granite;

- burnt stone;

- rubble;

- canyon.

It should be noted that more and more new design developments appear, so the above list may soon become incomplete.

"Stone" panel can be made of vinyl, metal and fiber cement. Metal and vinyl products are very similar in characteristics to panels that imitate brick, and repetition will be inappropriate. But it is worth dwelling in more detail on finishing made of fiber cement. It is this material that is more able to visually reproduce natural stone. It is also worth noting the extreme durability of the panels - only deliberate actions with the use of heavy tools can damage them.

As disadvantages, it is worth noting the high price, which is largely justified by the good performance characteristics:

- durability;

- resistance to temperature and humidity;

- providing thermal insulation of the building;

- high aesthetic qualities.

It will be useful to highlight another distinctive feature of siding with "bricks" that are visually similar to fragments of natural stone - the large weight of the panels: 1 m² can weigh from 16 to 40 kg.

Helpful advice! Before using for cladding fiber cement panels, be sure to make sure that the structure is resistant to additional stress.

As for the price, a panel of standard sizes 100x45x12 mm will cost (depending on the manufacturer) 1440-2000 rubles. The size of 3000x455x16 mm is quite common. Cladding with such panels is much faster, but requires the participation of at least two people.

Before finishing the house with fiber cement panels, be sure to make sure that the walls are resistant to additional stress.

Fiber cement siding for brick: the difference in external coatings

To have a correct understanding of fiber cement brick panels, it is worth taking a closer look at the process of their manufacture. Fibers of cellulose, asbestos, basalt or polymer are added to mortar or concrete. They are reinforcing components and provide high strength that reaches the index designated as seismic resistance.

In addition to the above components, in the manufacture of panels, microgranules in the form of bubbles are introduced into the composition. Their task is to provide the required density of finished products. For cladding low-rise residential buildings, it is recommended to use medium density siding. But for industrial premises, it is more expedient to use denser options.

The final stage in the production of fiber cement siding for brick is the application of an external coating. It can be either painting or ceramic spraying.It should be noted that many indicators depend on the final manufacturing process:

- panel weight;

- resistance to mechanical damage;

- price.

Siding under a brick with a ceramic outer layer is heavier, more expensive, it does not leave scratches after holding it over the surface with metal objects. Painted panels are much lighter, cheaper, but mechanically more vulnerable. The length of the fiber cement panels can be about 1000 or 3000 mm. The width varies from 38 to 1100 mm. The average price is 2500 rubles for m².

For the manufacture of fiber cement panels, fibers of cellulose, basalt and asbestos are added to the solution

Vinyl siding for a brick: what to look for when buying

Among vinyl panels for brick 80% are PVC products. Such material allows you to simulate masonry as accurately as possible. When viewing photos of houses under brick siding, you can only recognize the description of the image or by its belonging to a certain type of collections of design ideas.

Related article:

Brick facade panels: a good way to decorate a house without unnecessary stress on the walls

Main varieties and standards. The main advantages of installation. Review of manufacturers and product prices. How to install correctly.

A variety of "brick" shapes, textures, colors and shades allow you to choose panels for every taste. Material thickness ranges from 0.9 to 1.2 mm. The optimal size is 1.1 mm.

The composition of the material for the manufacture of PVC panels includes the following elements:

- calcium carbonate - the bottom layer that forms the structure of the leaf;

- titanium dioxide - makes up the outer layer (up to 10%);

- butadiene - stabilizes the mixture (1%);

- modifiers - define the properties of the outer coating.

Important! The more durable the outer coating, the more expensive the panel is. When buying a cheap option, you should understand that this significantly reduces the durability indicator.

In the catalogs of vinyl siding for the exterior of the house, prices can be found very different - from 240 to 800 rubles per panel. Much of the cost depends on the manufacturer. Most of the vinyl panels on the domestic market are imported products. Products made in Russia account for about 30%. In terms of quality, the latter in many respects are not inferior to foreign options, but as for diversity, there is still work to do.

Basement siding for brick: specific application

The definition of "basement" is very often used for the name of vinyl siding in general. To some extent, this is justified, since the manufacturing technology of these panels practically does not differ from any other vinyl covering used for cladding.

But there are still some differences. Plinth brick siding panels are used for cladding the bottom of buildings. Therefore, they have special operating conditions:

- more susceptible to mechanical stress, as they are in the ground zone;

- in contact with the foundation, which enhances the effect of moisture;

- carry a certain aesthetic function, being the visual basis of buildings.

Due to the increased mechanical impact on the basement siding, it must have a thickness of at least 1.3 mm

It is for the above reasons that basement siding cannot be less than 1.3 mm thick. Otherwise, the likelihood of damage is greatly increased.

When looking at a photo of brick siding, which manufacturers position as a basement one, it is easy to notice that with standard sizes the form panels are quite large. Regardless of the parameters and architecture of the building, the "bricks" of the walls should be smaller than those of the basement.

As for the color scheme, the basement panels are dominated by saturated and darker shades. They add completeness to the overall design of the house.

They are used for facing the basement area and fiber cement panels. It should be remembered that siding does not strengthen but protects and adds aesthetics. The strength of the foundation when using vinyl siding does not matter. But the cement option requires certain technical conditions.

Metal siding under a brick: advantages and disadvantages

You can decorate a facade under a brick using any type of siding, including metal. Should you give preference to this particular option? As mentioned above, such a siding is made of sheet metal with an external polymer coating applied to it. There are many advantages of this facing material:

- a variety of textures, shapes, shades;

- light weight;

- availability of installation;

- resistance to ultraviolet light, temperature extremes;

- ease of care.

With the help of metal siding, you can clad the most complex architectural elements, since there is no need to leave gaps for the expansion of the material.

Metal siding also has some disadvantages. And this is, first of all, the price. Catalogs of metal siding for outdoor home decoration offer samples of cladding material that mimics:

- clinker brick;

- smooth;

- "Old" masonry.

Almost all existing types of bricks can be seen on metal cladding panels. Manufacturing technology, namely the quality of the coating, most of all affects the price. The cheapest metal panels made of polyester coated steel have a price of 490 rubles per 1 m², which is twice as expensive as similar vinyl products.

The disadvantages of metal siding also include exposure to rough mechanical stress - the appearance of dents. Deformed panels cannot be restored.

Important! The above disadvantage is often used when it is necessary to veneer parts of a building with a complex architecture: you can bend the panel and get the required configuration.

Red brick siding: a sought-after classic

Red panels occupy a special place among brick siding. There are several reasons for this:

- firstly, this is a good old tradition: for a long time wooden houses in Russia were lined with just such a brick;

- secondly, the maximum similarity with natural material is most characteristic of such siding;

- thirdly, the manufacturing technology of this facing material allows you to set a reasonable price for it.

Red siding under a brick for external cladding of facades is produced by all, without exception, companies that are engaged in the manufacture of this type of finish. And this once again confirms its relevance.

Red brick houses look solid, austere and bright at the same time. They are perfectly set off by a green background in the spring and summer period, and the snow next to such buildings looks even whiter. Window decoration is most often contrasting, which positively affects the overall perception of the house as a whole.

Mostly red brick siding is made of vinyl or metal. These panels are lightweight. This factor greatly facilitates the cladding process. Panels that repeat the parameters of natural bricks are appropriate for sheathing almost all structural elements.

Siding sizes for bricks from different manufacturers

A house clad with brick siding, even when using a material that has a reasonable price, will not be cheap. It is very important to choose the right size of the panels, which will minimize the amount of waste. Each manufacturer has its own dimensional indicators.Below is information about the products of popular companies, indicating the size of the siding.

1. Alta profile. Has several collections:

- "Stone" - 1135х474х22 mm;

- "Brick" - 1130x468x17 mm;

- "Canyon" - 1158x447x20 mm;

- "Brick-Antik" - 1168x448x17 mm.

All panels are sold in sets of 10.

2. Vox. The lineup is wide, the sizes are different. The most popular are two collections:

- "Solid Moore" - 1110x460x2.5 mm;

- "Solid Stone" - 1110х477х2.5 mm.

Such a narrow width does not in any way reduce the performance characteristics of these German materials.

3. "Deke". It is worth highlighting two collections:

- "Berg" - brick siding (127x461 mm);

- "Stein" - siding stone (1196x426 mm).

4. Novik. Panels imitating "torn stone" - 1150x520 mm. Each panel has a specific structure.

5. "Weinstein" –795х595 mm. The manufacturer claims that the dimensions used in the manufacture of panels are optimal for cladding the facades of buildings.

Accurate measurements of the basement and wall parts of the building will help to correctly calculate the required number of sheets

Helpful advice! Before purchasing a siding, it is necessary to measure the basement and wall parts of the building. This will help you calculate the number of panels correctly.

Siding selection: prices, samples and material testing

The cladding of the house is designed for more than one decade. Manufacturers give a guarantee for 25-50 years, but this is in ideal conditions. No dwelling is insured against the effects of natural disasters, accidents and mechanical influences. That is why you should correctly approach the choice of siding, independently make sure of its high quality as much as possible.

When choosing, it is worth paying attention to some criteria.

Panel thickness. This is not about small or large numbers, but about uniformity. If the panel is not uniform, this is an important indication of poor quality. By the way, a large thickness is not yet a sign of durability, plasticity is no less important. An inflection can be an easy test for determining such an indicator. It can be done in the area of the mounting holes. If cracks or breaks appear at the place of the fold, the product should not be purchased.

Price per m² siding for brick and stone. The cost of panels depends on the manufacturer, quality and appearance of the products. In this regard, there is no need to be afraid to bother the seller with questions about the country of origin, the composition of the material (especially the outer coating), and the manufacturing technology. It is also worth remembering that cheap options are made using simplified technologies, which will definitely affect the quality.

Manufacturer. Both panels and fasteners must be from the same manufacturer. The desire to save on fasteners can be worth the loss of product warranty.

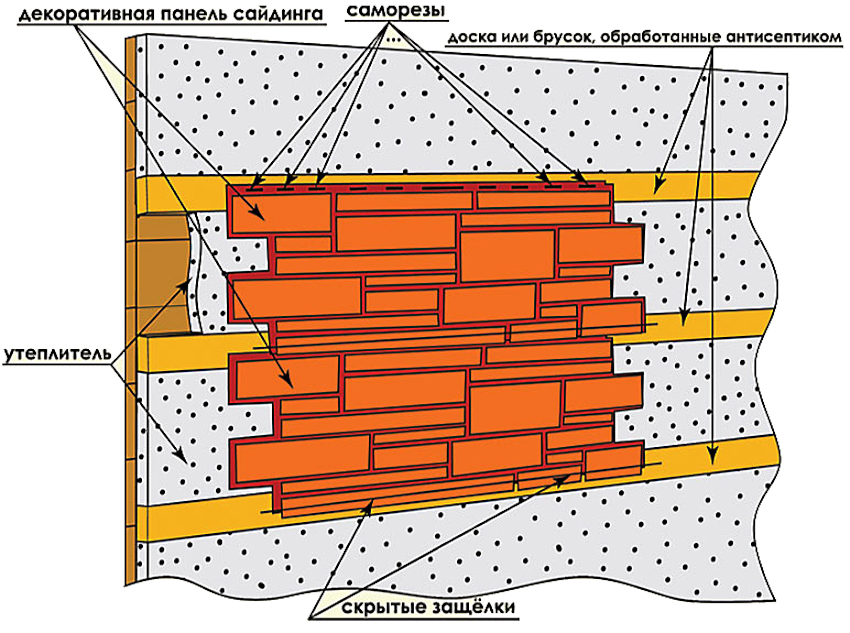

Brick siding for outdoor decoration: installation method

The photos of houses clad with brick siding presented on the Internet show us the ideal design of buildings. This is not necessarily the result of professional work. The panels are easy to install yourself. Subject to certain installation rules, the cladding can be as perfect as in advertising photographs.

When facing a house with metal siding under a brick, the following preparatory work must be performed:

- remove all additional elements from the outer walls of the house: antennas, gutters, ebbs, etc .;

- dismantle the old wall covering, apply a primer on them;

- mark the walls, put up beacons;

- carry out the lathing using metal profiles.

Important! When using insulation, the crate must be set so that a gap of 40-50 mm remains between the siding and the insulation.

Direct installation:

- The first panel is attached to the bottom bar, which must be perfectly aligned.The distance between the edge of the siding and the ground must be at least 50 mm.

- Installation of siding under a brick is carried out from the bottom up, the panels are attached to the guides.

- The connection between the panels is carried out using a mallet "in the lock". In the process of making the connection, it is necessary to ensure that the snapping occurs to the maximum depth along the entire length of the panel.

Experts recommend leaving a gap between the siding and self-tapping screws, which will provide additional ventilation.

Installation of siding panels is carried out from the bottom up, the sheets are attached to the guides

Which is better: brick the house or sheathe it with brick facade siding

It is worth drawing conclusions only after the object, subject or process, causing doubts, fluctuations, has been studied in detail. Further in the article, a comparative express analysis is proposed that will help you choose the right solution (whether it is worth bricking the house or sheathing with siding):

- Price. Brick siding for outdoor decoration is much cheaper and requires less financial costs for installation than brick. For many, this factor can be decisive.

- Weight. Old buildings do not always withstand the additional load, therefore, light (in comparison with stone and brick) siding in this case is the only suitable cladding.

- Low hygroscopicity. Siding does not absorb moisture like brick, even without treatment.

- Ease of installation. The manufacturer encloses instructions for any type of siding, following which anyone can independently perform the installation.

- Strength. No other type of siding can be compared to brick in terms of strength.

Any house lined with brick or clad in siding that imitates it is a modern building. It is up to everyone personally to choose the status of an artificial stone or to prefer simplicity, affordability and good appearance of the panels. It is worth considering the advantages and disadvantages of materials, as well as real financial opportunities.